Valve seat grinding, clamping and moving device

A technology for moving devices and valve seats, which is applied in the direction of grinding drive devices, seat surface grinders, grinding machines, etc. It can solve the problems of reduced processing efficiency, difficulty in adjusting the pressure of the valve seat and the ball core, and adjusting the grinding effect of the valve seat and the ball core, etc. , to achieve the effect of reducing workload and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

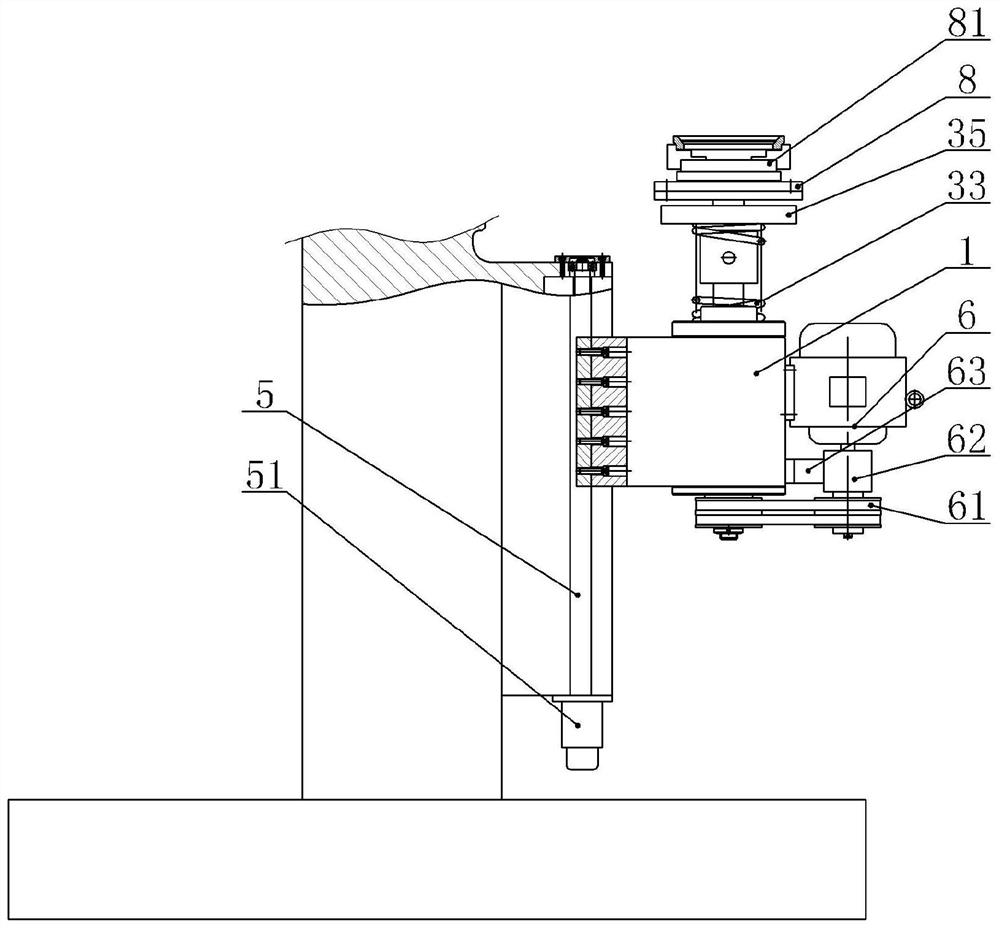

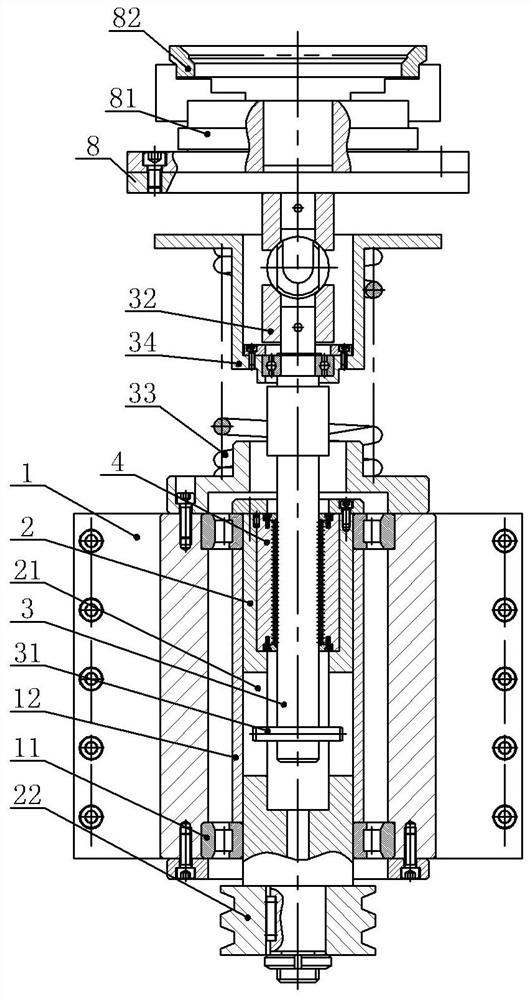

[0039] Seat lapping clamping mobile device, such as figure 1 , figure 2As shown, it includes the bed, the valve seat clamping mechanism and the valve seat clamping movement mechanism. The valve seat clamping mechanism includes the transmission spindle 2, the transmission shaft 3, the clamping mechanism base 1 and the spring 33, the transmission shaft 3 and the transmission spindle 2 are arranged vertically, the transmission spindle 2 vertically runs through the clamping mechanism base 1 and is coaxial with the clamping mechanism base 1, and a bearing positioning sleeve 12 and two Rolling bearings, the two rolling bearings are located at both ends of the bearing positioning sleeve 12, specifically, the rolling bearings in this embodiment use cylindrical roller bearings 11, the bearing positioning sleeve 12 uses cylindrical roller bearing positioning sleeves, cylindrical roller bearings and cylindrical roller bearings The installation methods of the sub-positioning sleeves are...

