Patents

Literature

60results about How to "No manual movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Argon arc welding machine with heat dissipation function and working method thereof

ActiveCN110405325APrecise positioningProtectiveWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingSlide plate

The invention discloses an argon arc welding machine with a heat dissipation function and a working method thereof. The argon arc welding machine comprises an operating platform, a fixing plate, a support and a welding gun, wherein a second cylinder is fixedly arranged at the center of one side of the fixing plate, and an ejector rod is fixedly arranged on a piston rod of the second cylinder. Theejector rod is driven by the second cylinder to push two movable plates to move towards the middle, a pipe fitting is fixed by two clamps, the pipe fitting can be loosened instead, the pipe fitting isconvenient to fix and loosen, manual fixing is avoided, loosening is easy, labor intensity can be reduced, and working efficiency is improved; a first cylinder drives an air cylinder telescopic rod to push a sliding plate to move rightwards, so that the pipe fitting is pushed to slide rightwards, and the pipe fitting can be roughly adjusted in a large range; the sliding plate is driven by a second lead screw to push the pipe fitting to slide rightwards, accurate adjustment in a small range can be carried out, the pipe fitting can be positioned more accurately, deviation in positioning cannotoccur, welding is easy, and operation is convenient.

Owner:SHENZHEN SOLGOO TECH

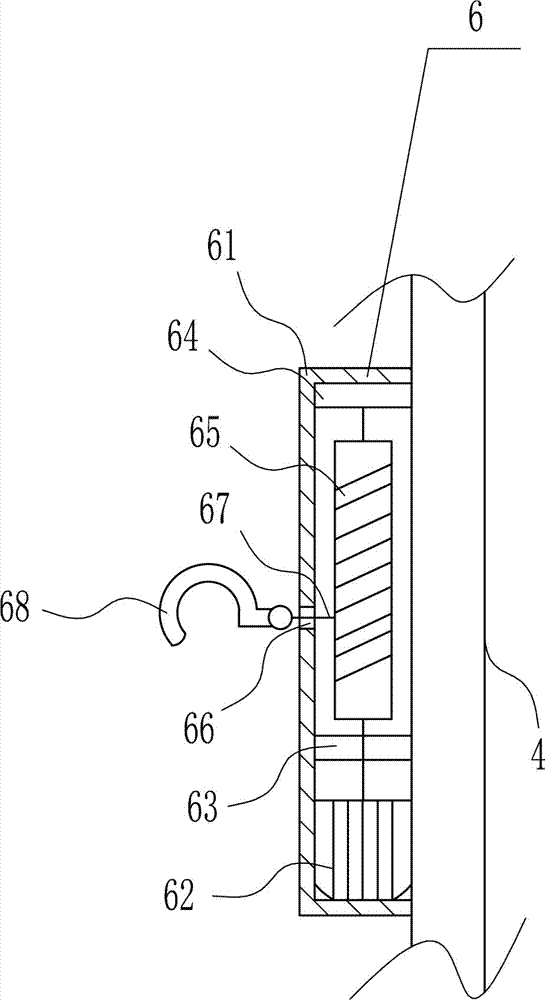

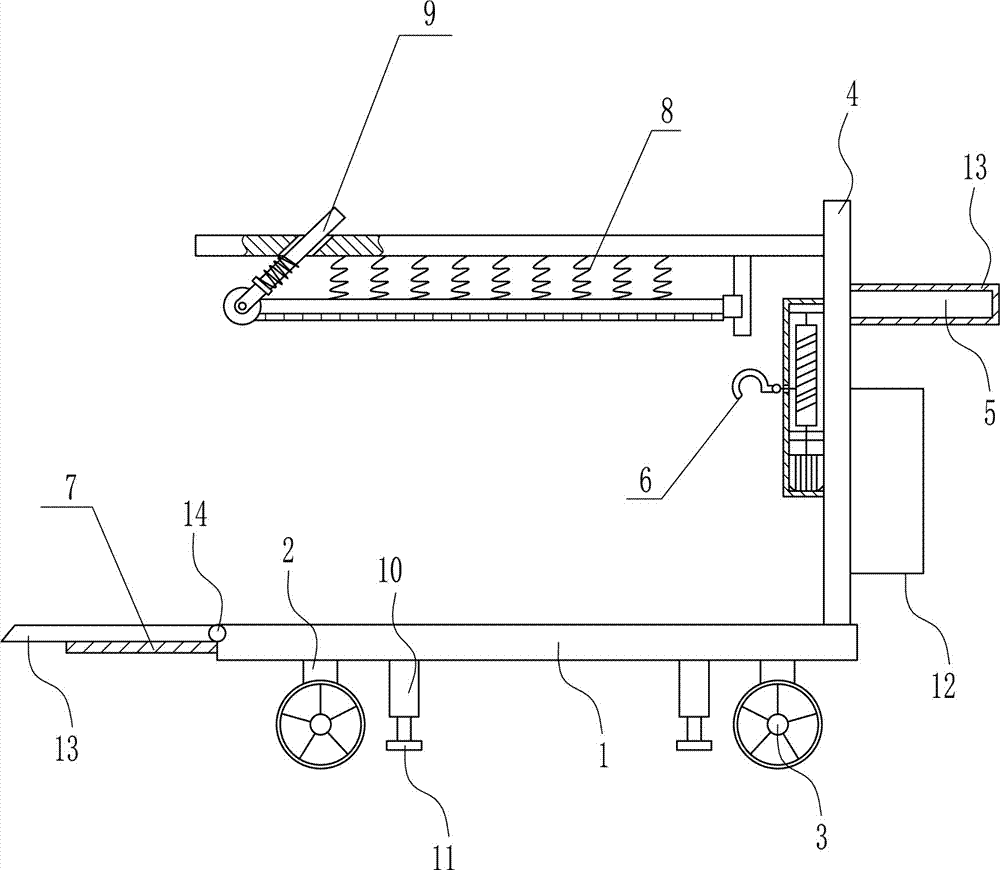

Small sewage treatment equipment carrying device for hospital

InactiveCN106945701ANo manual movementWon't fallSupporting partsHand carts with multiple axesSewage treatmentBolt connection

The invention relates to a sewage treatment equipment carrying device, in particular to a small sewage treatment equipment carrying device for a hospital. By adoption of the small sewage treatment equipment carrying device for the hospital, no much manpower is needed, sewage treatment equipment can be more conveniently transported, and therefore sewage treatment equipment is not prone to being damaged. The small sewage treatment equipment carrying device for the hospital comprises a base plate, vertical rods, wheels, a supporting plate, a handle, a traction device, a fixing device and the like. The bottom of the base plate is provided with the vertical rods. The bottom ends of the vertical rods are provided with the wheels in a bolt connection mode. The left side of the base plate is provided with the fixing device. According to the small sewage treatment equipment carrying device, through contact rolling between contact rollers and the sewage treatment equipment, the sewage treatment equipment can more smoothly move, and therefore due to the effect of second springs, a transverse plate can better fix the sewage treatment equipment.

Owner:苏先强

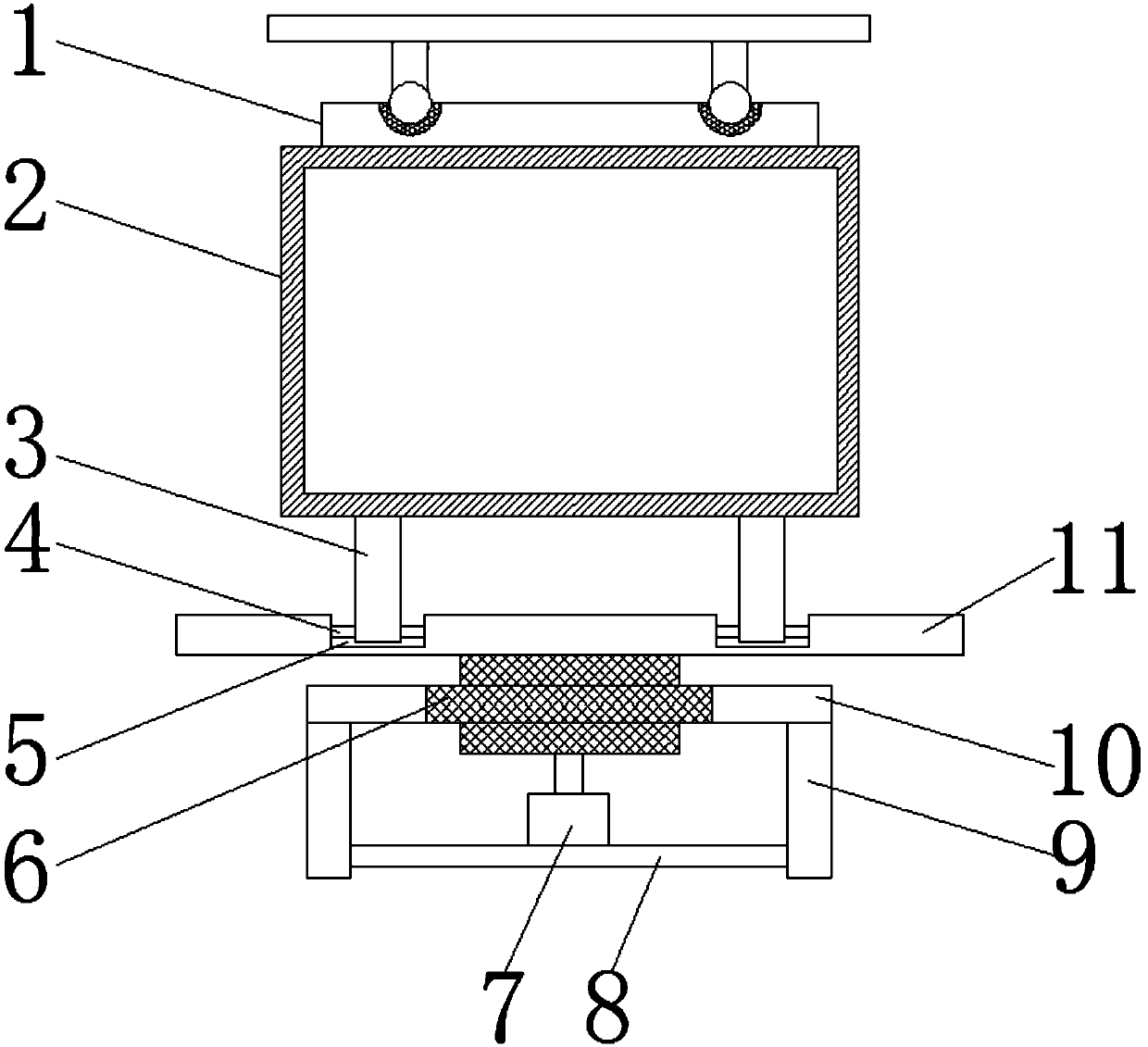

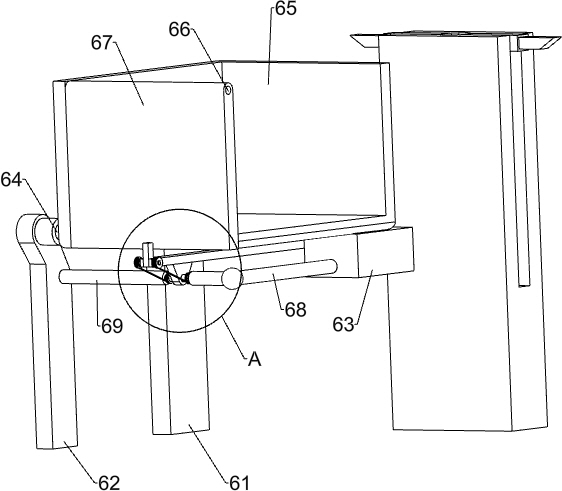

Angle adjusting device for display

InactiveCN109945042AGuaranteed normal useImprove practicalityStands/trestlesEngineeringDisplay device

