Production method of spheroidized graphite with low specific surface area

A production method and specific surface technology, applied in the direction of electrochemical generators, active material electrodes, electrical components, etc., can solve the problems of specific surface area and tap density contradiction, and achieve the effect of reducing the number of processing times and reducing electricity costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

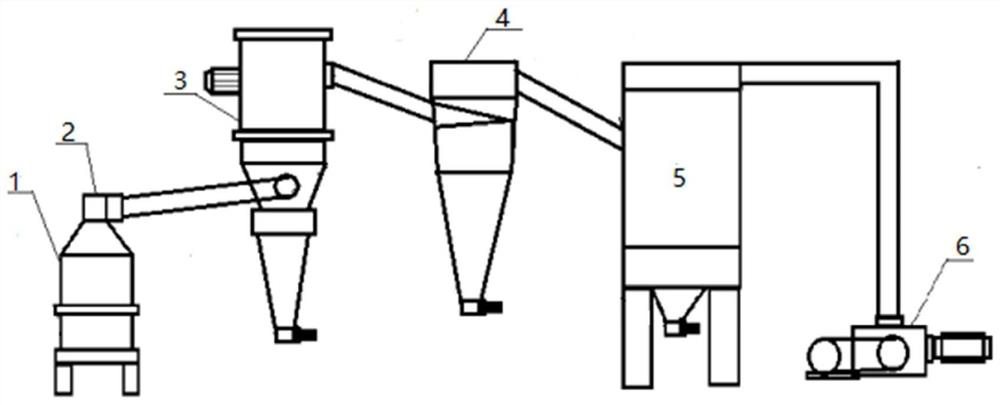

Method used

Image

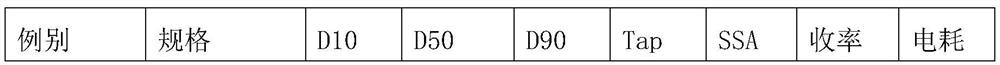

Examples

Embodiment 1

[0026] The production specification is SG17-0.96 spheroidized graphite, the quality index is D10: 10.4∽11.0μm, D50: 17.7∽18.6μm, D90≤31.0μm, Tap≥0.96g / cm 3 Specific surface area: 5.0∽6.0m 2 / g. The method in the patent of the present invention is used for production. The clockwise and counterclockwise rotation directions of the main engine 1 of the jet mill are 1:1 according to the processing times. For example, the 1st, 3rd, 5th, 7th, and 9th processing times are clockwise. Rotation, the 2nd, 4th, 6th, 8th, 10th processing times are counterclockwise rotation. Take flake graphite with a specification of -194, which is produced in Jixi Liumao Mine, put 500 kg of this batch of flake graphite into a 60-type steam pulverizer (the 60-type steam pulverizer is not equipped with an external classifier 3), and set the parameter as the main engine speed 45Hz, the speed of the fan is 35Hz, the speed of the internal classifier is 6Hz, the first stage of crushing is crushed once to D50 =...

Embodiment 2

[0033] The production specification is SG10-L spheroidized graphite, the quality index is D10=7.0±0.4μm, D50: 10.8~11.5μm, D90=17.5~18.8μm, Tap≥0.795g / cm 3 Specific surface area: ≤7.0m 2 / g.

[0034] The clockwise and counterclockwise rotation direction of the host grinding disc of the jet mill is 1:1 according to the processing times. Take the fine powder graphite with D50=10-14μm, the place of origin is Heilongjiang Jixiliu Wool, put 500 kg of this batch of graphite into the 50-type jet mill (both the 50-type and 30-type are equipped with an external classifier), and set the parameter as the main engine speed 45Hz, the speed of the fan is 33Hz, the speed of the internal classifier is 15Hz, after one crushing to D50=12.51μm; Mix one piece evenly, and then put it into the 50-type steam pulverizer repeatedly, set the parameters as the host speed is 35Hz, the fan speed is 30Hz, the inner classifier speed is 5Hz, the outer classifier speed is 90Hz, and the pulverizer is crushed...

Embodiment 3

[0040] The production specification is SG25-1.04 spheroidized graphite, the quality index is D10≥14μm, D50: 22∽24μm, D90≤35μm, Tap≥1.04g / cm 3 Specific surface area: 4.5∽5.2m 2 / g.

[0041] The clockwise and counterclockwise rotation direction of the host grinding disc of the jet mill is 1:1 according to the processing times. Take the -196 flake graphite produced by Haida Graphite Mine in Luobei, Heilongjiang, and put 500 kg of this batch of graphite into a Type 60 jet mill (Type 60 is not equipped with an external classifier). The speed of the classifier is 8Hz, after one crushing to D50=26.53μm; 2. Secondary crushing Collect the above-mentioned fine powder materials and micro powder materials crushed to D50=26.53μm into one piece and mix evenly, and then repeatedly put into 50 type air flow crushing In the machine, the parameters are set as the speed of the main machine is 34Hz, the speed of the fan is 31Hz, the speed of the internal classifier is 6.5Hz, and the speed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com