Electrolytic manganese dioxide screening equipment

A technology of electrolytic manganese dioxide and screening equipment, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of grinding machine burden and waste, and achieve the effects of reducing burden, convenient operation and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

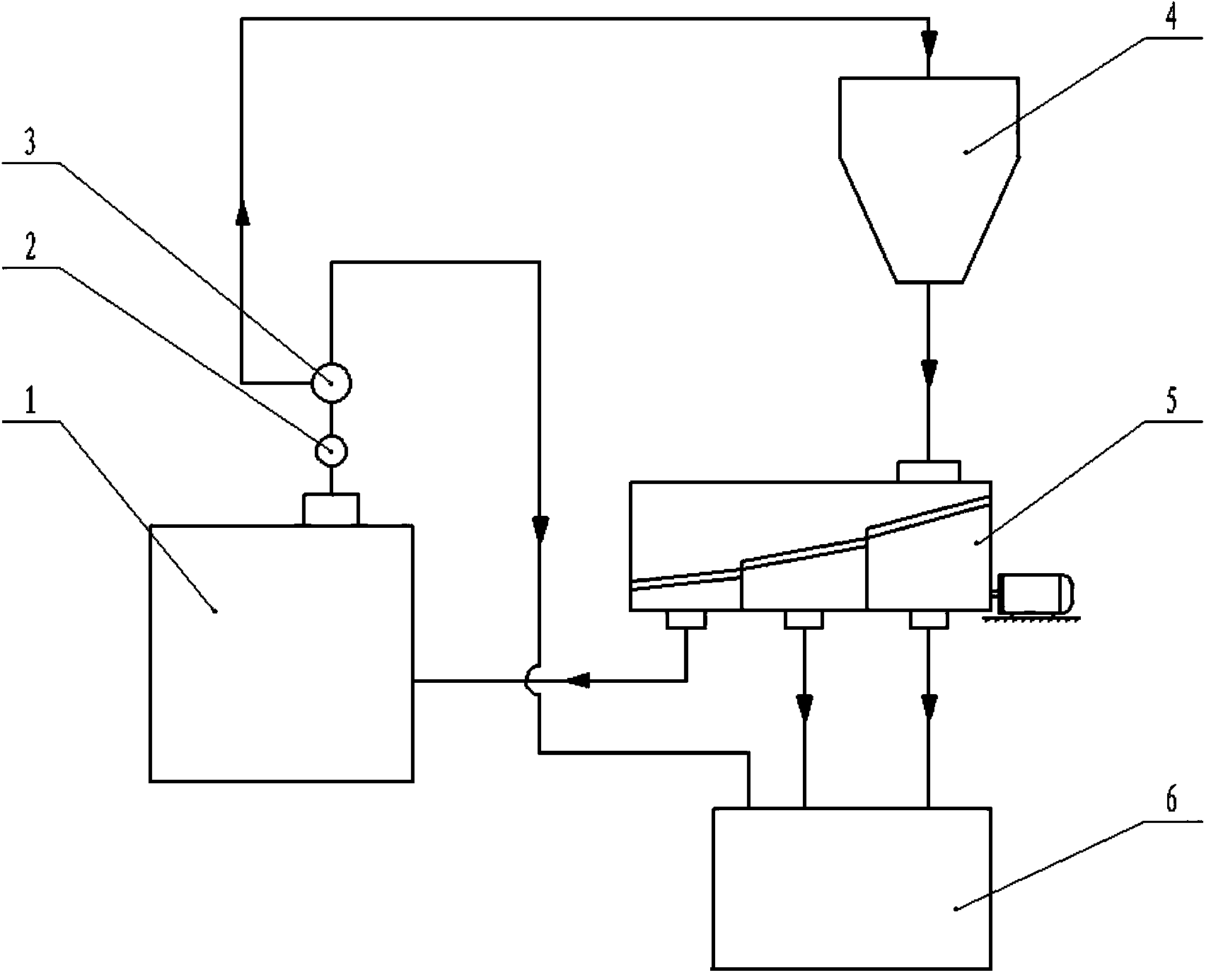

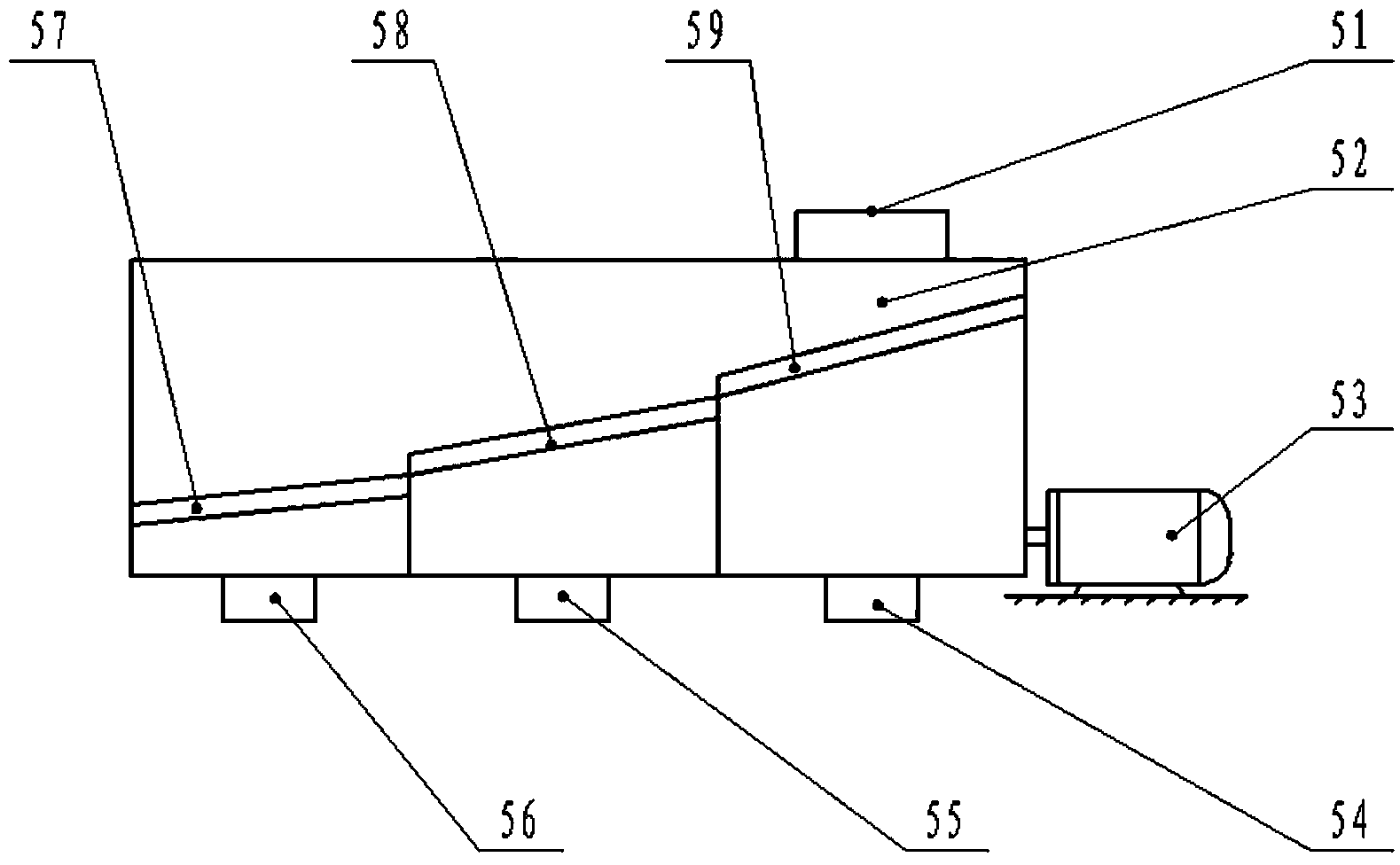

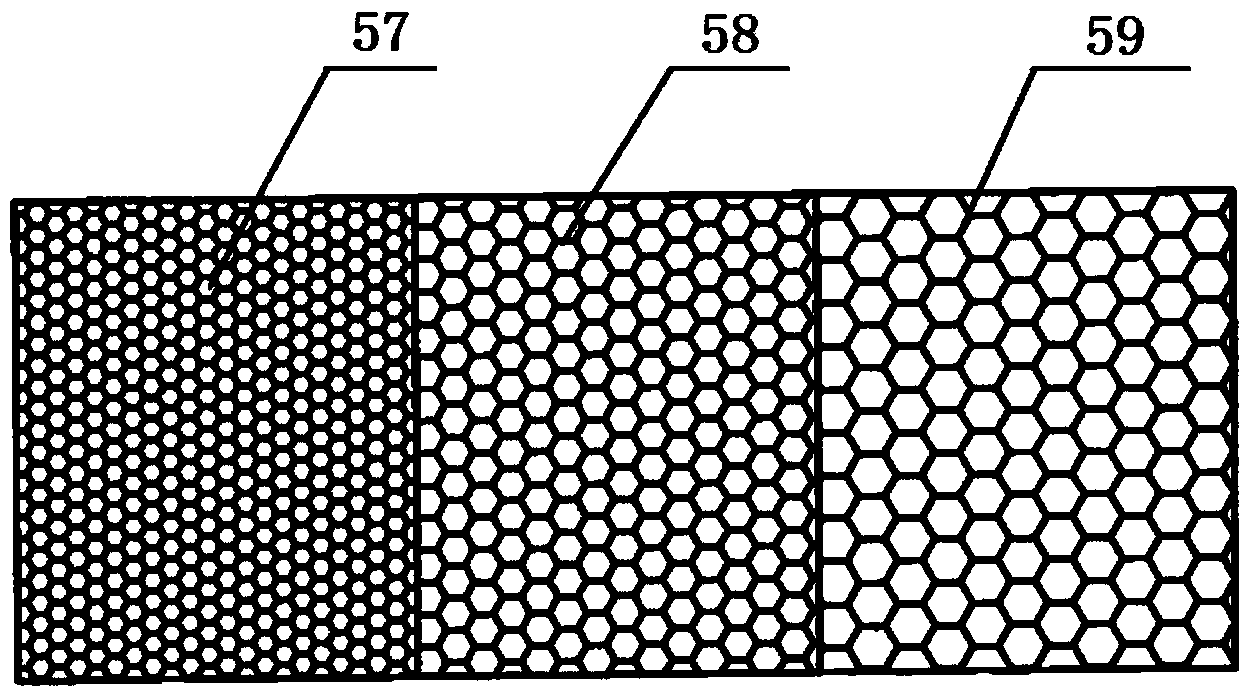

[0023] An electrolytic manganese dioxide screening equipment includes a grinding machine 1, a cyclone separator 4, a vibration screening machine 5 and a storage bin 6. An online analytical sampling instrument 2 is provided on the discharge port of the grinder 1, and a three-way valve 3 is provided above the online analytical sampling instrument 2, and the three-way valve 3 is a pneumatic three-way valve. One way of the three-way valve 3 is connected with the storage bin 6, the other way of the three-way valve 3 is connected with the inlet of the cyclone separator 4, and the outlet of the cyclone separator 4 is connected with the vibrating screening machine 5. The vibratory screening machine 5 includes a