Owner:邓伟

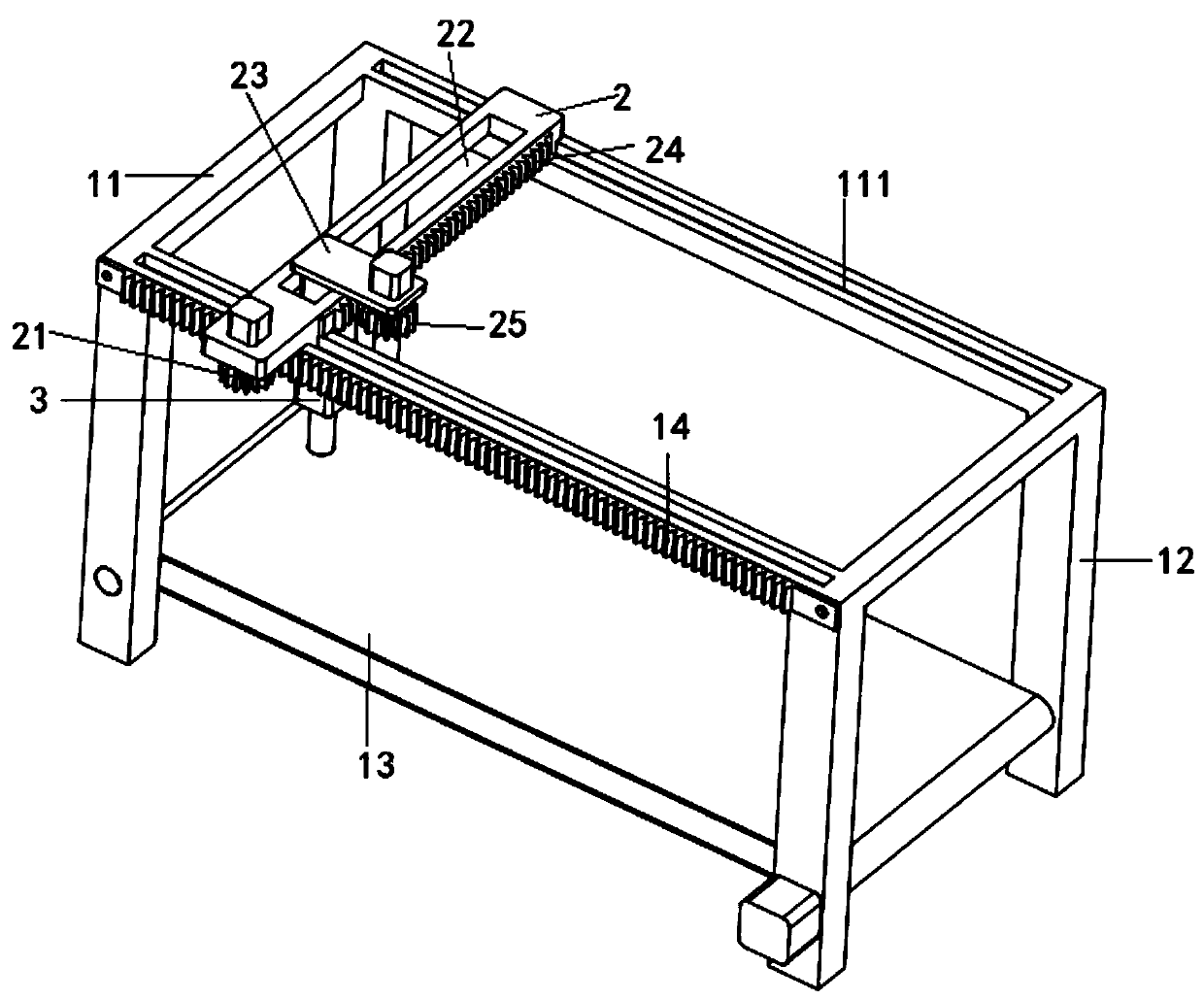

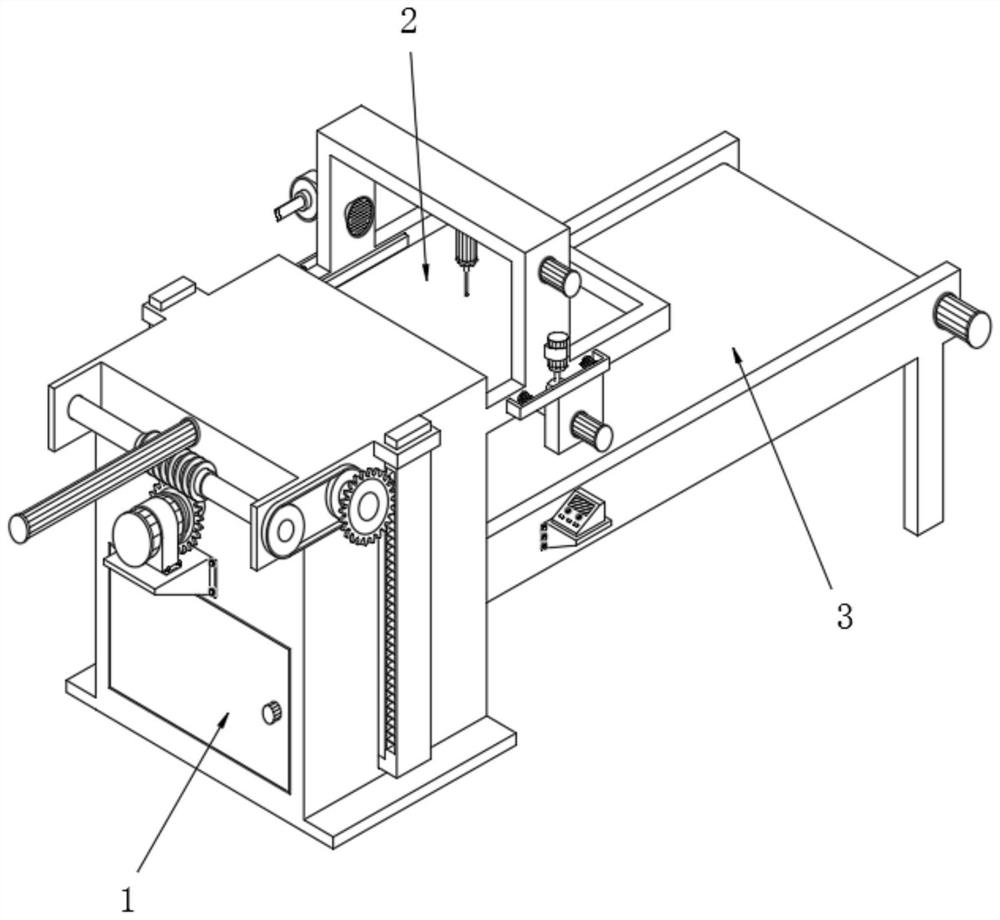

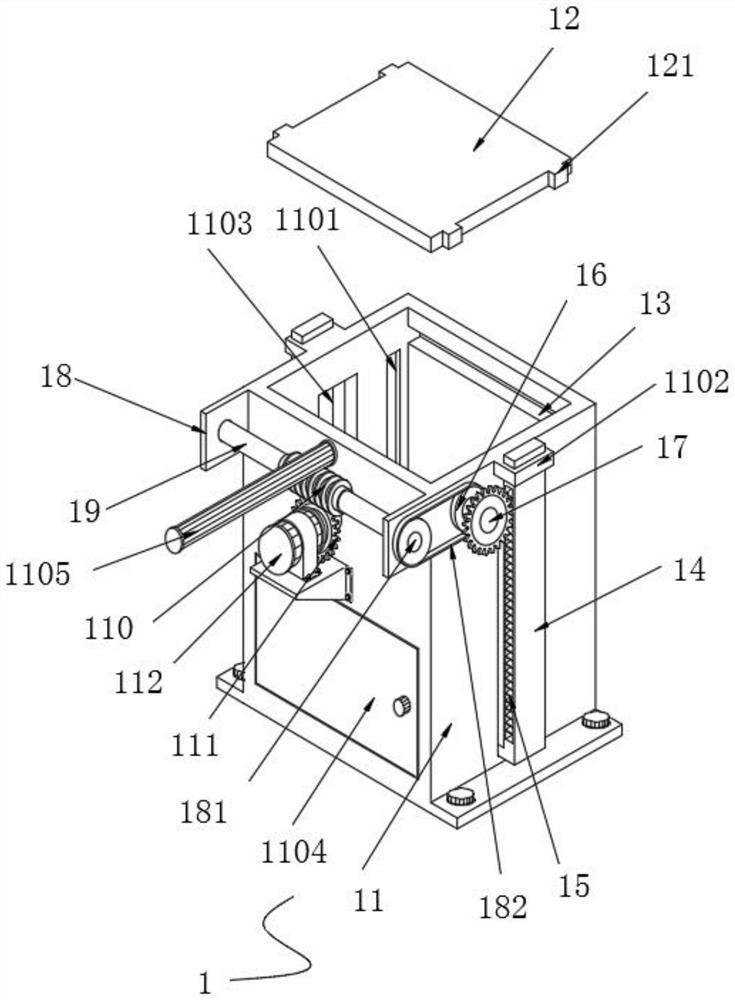

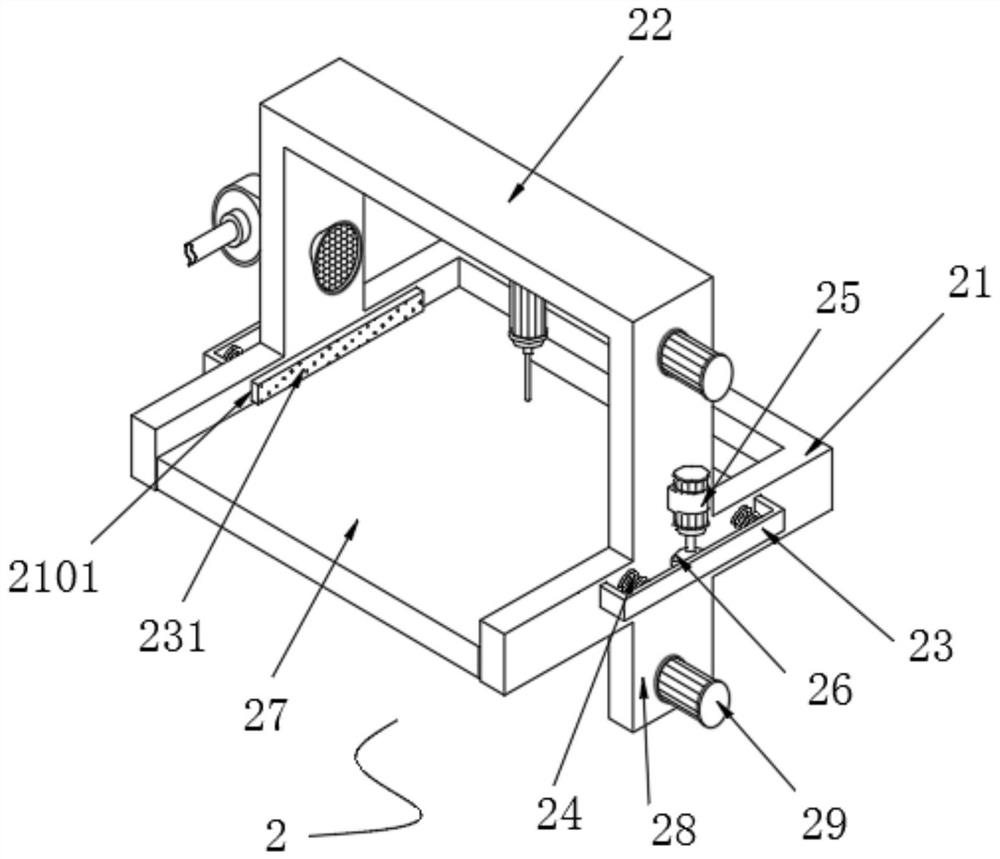

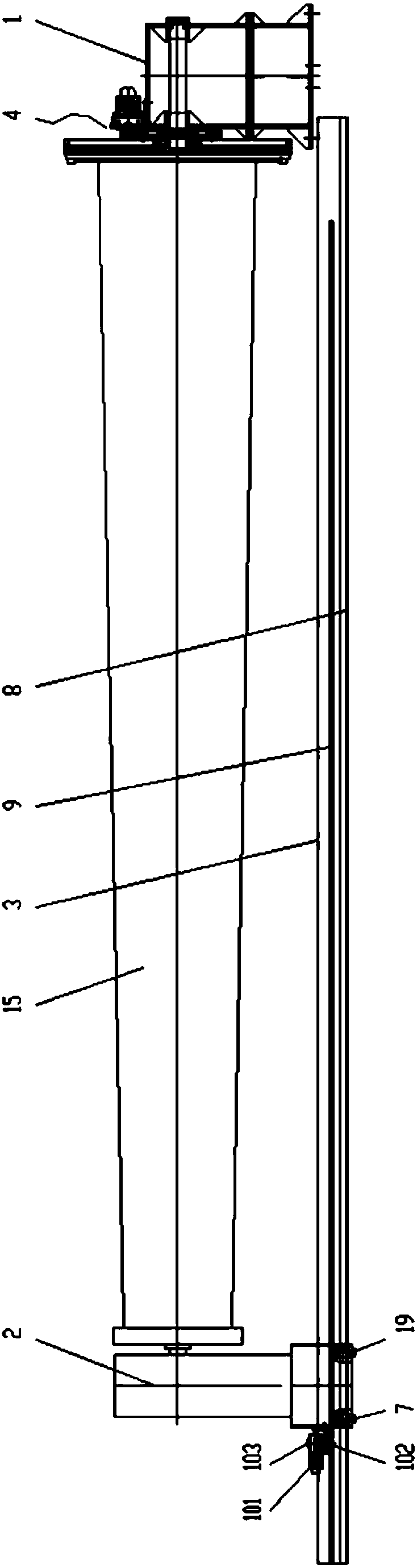

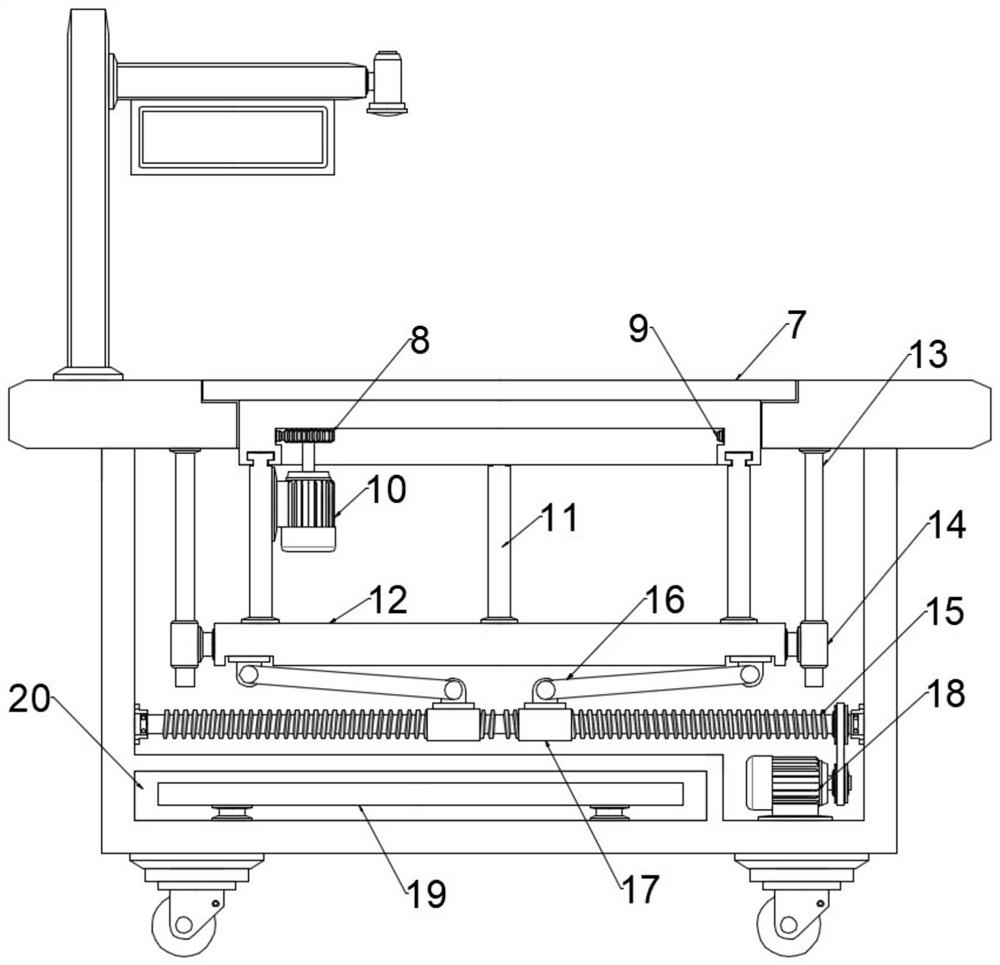

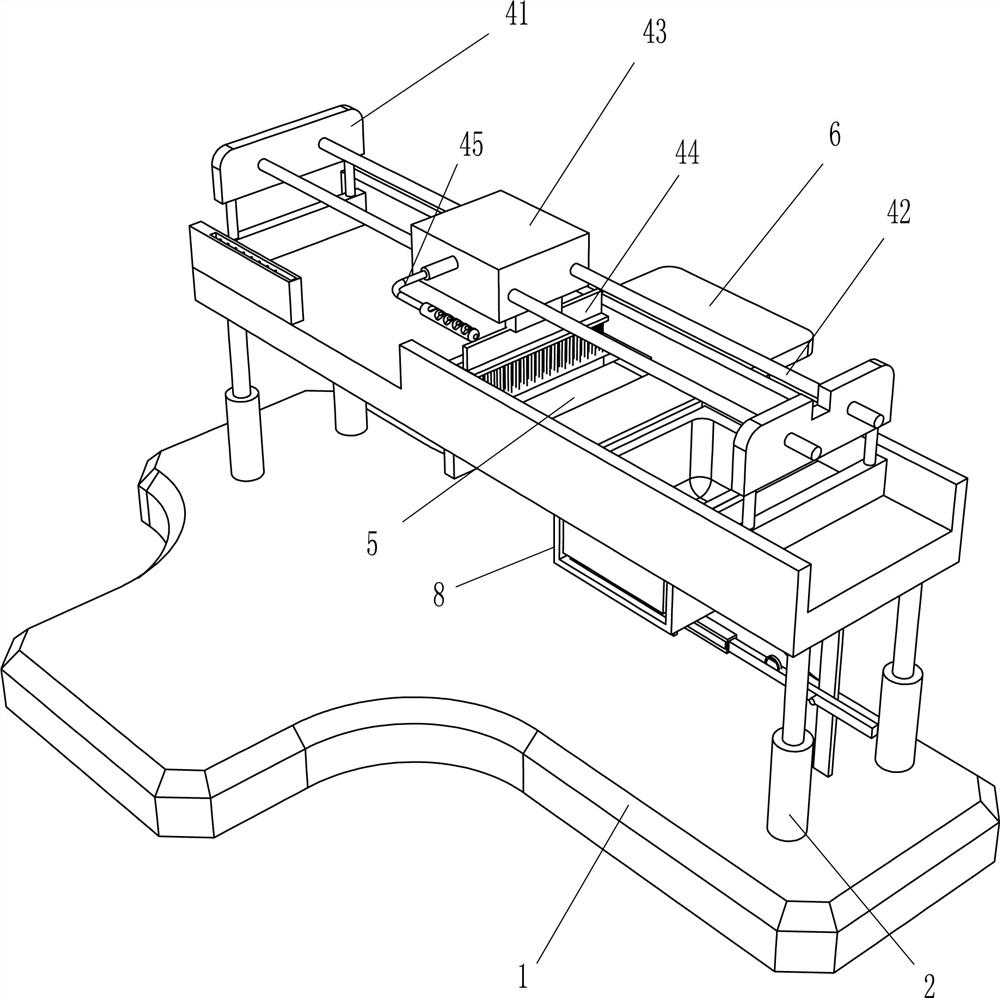

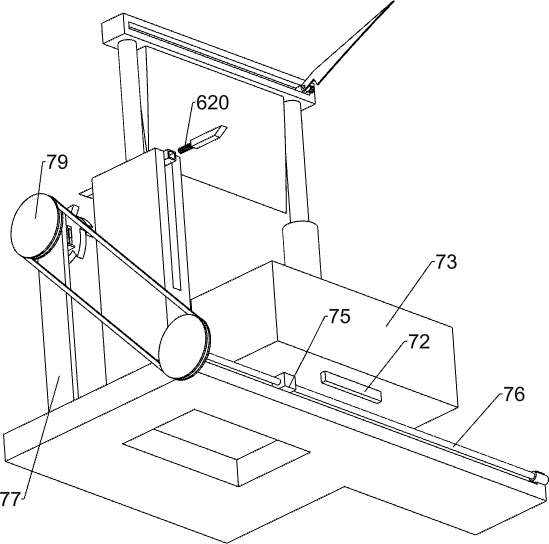

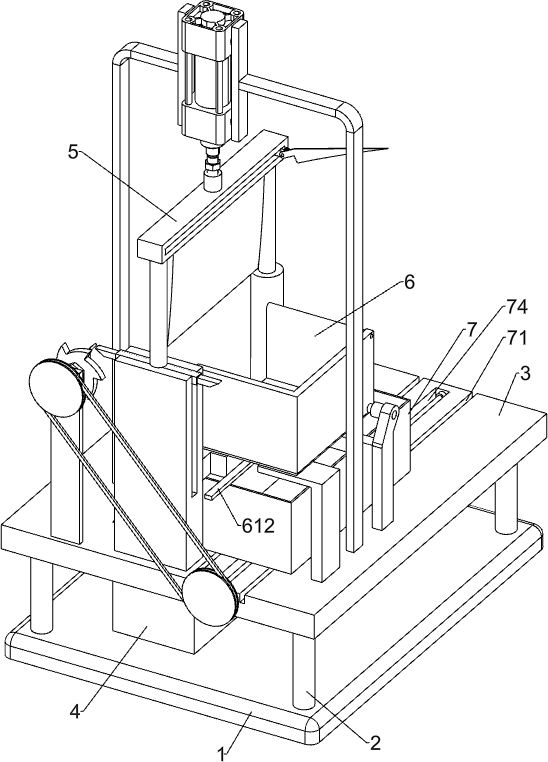

Adjustable aluminum alloy steel plate surface drilling equipment

ActiveCN111014770AImprove drilling efficiencyPrecise Drilling RequirementsBoring/drilling componentsBoring/drilling machinesPhysicsSteel plates

The invention discloses adjustable aluminum alloy steel plate surface drilling equipment. The equipment comprises a transmission positioning frame, wherein a fixed batten is slidably installed on a top end face of the transmission positioning frame, a first hydraulic cylinder is slidably installed on a surface of the fixed batten, and a synchronous drilling mechanism is installed at a power outputend of the first hydraulic cylinder. The drilling equipment is advantaged in that three hole sites can be drilled at the matching site of each steel plate at the same time, drilling efficiency is improved, and problems that in order to achieve firm connection and combination in the existing steel plate machining process, three or four hole sites are generally drilled at each matching site of thesteel plate, the matching strength between the steel plate and other plates is improved, and drilling efficiency is reduced due to the fact that drilling is generally conducted one hole site by one hole site in the existing numerical control equipment drilling process are solved.

