Composite for grinding

A technology of composition and abrasive, which is applied in the direction of polishing composition containing abrasive, grinding device, grinding machine, etc., and can solve problems such as hindering disk capacity and excessive grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

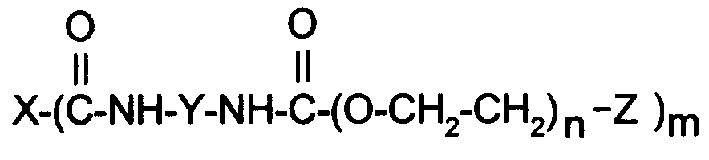

[0013] The polishing composition according to the first embodiment of the present invention is composed of a compound represented by the following general formula (1), a polishing agent, a polishing accelerator, and water.

[0014] In the general formula (1), letter X represents a residue of polyether polyol. Polyether polyols are preferably synthesized from compounds including active hydrogen atoms and alkylene oxides. The polyether chain of the polyether polyol preferably contains 20 to 90% by weight of oxyethylene groups. The letter m is equal to the number of hydroxyl groups in a polyether polyol molecule. Letter m is preferably an integer of 2-8. The letter Y represents a divalent hydrocarbon group. The letter Z denotes the residue of a monovalent compound with an active hydrogen atom. Specific examples of the letters Y and Z are polyaddition polymers formed by addition polymerization of at least one of ethylene oxide and propylene oxide and a lower alcohol or hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com