Closed loop balance wheel pulse sand making machine and sand making method

A pulse system and closed-loop technology, which is applied in the field of crushing machinery, can solve the problems of large wear and consumption of crushing working parts, long stone turnover and production lines, and low sand making efficiency of the system, so as to achieve high-efficiency sand discharge of finished products and low production and operation costs. , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

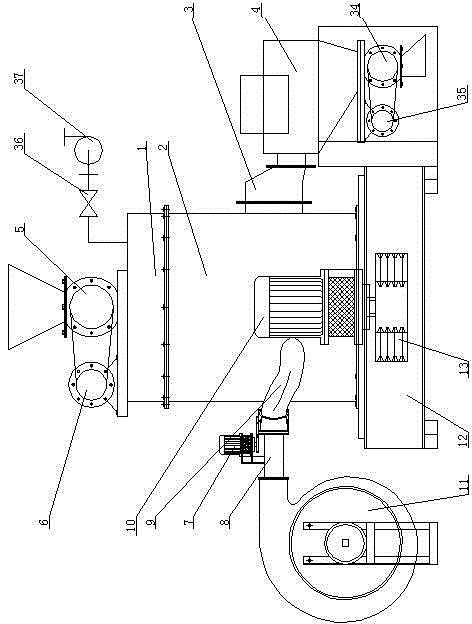

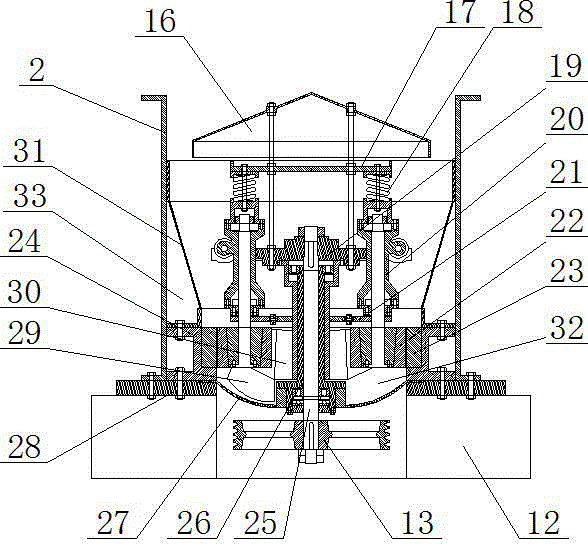

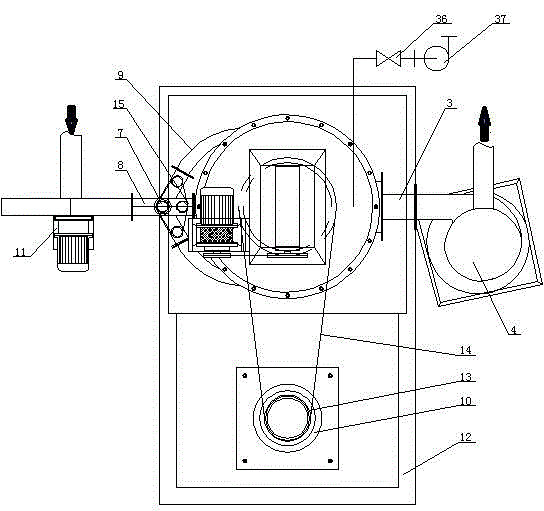

[0036]The closed-circuit balance wheel pulse sand making machine shown in the figure includes machine cover 1, main machine casing 2, discharge hopper 3, cyclone separator 4, closed air feeder 5, feeder motor 6, pulse fan motor 7 , pulse fan 8, side air duct 9, spindle motor 10, blower 11, base 12, pulley 13, belt 14, straight air duct 15, material guide 16, pressure support frame 17, roller spring 18, suspension roller Support frame 19, suspension roller device 20, grinding roller limiting device 21, grinding roller 22, grinding ring 23, grinding ring seat 24, main shaft 25, main shaft seat 26, bottom screen 27, host mounting plate 28, shovel scraper 29, Shovel rest 30, screen mesh cylinder 31, grinding bin 32, side product collection bin 33, wind-off discharger 34, discharger motor 35, valve 36 and water pump 37.

[0037] The wind-closing feeder 5 and the feeder mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com