Owner:灵璧县浩翔信息科技有限公司

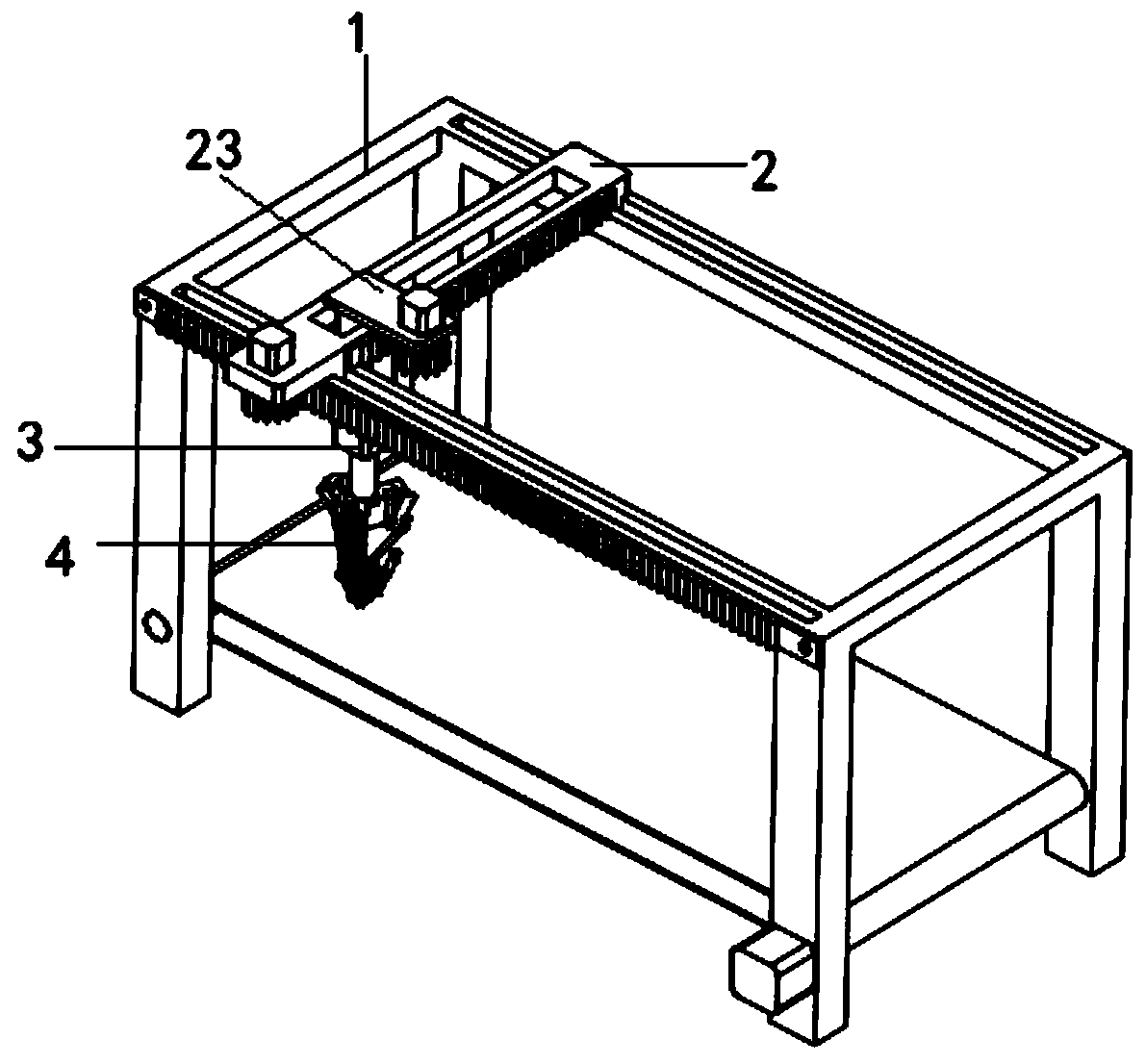

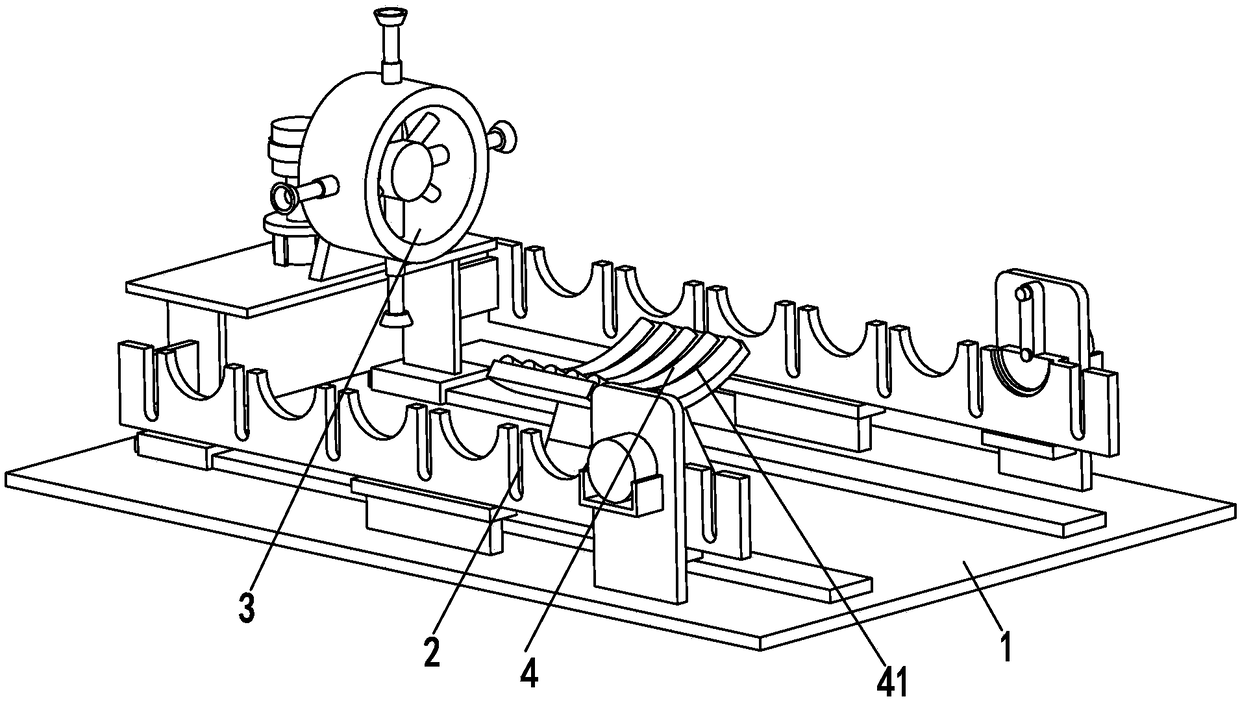

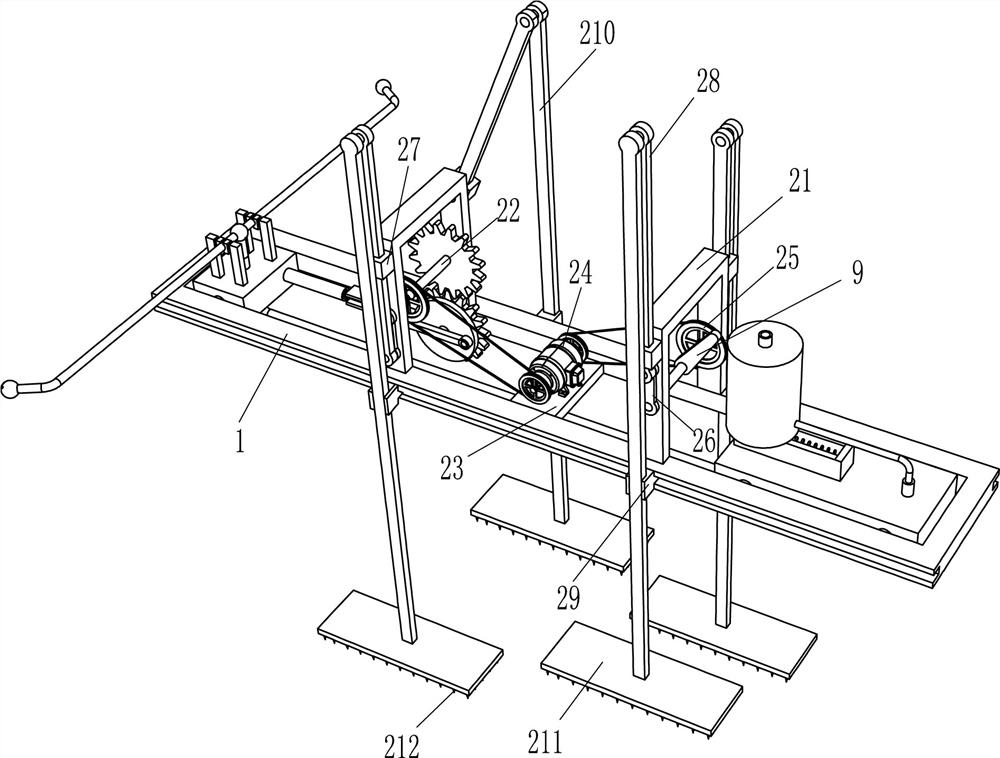

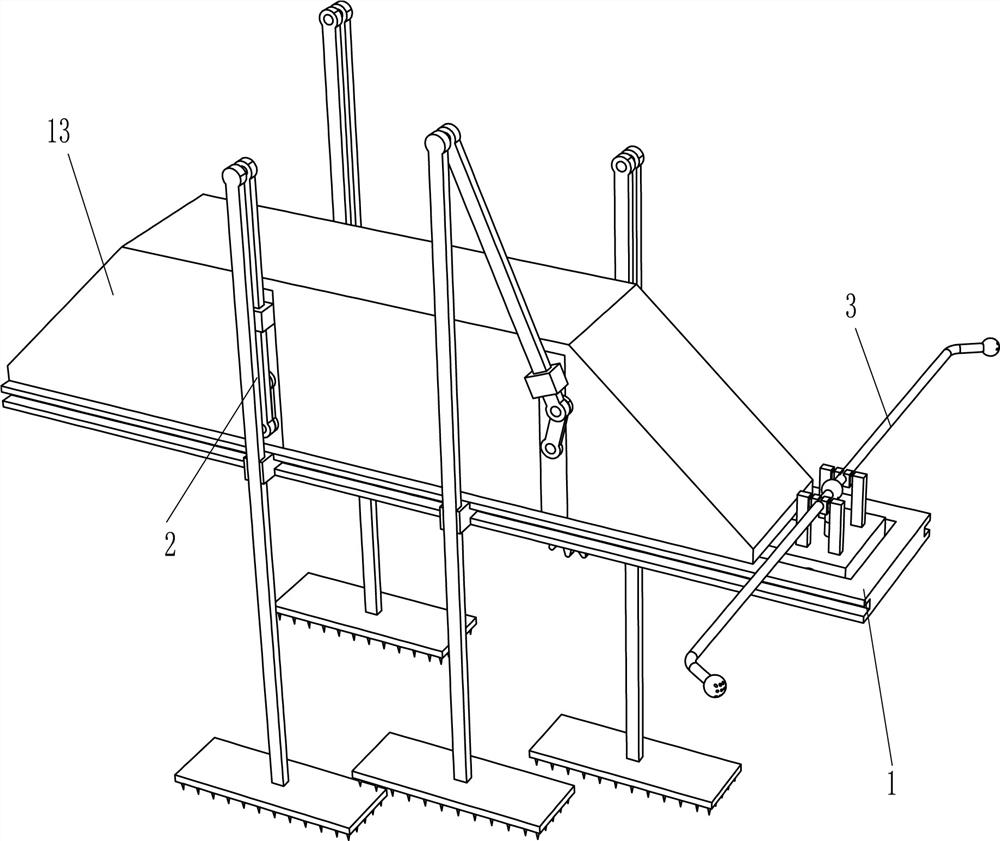

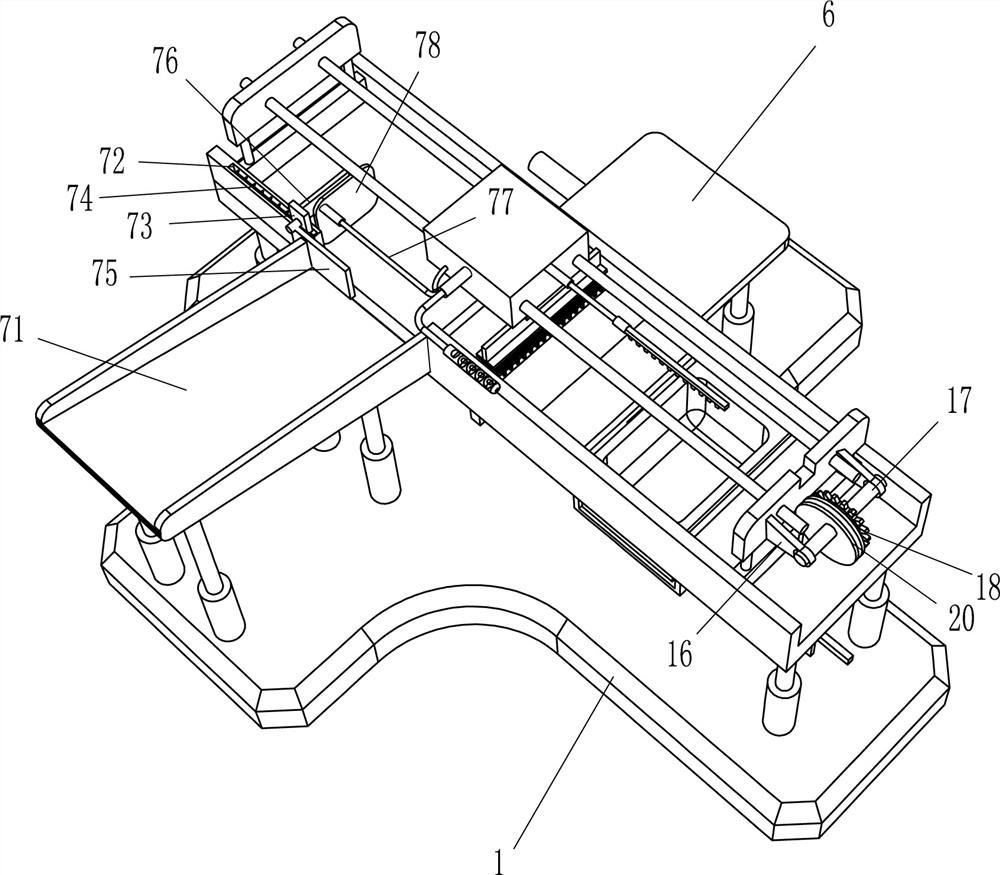

Watering device for broccoli planting

PendingCN112956401AEasy to use and labor-savingSave waterClimate change adaptationWatering devicesHorticultureFertilizer

The invention provides a watering device for broccoli planting. The watering device for broccoli planting comprises a main frame, wherein a driving mechanism is mounted on the main frame, an adjusting mechanism is mounted at the bottom of the driving mechanism, and a watering mechanism is mounted at the bottom of the adjusting mechanism; the driving mechanism is used for driving the adjusting mechanism and the watering mechanism to reciprocate on the main frame, the adjusting mechanism is used for adjusting the vertical height of the watering mechanism, and the watering mechanism is used for watering broccoli. The watering device for broccoli planting has a walking function, does not need to be manually moved, is convenient and labor-saving to use, waters broccoli in a spraying mode, not only facilitates sufficient water absorption of the surface of the broccoli, but also saves water, effectively saves water resources, can be used as a sprayer, and can be used for spraying pesticides and foliar fertilizers; the device is good in practicability, the whole device is of an arch structure, the device is particularly suitable for being placed in a plastic greenhouse, great convenience is brought to daily vegetable growing work of vegetable farmers, and the daily work load of the vegetable farmers is effectively reduced.

Owner:TAIZHOU UNIV

Shell body paint spraying equipment for power distribution cabinet

ActiveCN113385348AImprove painting efficiencyAvoid affecting the quality of paintingPretreated surfacesCleaning using gasesCamStructural engineering

The invention discloses shell body paint spraying equipment for a power distribution cabinet. The shell body paint spraying equipment for the power distribution cabinet comprises a cabinet body, a processing mechanism for carrying out cleaning and drying on the side wall of the power distribution cabinet is arranged on the cabinet body, the processing mechanism comprises two grooves formed in the bottom of the cabinet body, the inner walls of the two grooves are slidably connected with two supporting plates, a drying frame and a cleaning frame are fixedly connected to the upper ends of the two supporting plates respectively, the side walls of the supporting plates are elastically connected with the inner walls of the grooves through springs, a servo motor is fixedly connected to the bottom of the cabinet body, a first one-way bearing is fixedly connected to the side wall of a movable shaft of the servo motor, and two cams are fixedly connected to an outer ring of the first one-way bearing. According to the shell body paint spraying equipment for the power distribution cabinet, the processing mechanism and an air pumping mechanism are arranged, when the drying frame and the cleaning frame are attached to the side wall of the power distribution cabinet respectively, hot air and cold air generated in a vortex tube enter the drying frame and the cleaning frame respectively, then synchronous drying and cleaning can be carried out when paint spraying is carried out on the surface of the power distribution cabinet, and then the paint spraying efficiency is improved.