material inlet 51, a cabinet 52, a motor 53, a fine material outlet A54, a fine material outlet B55 and a coarse material outlet C56. There are three screens with different apertures inside the cabinet 52. The screens are inclined and connected into a ladder shape with increasi...

Embodiment 2

[0026] An electrolytic manganese dioxide screening equipment includes a grinding machine 1, a cyclone separator 4, a vibration screening machine 5 and a storage bin 6. An online analytical sampling instrument 2 is provided on the discharge port of the grinder 1, and a three-way valve 3 is provided above the online analytical sampling instrument 2, and the three-way valve 3 is an electric three-way valve. One way of the three-way valve 3 is connected with the storage bin 6, the other way of the three-way valve 3 is connected with the inlet of the cyclone separator 4, and the outlet of the cyclone separator 4 is connected with the vibrating screening machine 5. The vibratory screening machine 5 includes a material inlet 51, a cabinet 52, a motor 53, a fine material outlet A54, a fine material outlet B55 and a coarse material outlet C56. There are three screens with different apertures inside the cabinet 52. The screens are inclined and connected into a ladder shape with the aper...

Embodiment 3

[0029] An electrolytic manganese dioxide screening equipment includes a grinding machine 1, a cyclone separator 4, a vibration screening machine 5 and a storage bin 6. An online analytical sampling instrument 2 is provided on the discharge port of the grinder 1, and a three-way valve 3 is provided above the online analytical sampling instrument 2, and the three-way valve 3 is an electro-hydraulic three-way valve. One way of the three-way valve 3 is connected with the storage bin 6, the other way of the three-way valve 3 is connected with the inlet of the cyclone separator 4, and the outlet of the cyclone separator 4 is connected with the vibrating screening machine 5. The vibratory screening machine 5 includes a material inlet 51, a cabinet 52, a motor 53, a fine material outlet A54, a fine material outlet B55 and a coarse material outlet C56. There are three screens with different apertures in the cabinet 52. The screens are inclined and connected into a ladder shape with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com