Embodiment 2

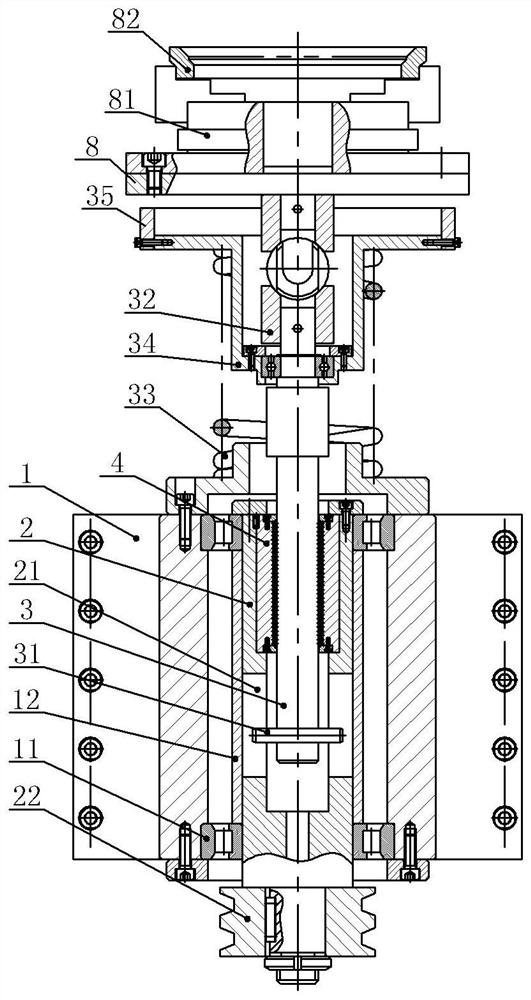

[0054] On the basis of Example 1, such as image 3 As shown, a stopper 35 is provided below the self-centering chuck 81 in this embodiment. The stopper 35 in this embodiment is an annular stop ring, and the inner wall of the stop ring is in contact with the upper end of the spring seat 34. Paste and fix with the spring seat 34 by bolts, so that the limit ring can rotate with the transmission shaft 3.

[0055] During the use of the device in this embodiment, when the chuck seat 8 tilts under the valve seat 82 or its own gravity, it can be blocked by the stopper 35. The inclination angle of the chuck 81 acts as a limiter, so as to avoid that the inclination angle is too large to make it difficult to fix the valve seat 82 or make it difficult for the center of the valve seat 82 to coincide with the center of the ball core, resulting in failure to match and grind.

Embodiment 3

[0057] On the basis of Example 2, such as Figure 4 As shown, this embodiment includes two valve seat clamping mechanisms and two valve seat clamping moving mechanisms, and the two valve seat clamping mechanisms are arranged symmetrically up and down along the horizontal plane, and the two valve seat clamping moving mechanisms are arranged up and down along the same horizontal plane Symmetrical setting. In this embodiment, two self-centering chucks 81 are included, so two valve seats 82 can be fixed at one time, so that the two valve seats 82 can be ground, and the grinding efficiency can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com