Owner:南通索星流体设备有限公司

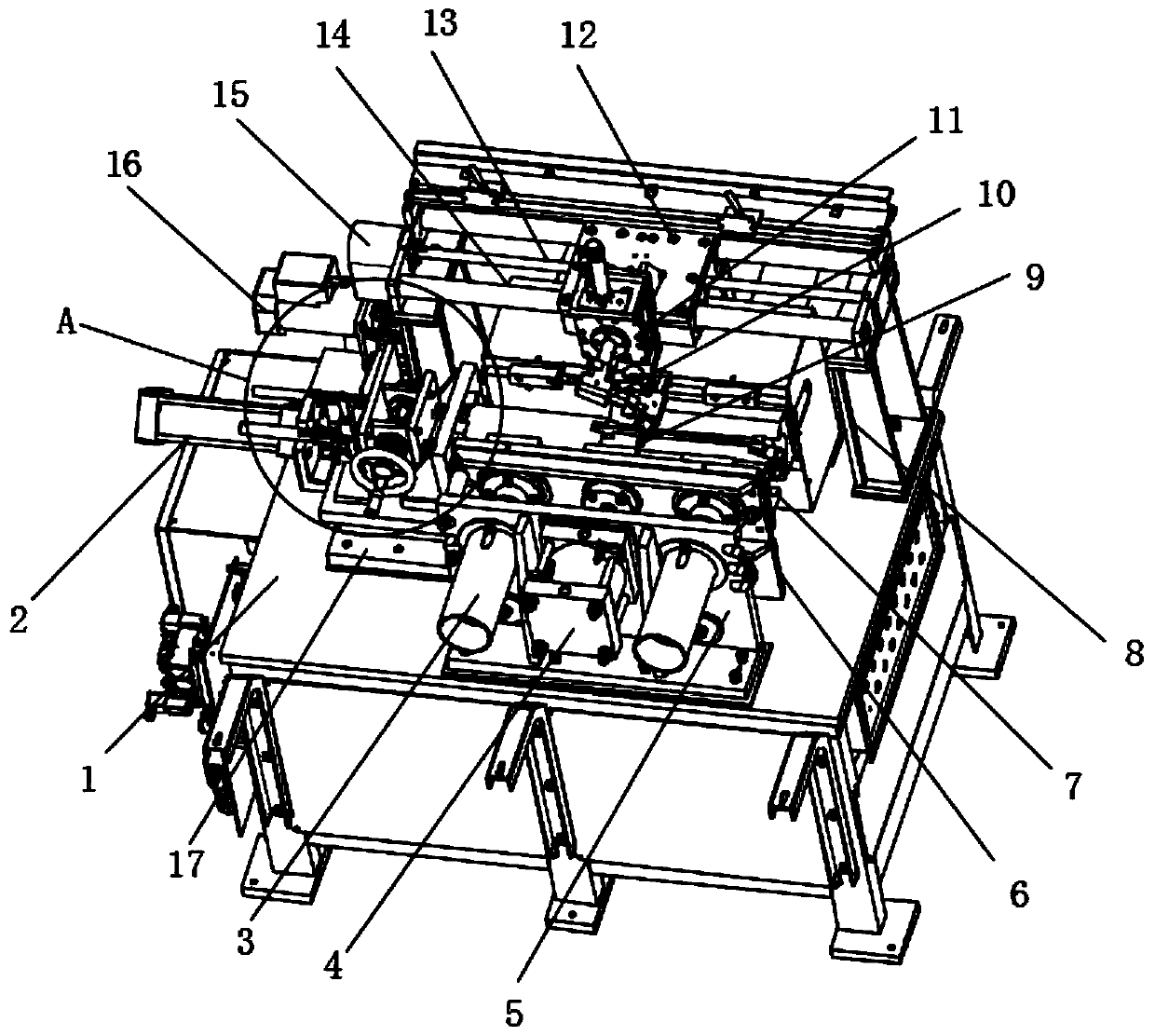

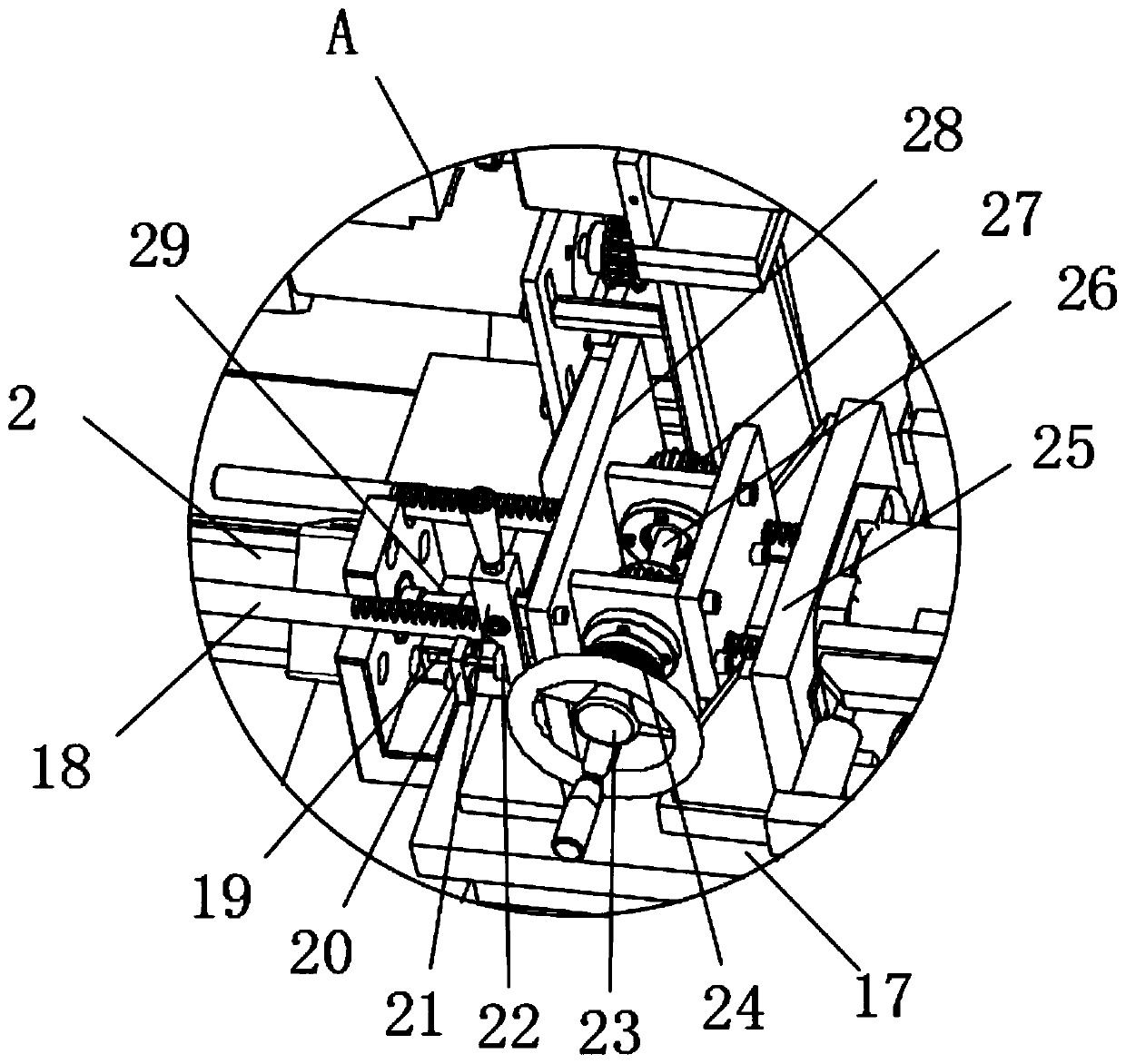

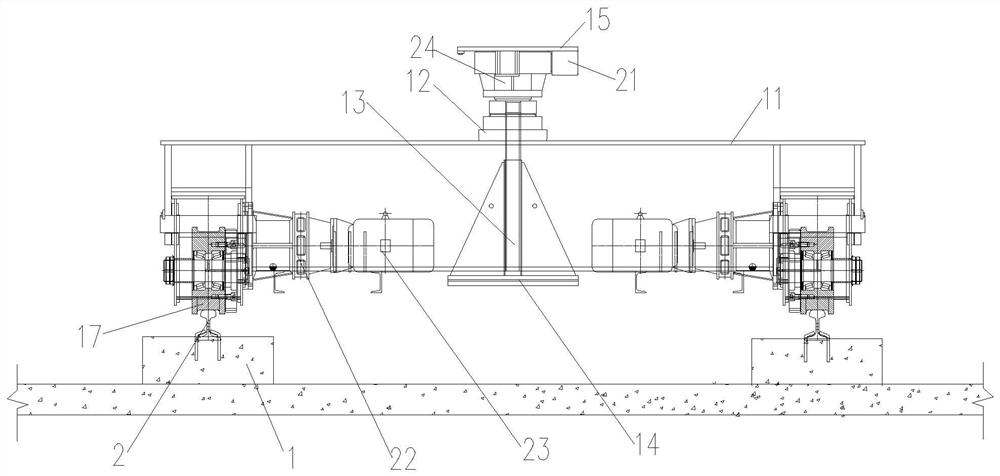

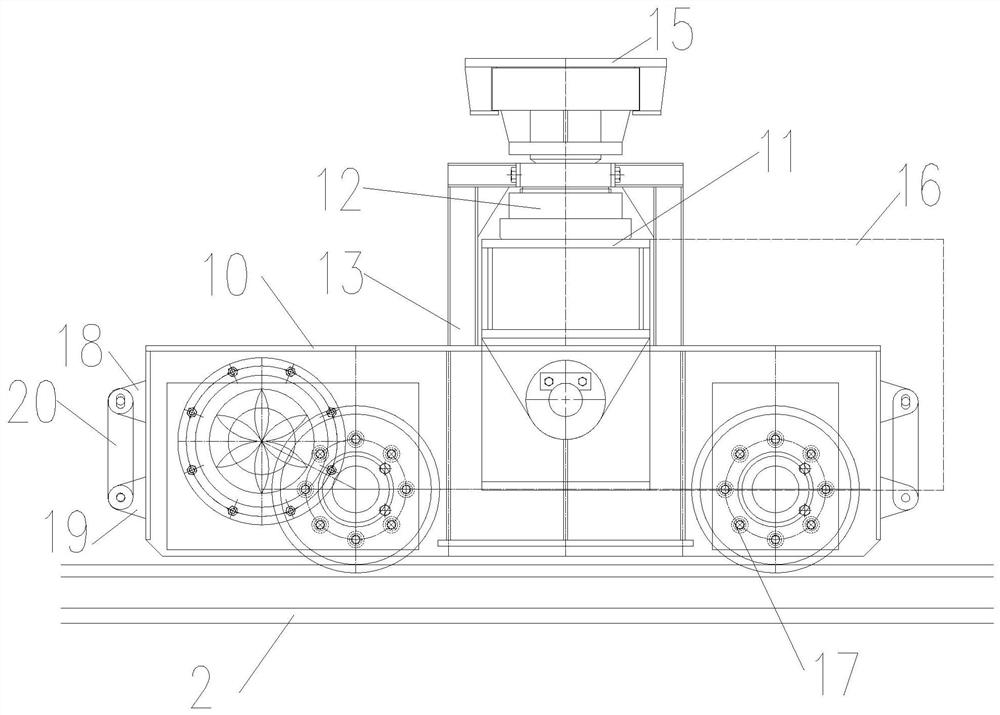

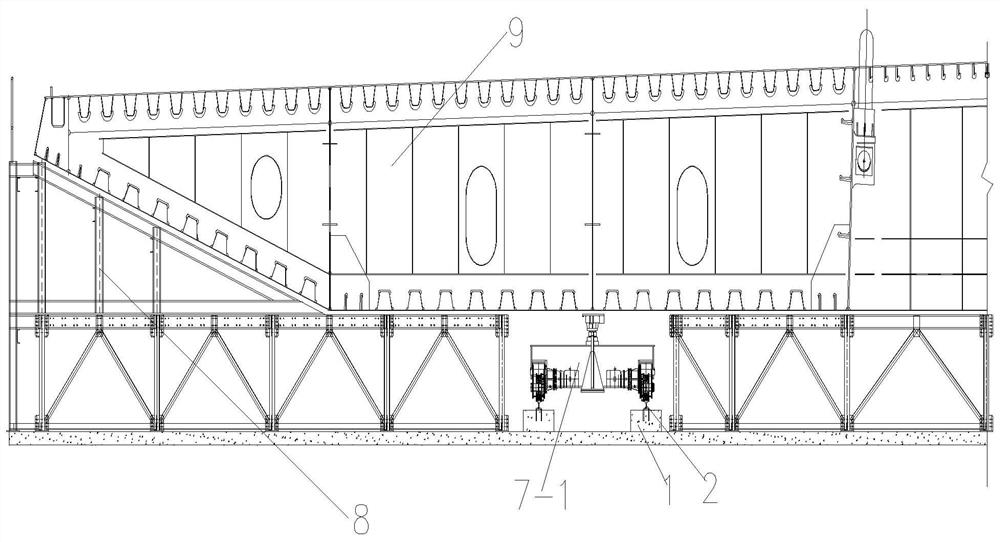

Girder transporting vehicle, girder transporting system, steel box girder assembling system and steel box girder assembling methods

ActiveCN112323644AHigh precisionAvoid damageBridge erection/assemblyBridge materialsArchitectural engineeringJackscrew

The invention discloses a girder transporting vehicle which comprises two carriages, a balance box girder, a girder transporting vehicle main jack and a girder transporting vehicle auxiliary jack. Theinvention further discloses a girder transporting system. The girder transporting system comprises the girder transporting vehicle, a swing mechanism and a rail clamping mechanism. The invention further discloses a steel box girder assembling system which comprises the girder transporting system and a crane system. The invention further discloses a steel box girder assembling method. The method comprises the steps of 1 conveying a steel box girder in place; 2 lowering a lifting appliance to be connected with the steel box girder; 3 lifting the steel box girder, and adjusting the position of the steel box girder three-dimensionally; 4 adjusting the gradient of the steel box girder; 5 assembling the steel box girder; 6 moving a base forwards to the updated assembling end of the steel box girder; and 7 finishing the assembly of the steel box girder. The invention further discloses a steel box girder assembling method. The steel box girder assembling method comprises the steps of A building a supporting frame; B laying a track; C jacking and transporting the steel box girder; D adjusting the three-dimensional space position of the steel box girder and assembling the steel box girder;and E finishing the assembly of the steel box girder. The steel box girder is high in assembly precision.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

