A precision grinding device and parameter determination method for plane local high point removal

A local high point and grinding device technology, which is applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve problems affecting the plane accuracy of workpieces, achieve high grinding accuracy, reduce non-uniform wear, and have good market application prospects and The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

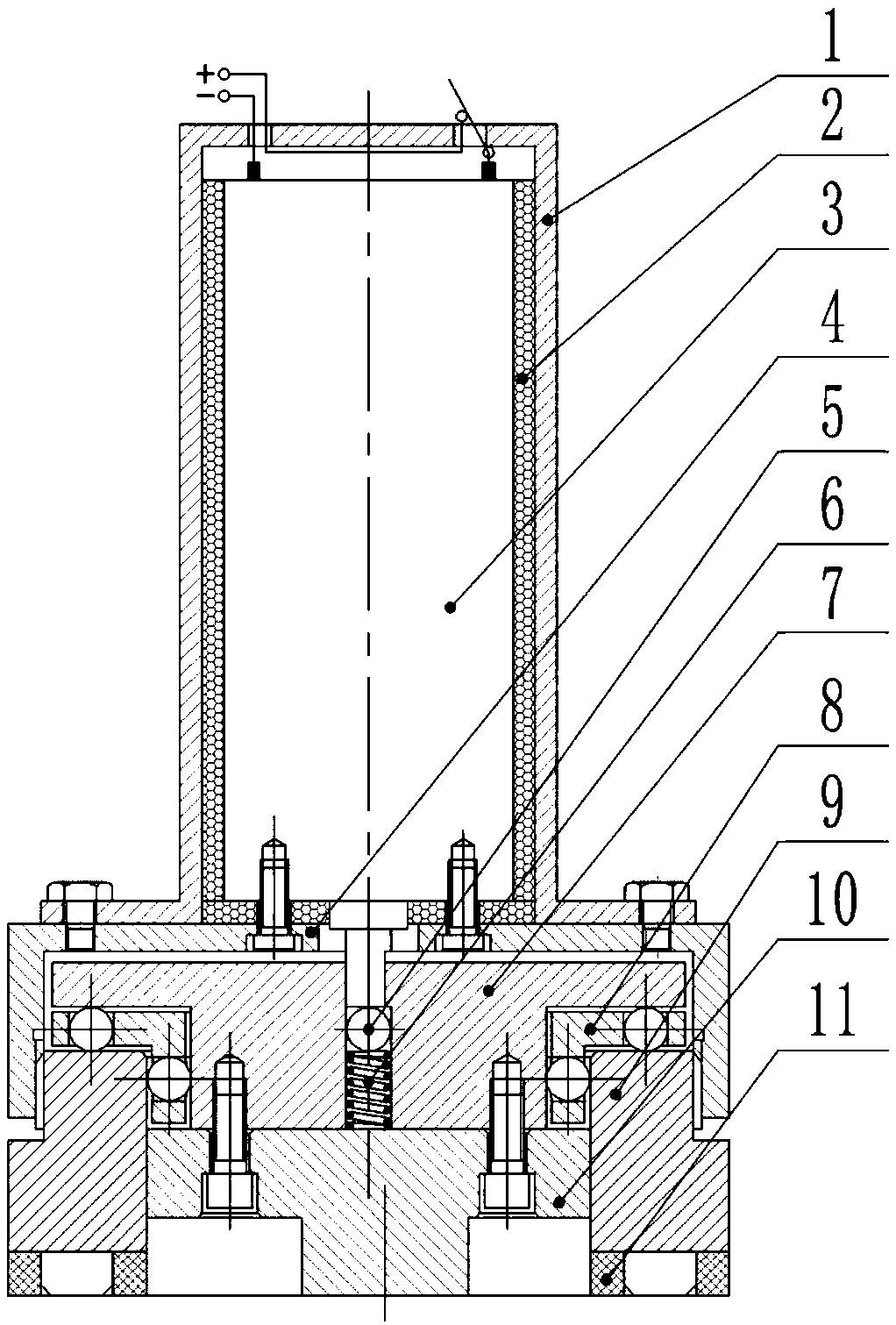

[0025] (1) Assembly of a precision grinding device for plane local high point removal

[0026] First ensure that the height of the two ends of the reference block is equal to the height of the working surface of the eccentric grinding block and the shoulder end face of the large cylindrical end of the connecting block minus the diameter of the axial spherical rolling body of the dense bead bushing; by grinding the two ends of the reference block 9, the transfer block 7 or the two end faces of the eccentric grinding block 10 to meet the above requirements;

[0027] Then determine the height of the stage clip 6 to ensure that the stage clip produces a pressure of 1 to 2 kg in the working process, and control the working pressure of the stage clip by adjusting the depth at which the connecting shell 4 is screwed into the reference block. The assembly steps of the device are as follows:

[0028] (1) Assemble the geared motor 3, housing 1 and connection housing 4 together.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com