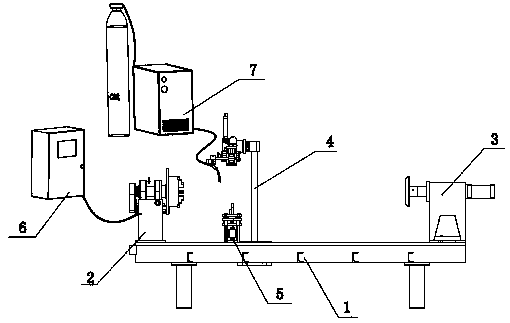

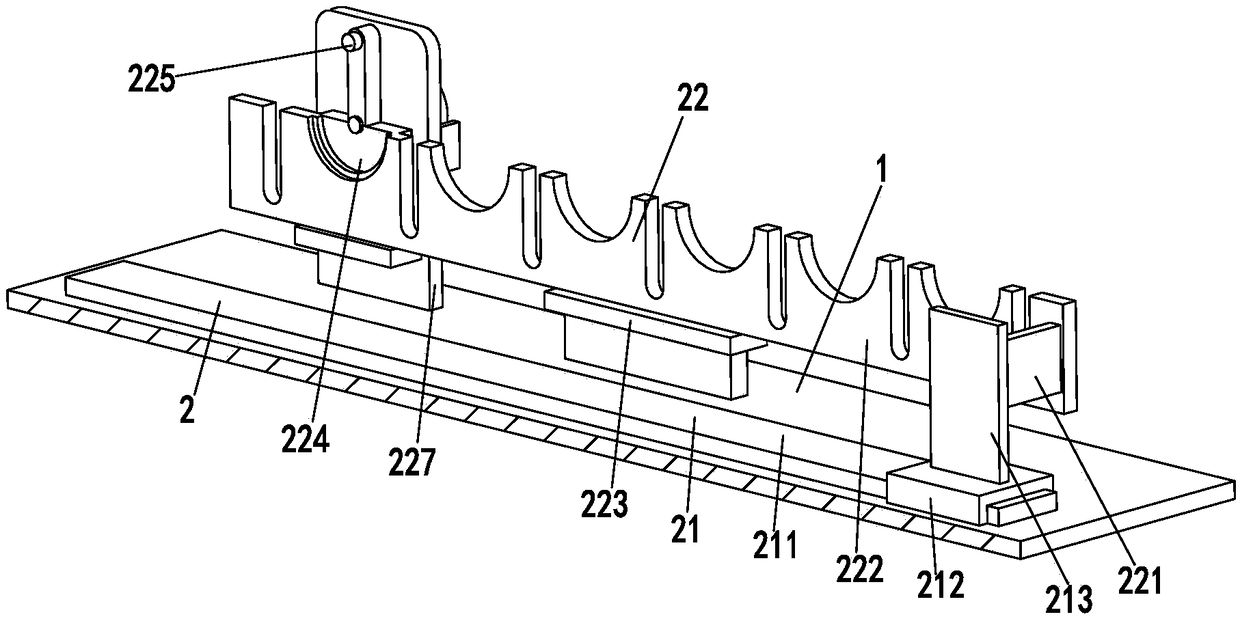

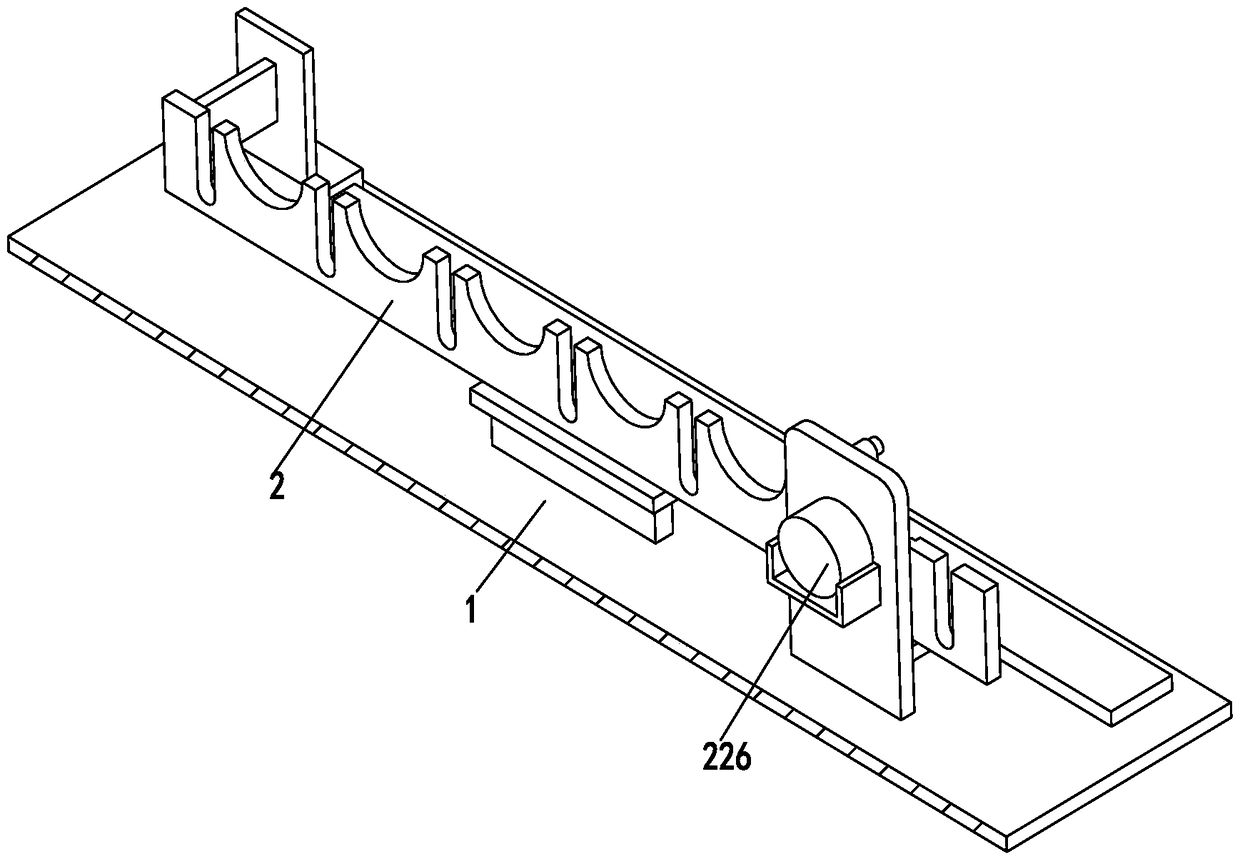

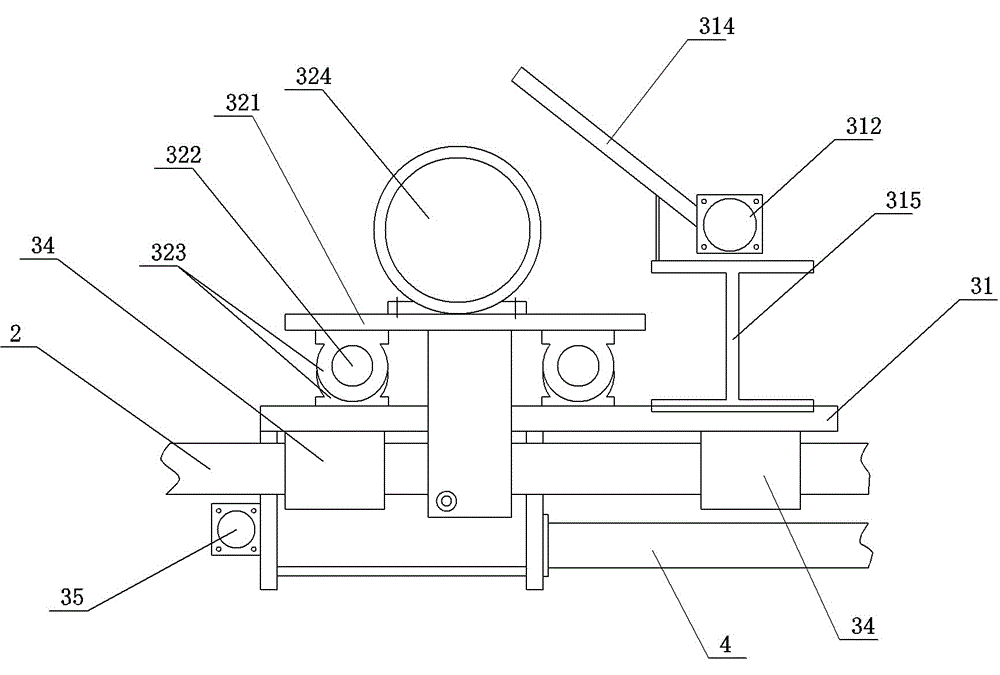

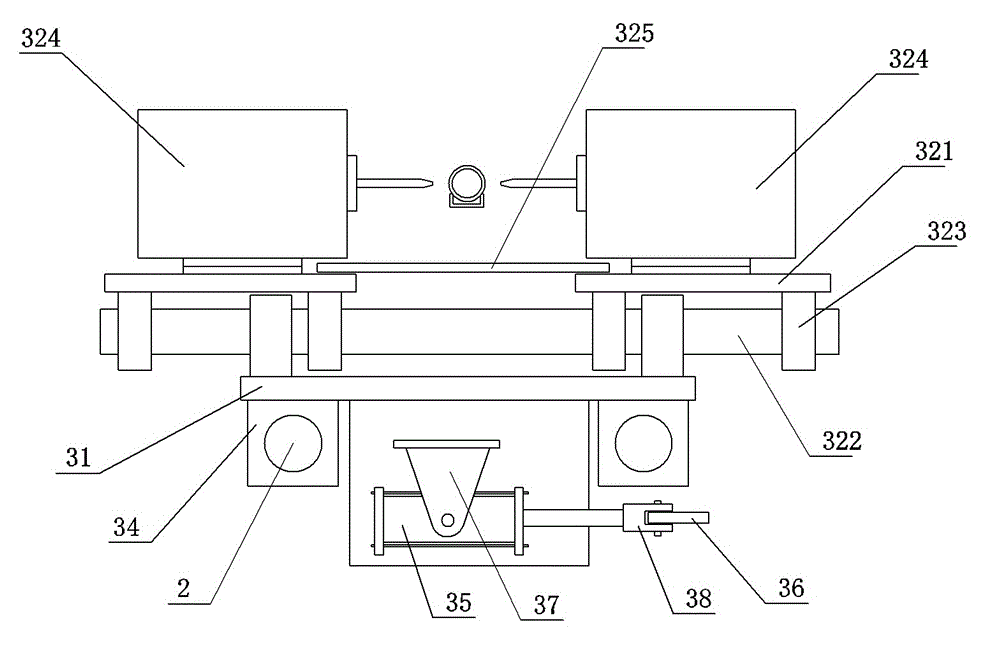

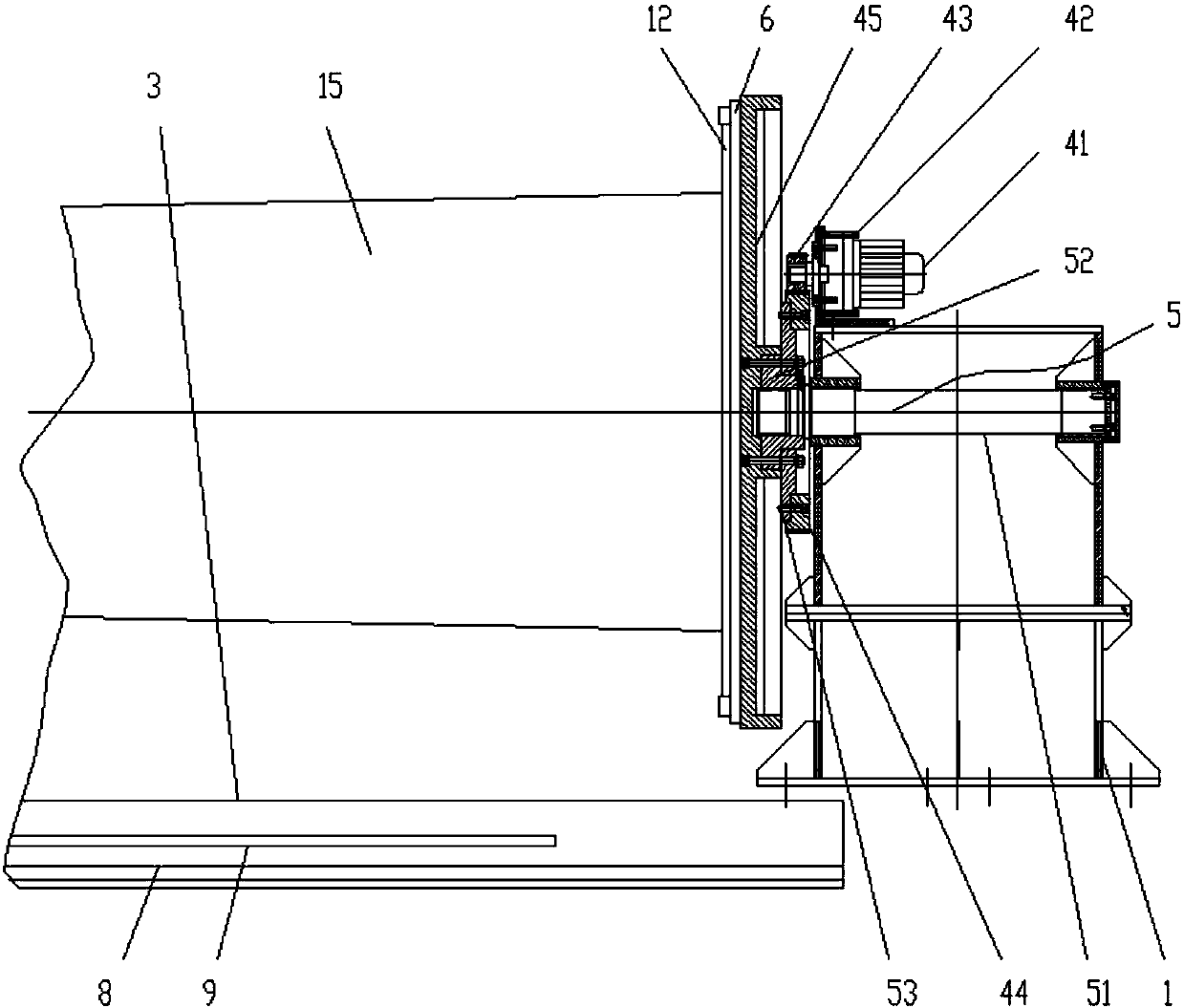

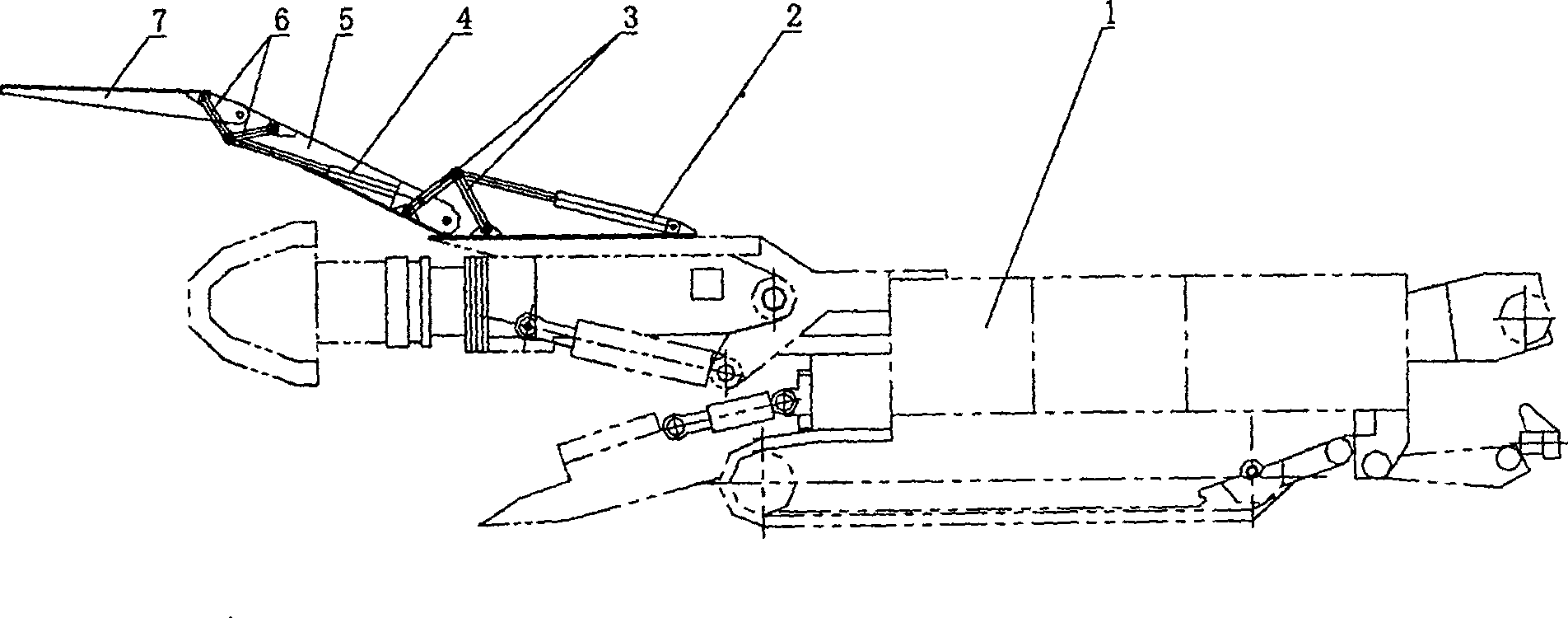

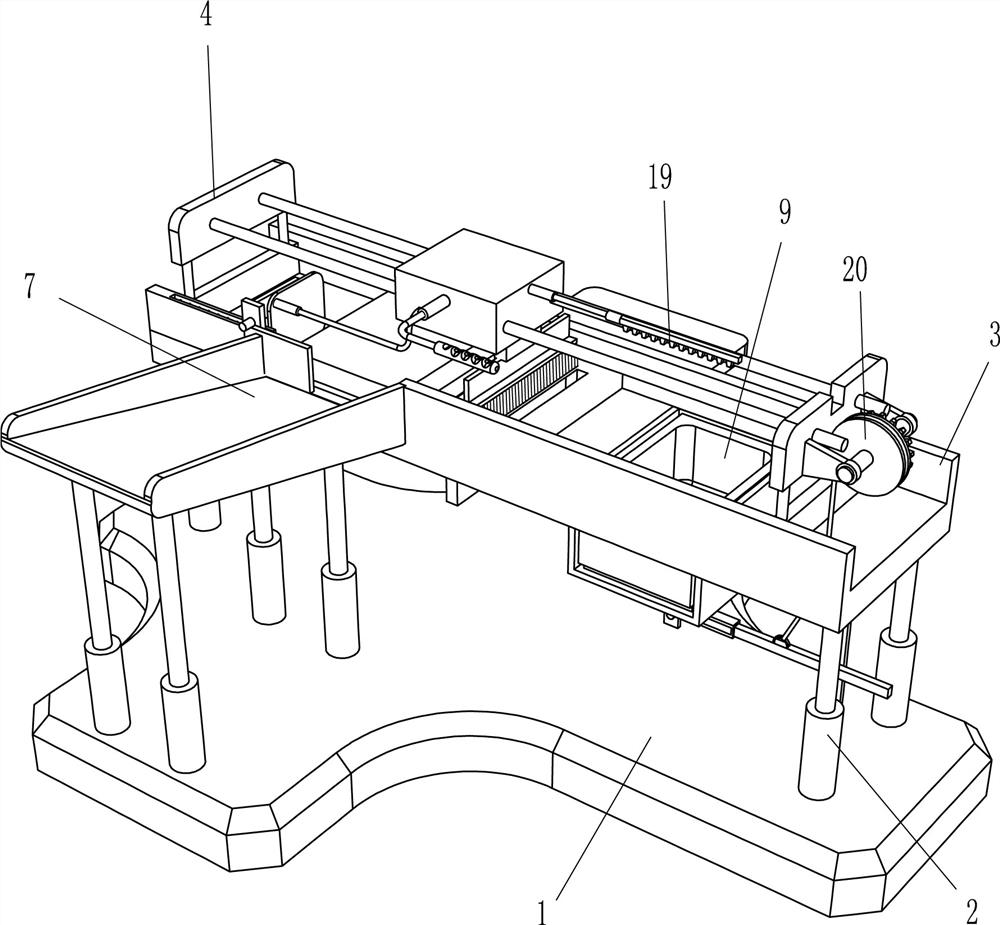

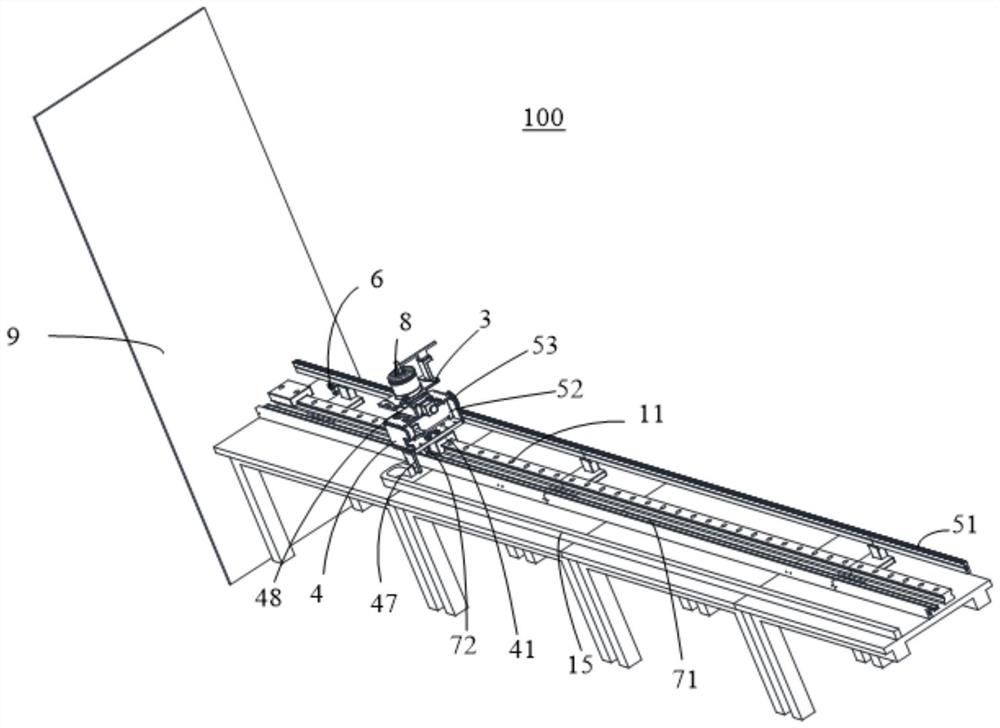

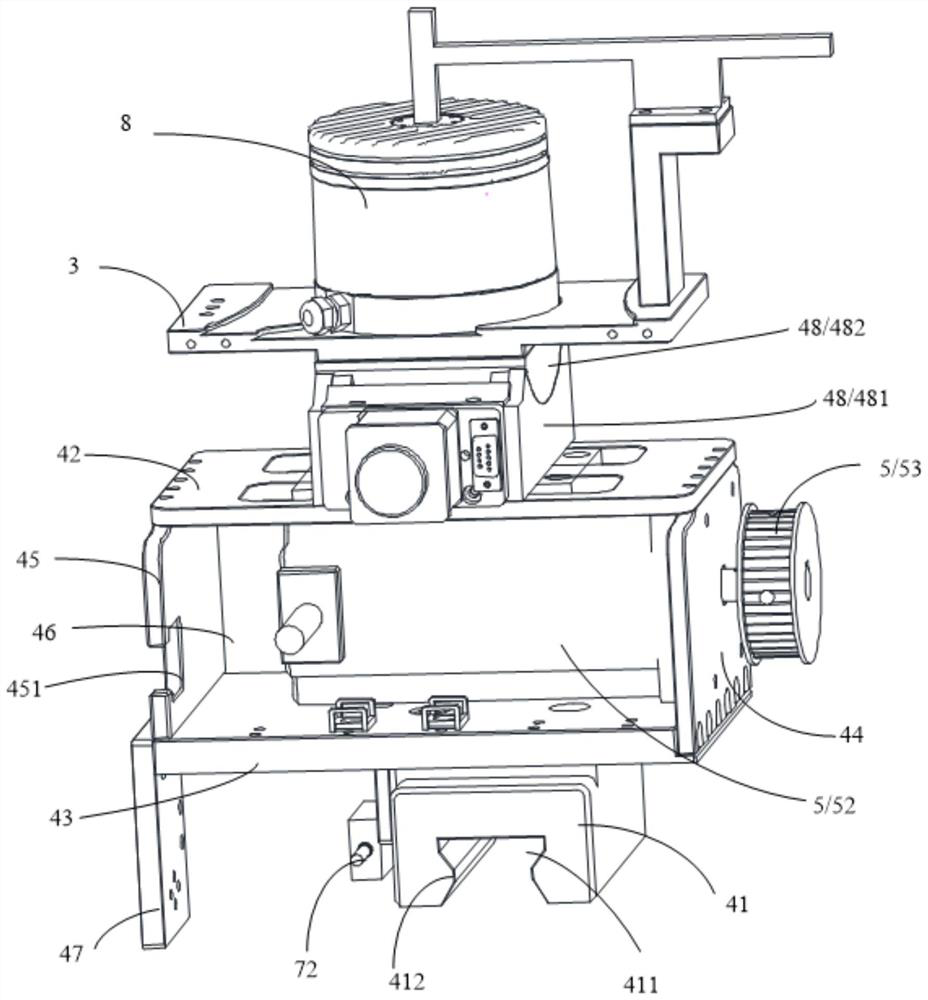

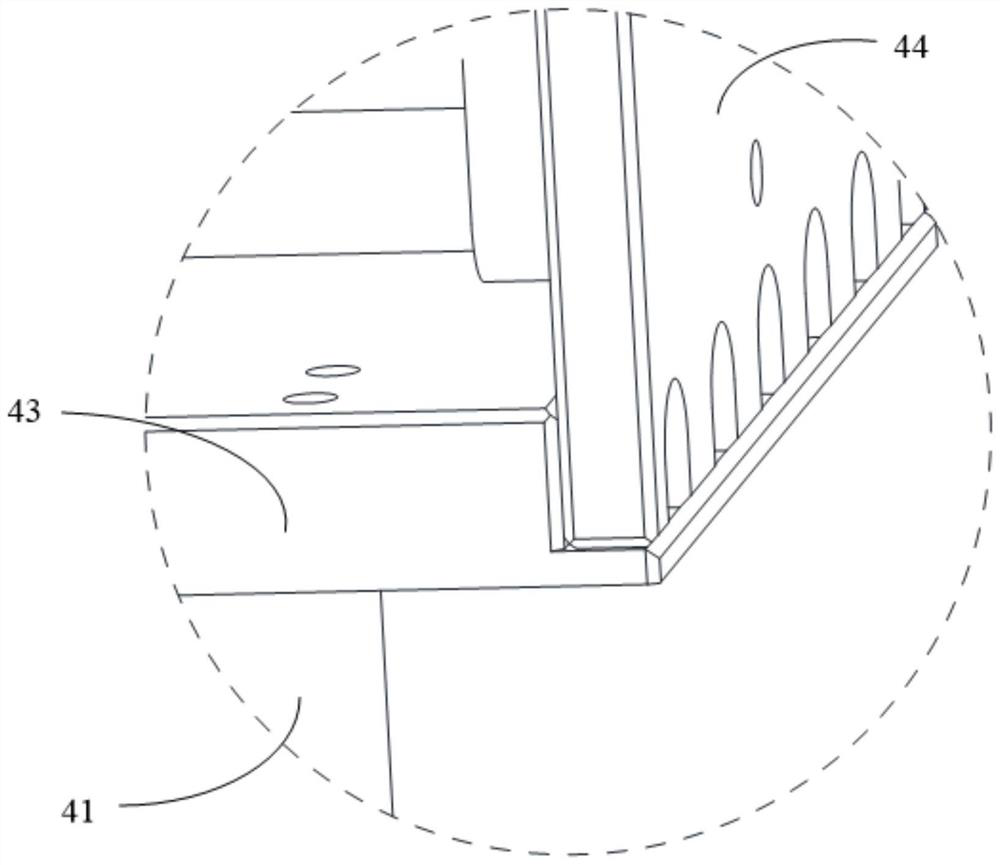

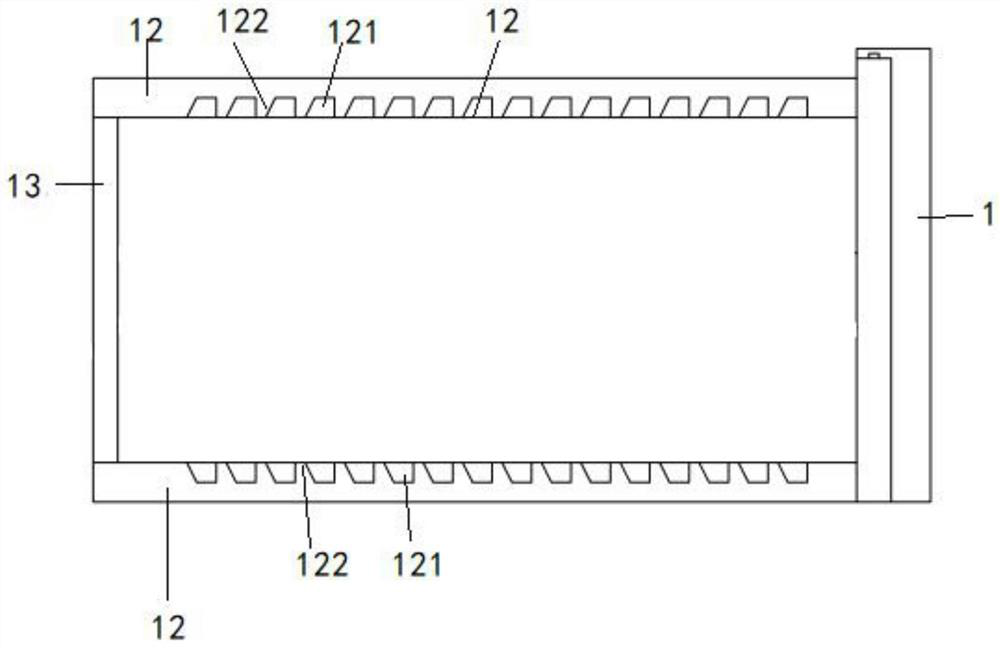

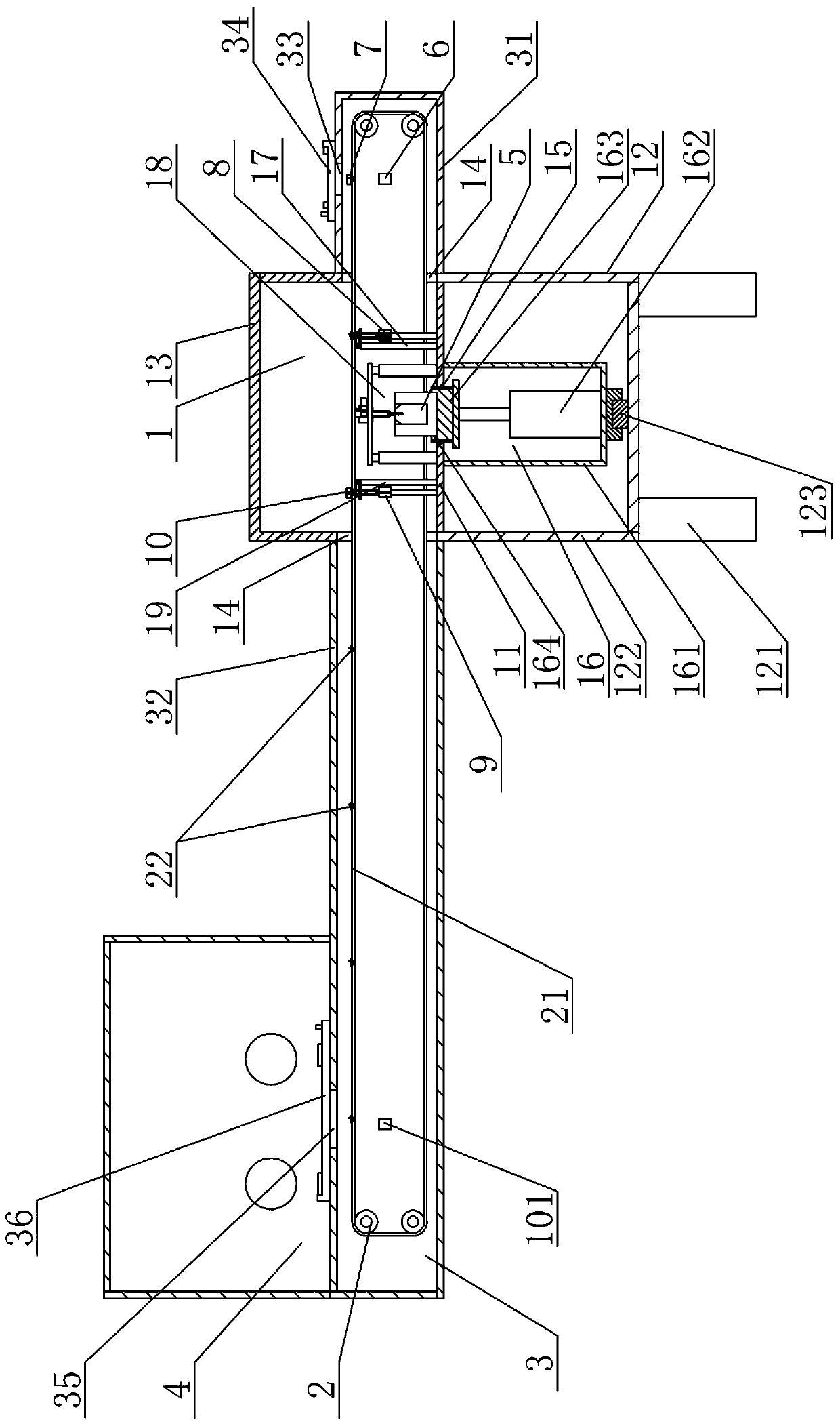

Gas pipe fitting automatic welding device

PendingCN109332987APlay a supporting roleHigh transmission precisionWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses a gas pipe fitting automatic welding device, which comprises a base. One end of the base is the power end, and the other end of the base is the tail end; a power machine head assembly body is installed at the power end, a sliding rail is formed in the upper surface of the base, a tailstock assembly body is installed at the tail end, the bottom of the tailstock assembly bodyis controlled by a tailstock air cylinder to slide on the sliding rail, a welding gun mechanism assembly body and an upper holding mechanismassembly body are further arranged between the power machine head assembly body and the tailstock assembly body on the base, the power machine head assembly body is connected with a PLC control box through wires, and the welding gun mechanism assembly body isconnected with a carbon dioxide protective welding machine. According to the gas pipe fitting automatic welding device, a rotating power machine head is adopted as a rotating power device of pipe fittings, and thus precise control of the required rotating angle can be realized; the tailstock assembly body is arranged, suitable adjustment can be carried out according to the specifications of the pipe fittings, manual movement is not required, and thus the labor cost is saved; and the welding gun mechanism assembly body is arranged, precision welding can be achieved, and the quality of weldingis ensured.

Owner:浙江金隆铜业股份有限公司

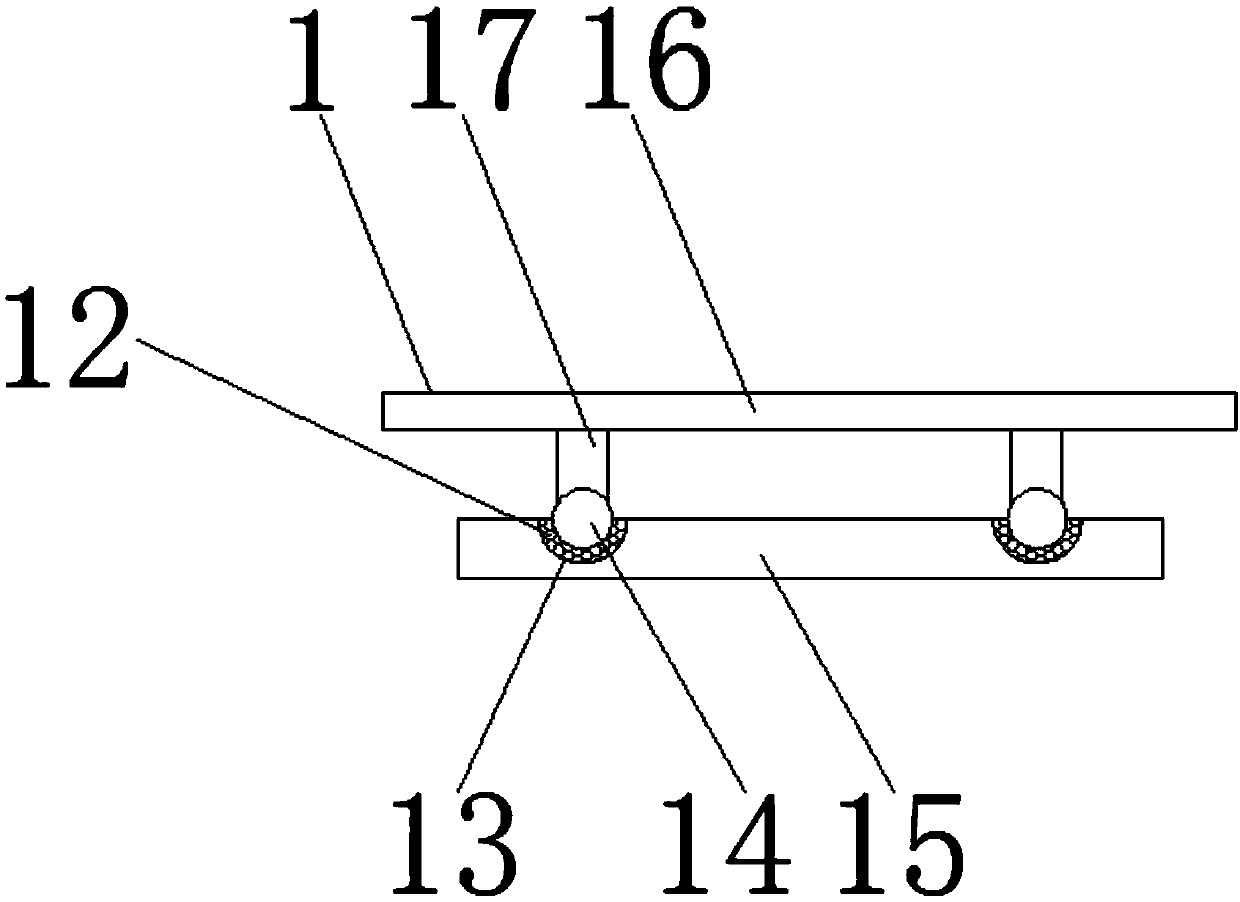

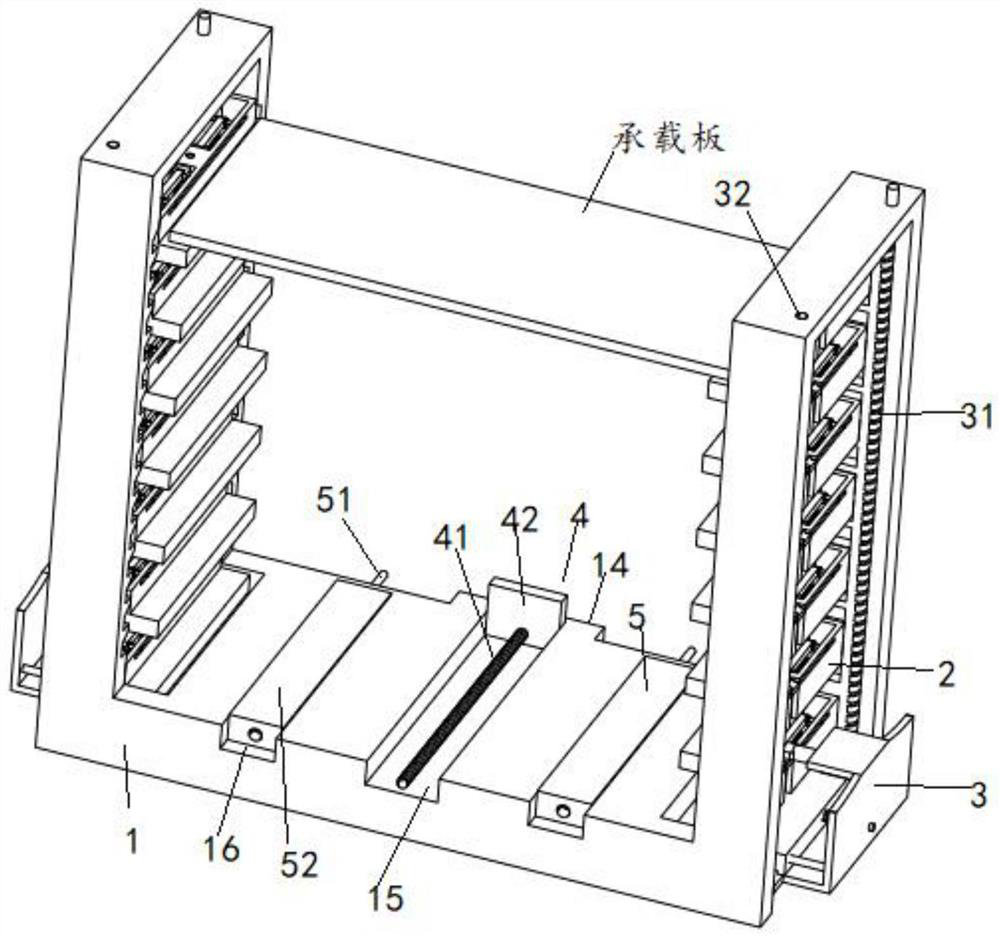

Processing technology of blended fabric

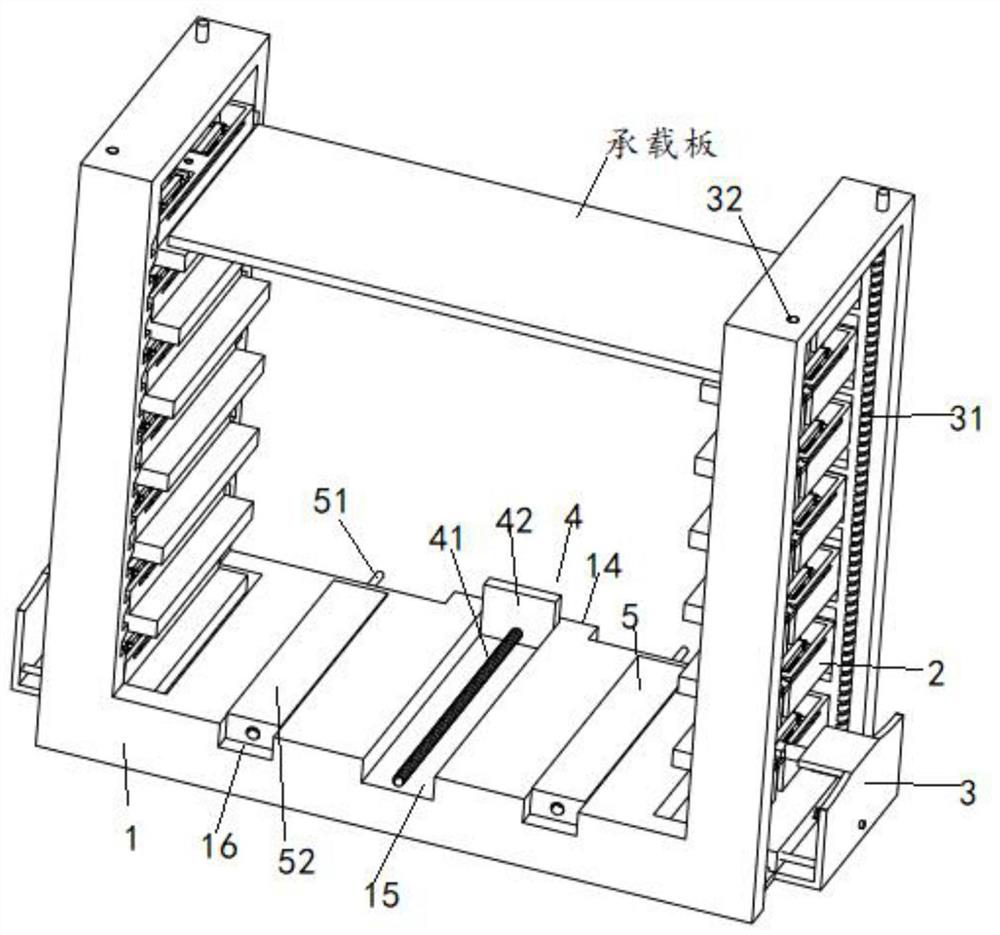

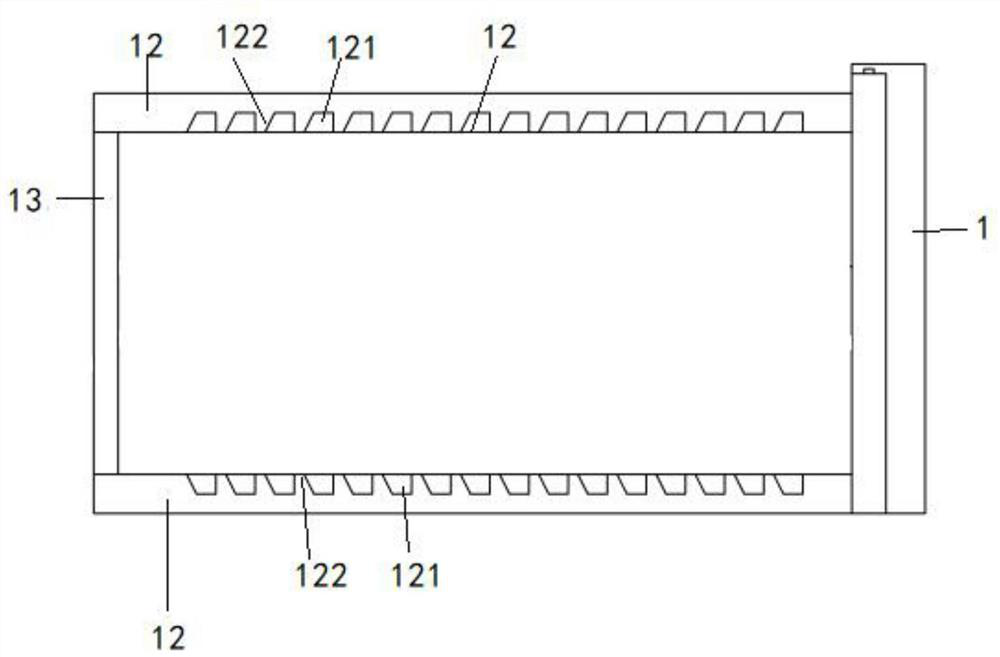

The invention discloses a processing technology of blended fabric. The processing technology comprises the following specific processing steps: blending and dyeing cotton fiber, polyester fiber, silver fiber and wool fiber in a mass ratio of 1: (0.6-0.9): (0.1-0.2): (0.5-0.6) to obtain a fabric, rolling the fabric by a cloth rolling machine to form fabric rolls, placing the obtained fabric rolls on bearing plates, and placing the bearing plates on a self-adaptive adjusting type stacking frame for stacking storage. In the fabric processing process, the obtained fabric roll is directly placed onthe self-adaptive adjusting type stacking frame, the number of storage layers and positions of the bearing plates for containing fabric are automatically adjusted directly through cooperation of an elastic bearing mechanism and a lifting unlocking mechanism in the stacking process, manpower is saved, the distance between the two bearing plates can be freely adjusted according to the stacking height of each layer, and storage space waste is avoided.

Owner:广东金西湖实业有限公司

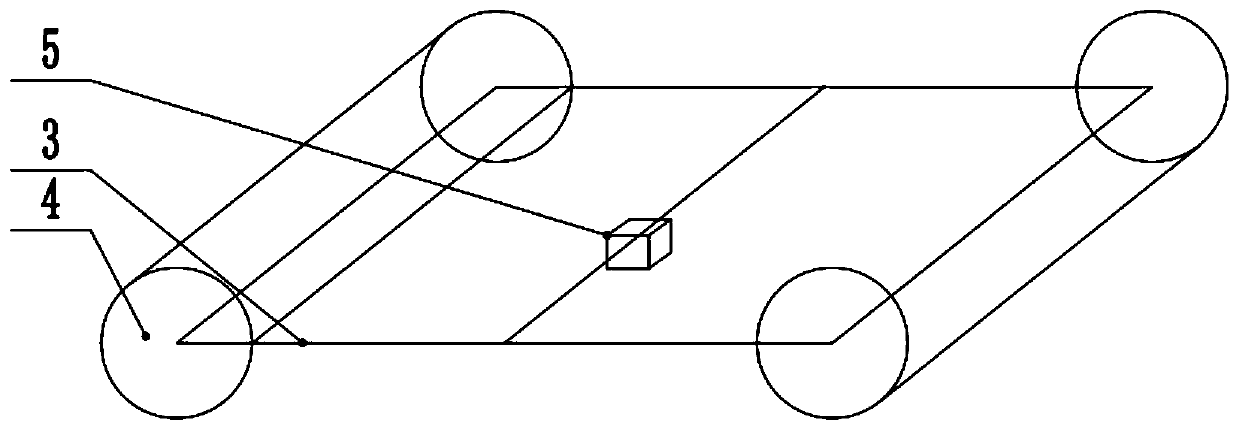

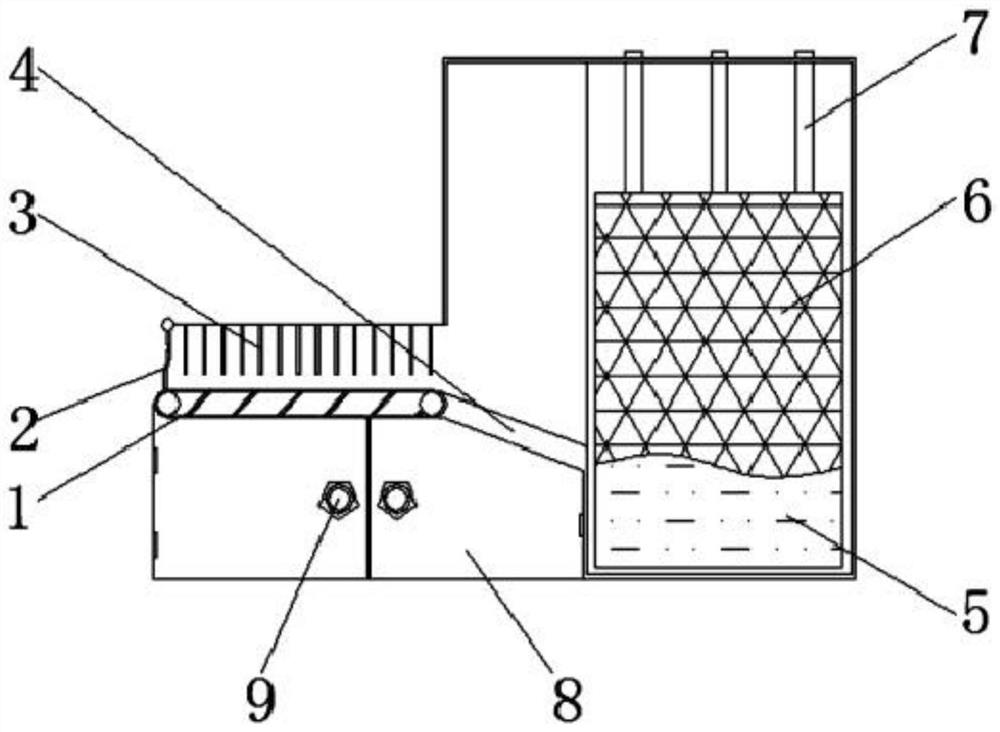

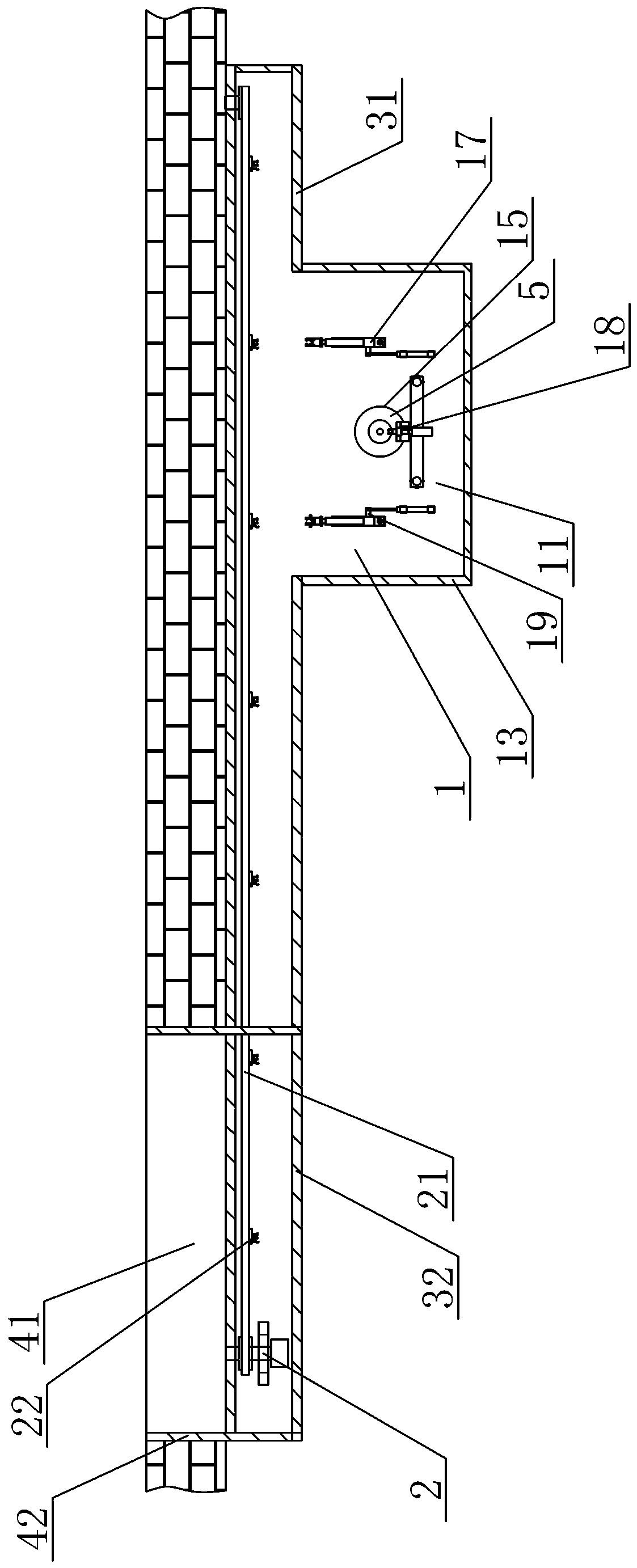

Construction device for anti-corrosion cloth of pipeline and anti-corrosion construction method

ActiveCN108716586ANo manual movementReduce labor intensityCorrosion preventionPipe protection against corrosion/incrustationEngineeringDrive motor

The invention relates to a construction device for anti-corrosion cloth of a pipeline and an anti-corrosion construction method. The construction device comprises a baseplate, moving devices, a rotating device and a bearing bracket, wherein the moving devices are symmetrically mounted on the front side and the rear side of the baseplate; the rotating device is connected between the moving devices;the bearing bracket is arranged at the right end of the rotating device and mounted on the baseplate; each moving device comprises a connecting mechanism and a driving mechanism; the rotating devicecomprises a fixing mechanism and a rotating mechanism; and each driving mechanism comprises a transverse plate, a movable trough plate, a supporting bracket, a rotating rack, a convex pillar, a driving motor and a working plate. The problems of high labor cost, high labor intensity, low working efficiency, nonuniform laying and the like in a conventional pipeline anti-corrosion cloth laying process are solved. Laying of the anti-corrosion cloth of the pipeline can be helped. The construction device has the advantages of low labor cost, low labor intensity, high working efficiency, uniform laying and the like.

Owner:兰州中人管道工程有限公司

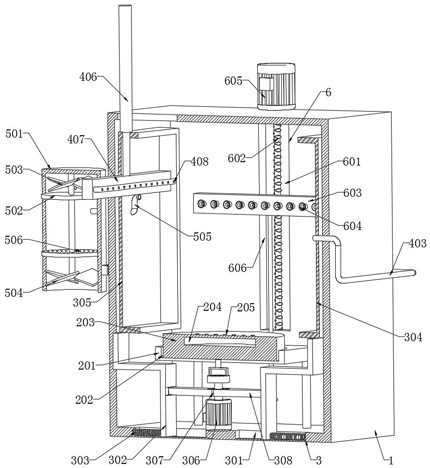

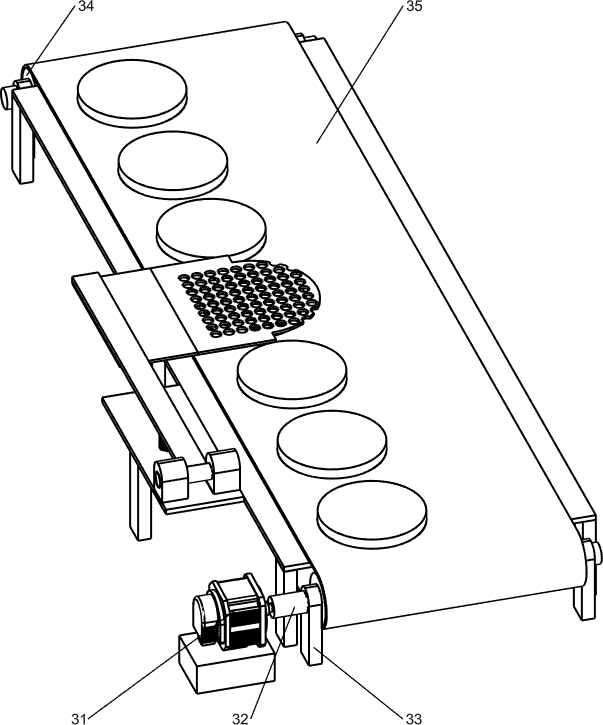

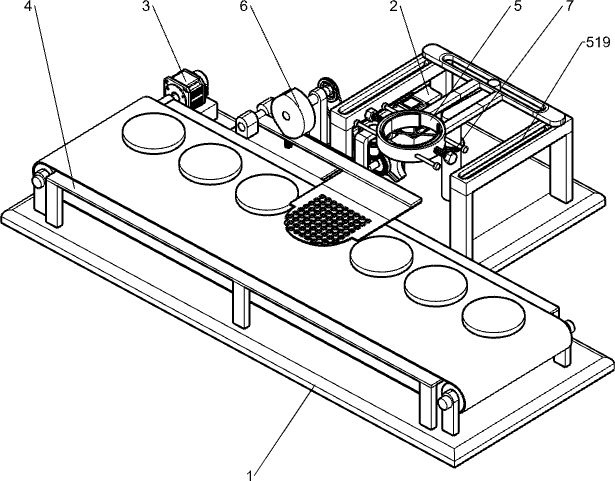

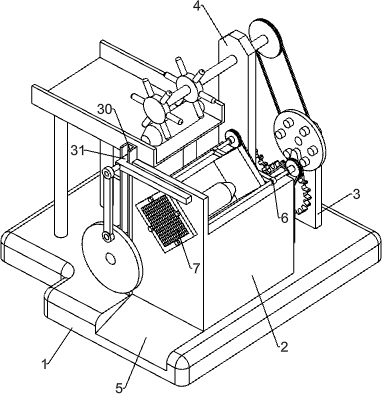

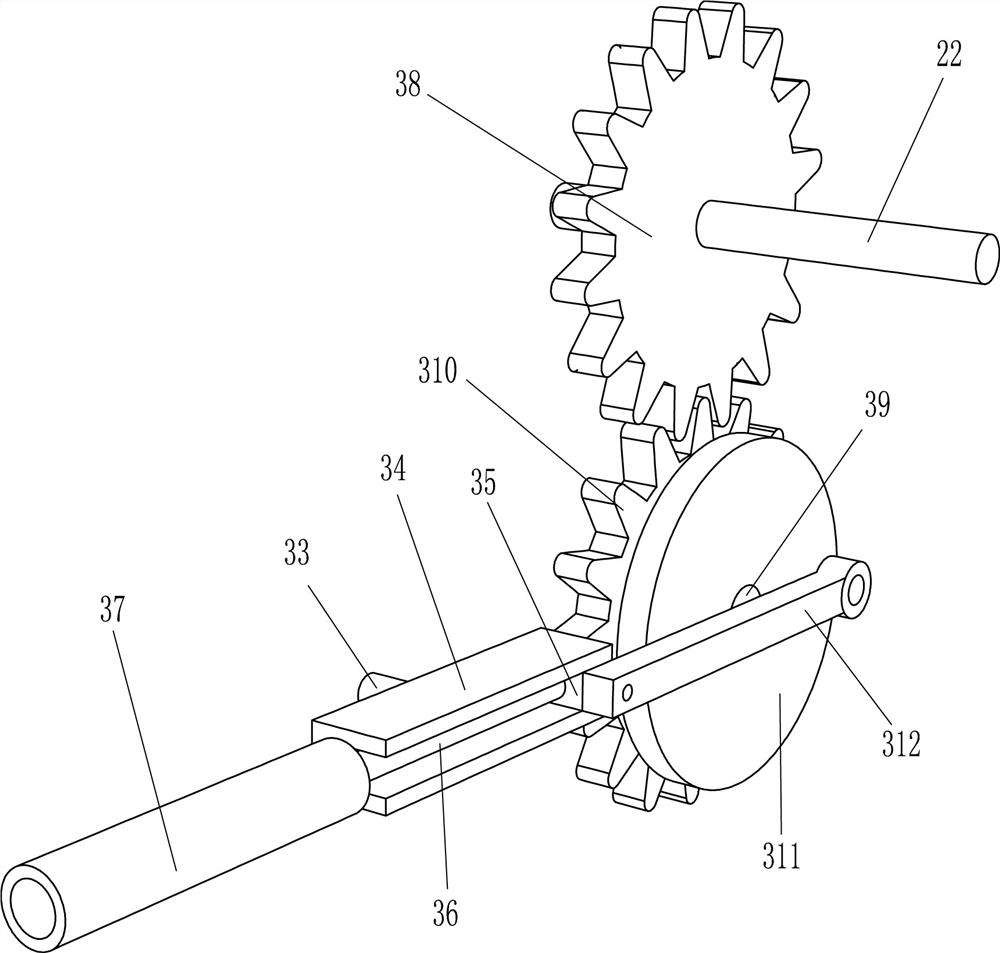

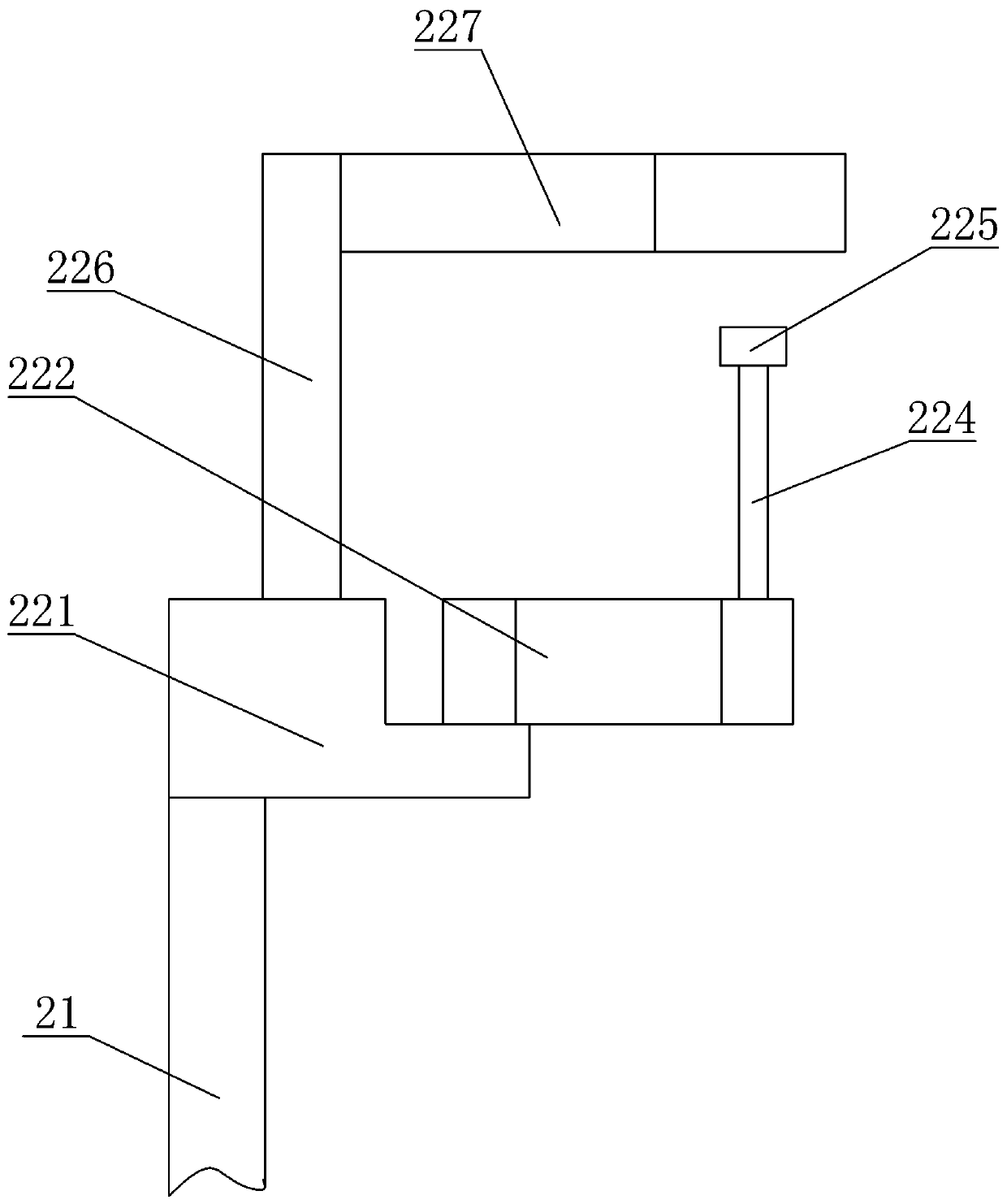

Floating powder suction device for pressed powder

PendingCN111790690ARealize automatic replacementNo manual movementCleaning using gasesElectric machineryEngineering

The invention relates to a floating powder suction device, in particular to a floating powder suction device for pressed powder. The floating powder suction device aims at achieving the technical purposes that a powder suction pipe can automatically move, pressed powder can be automatically fixed, and floating powder suction automation is achieved. According to the technical scheme, the floating powder suction device comprises a base and an intermittent mechanism, wherein a driving motor is installed on the rear side of the base, a powder conveying mechanism is arranged on the front side of the base, a working plate is installed on the front side of the base, the intermittent mechanism is arranged on the side, close to one side of the driving motor, of the base, and the intermittent mechanism is connected with the driving motor. The powder conveying mechanism drives the pressed powder to intermittently rotate, automatic replacement of the pressed powder is achieved, the powder suctionpipe does not need to be manually moved, the intermittent mechanism drives the powder suction pipe to intermittently move front and back, automatic floating powder suction of the powder suction pipe is achieved, the pressed powder is fixed through a powder pressing mechanism, the pressed powder does not need to be manually fixed, and the floating powder can be conveniently sucked away through thepowder suction pipe.

Owner:范芳芳

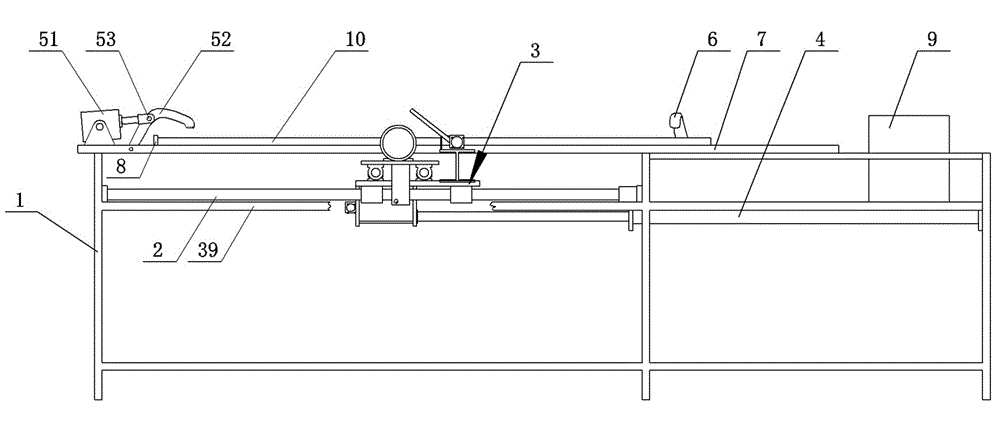

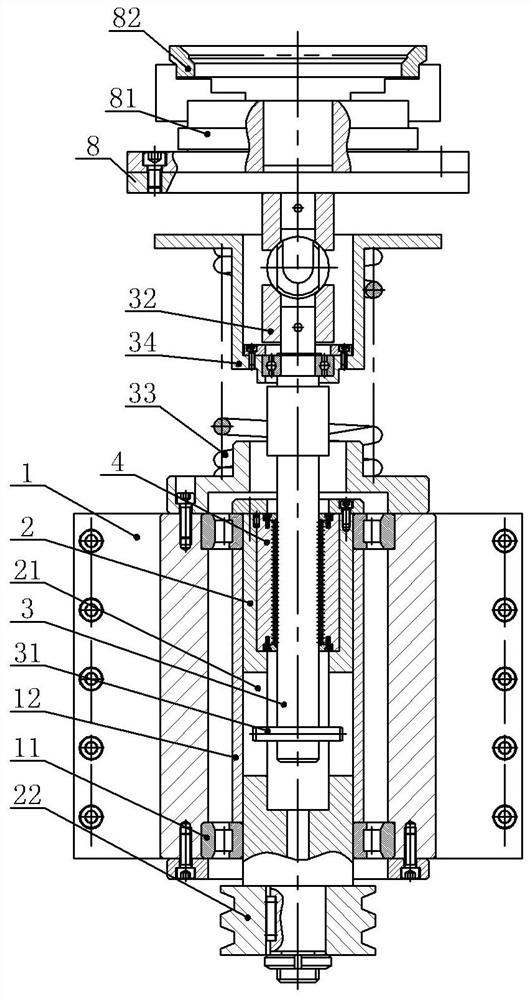

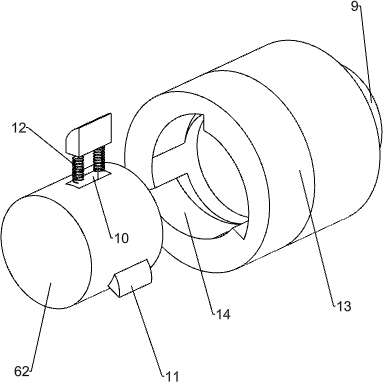

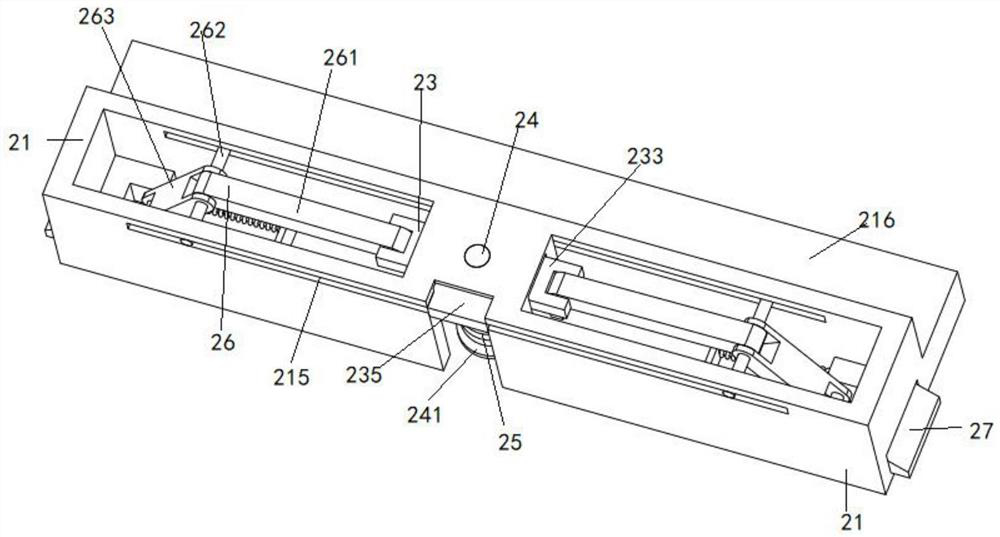

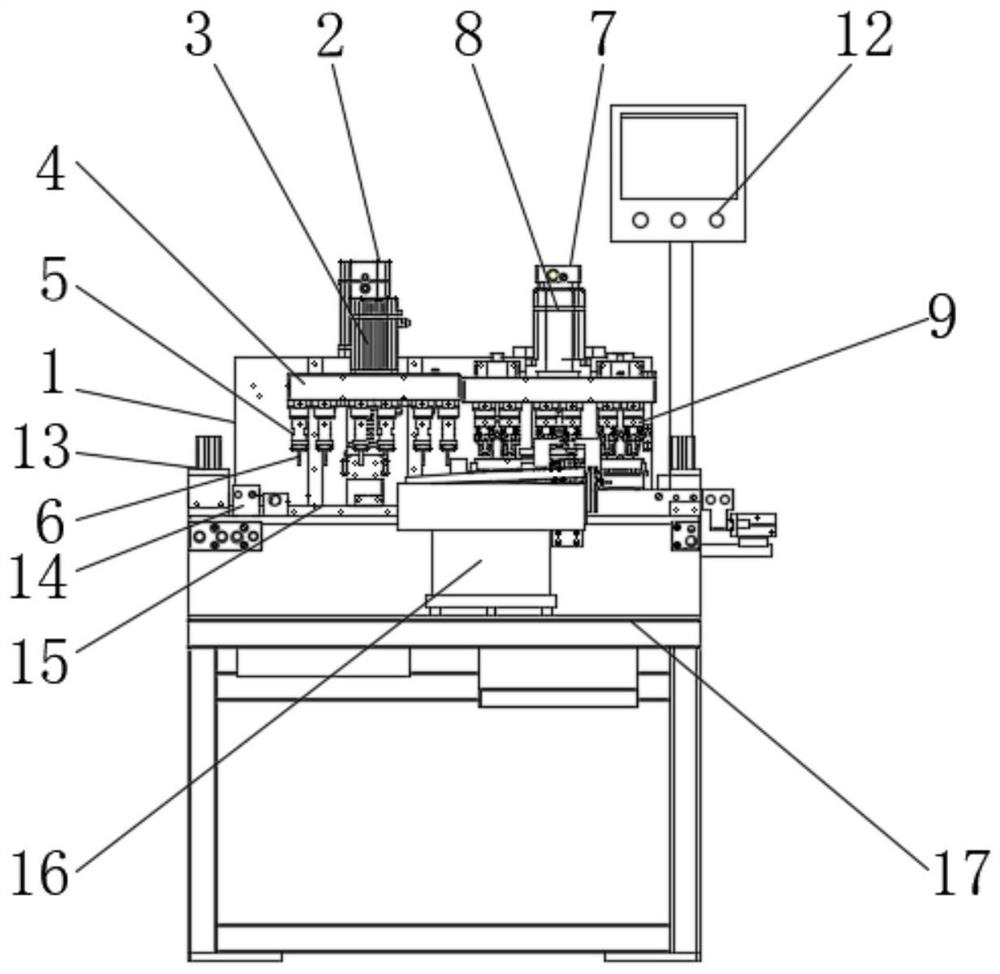

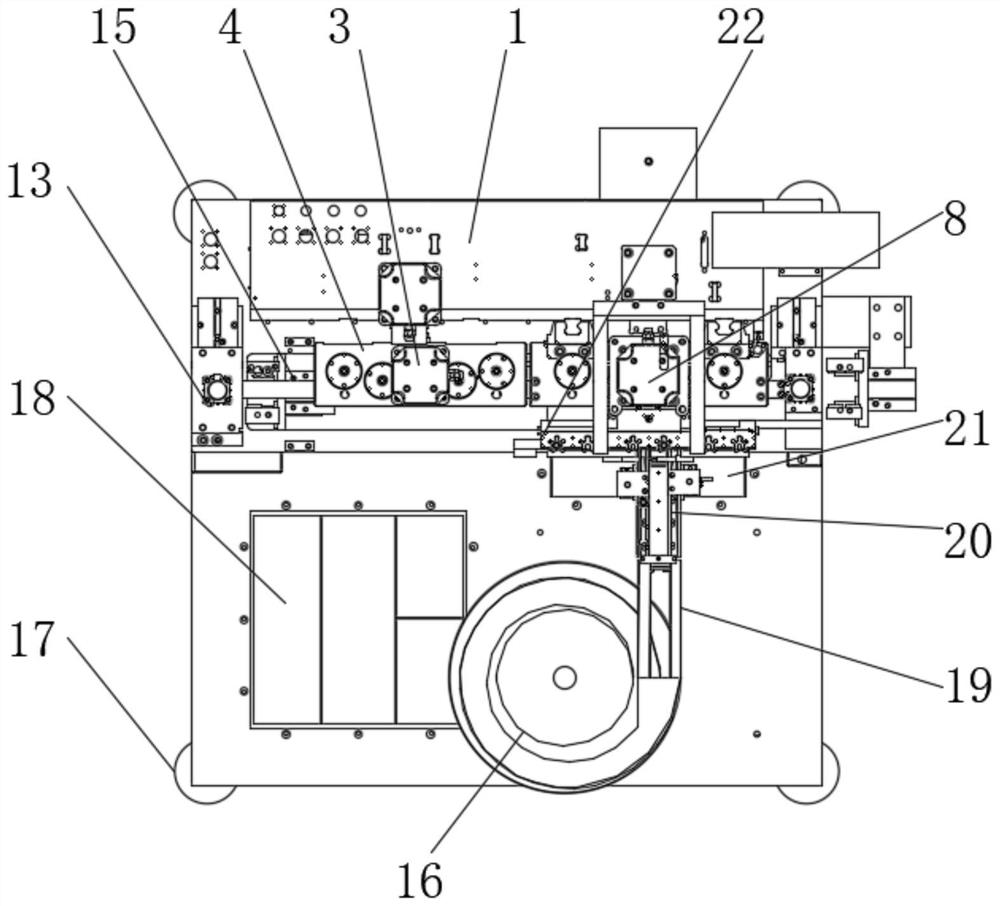

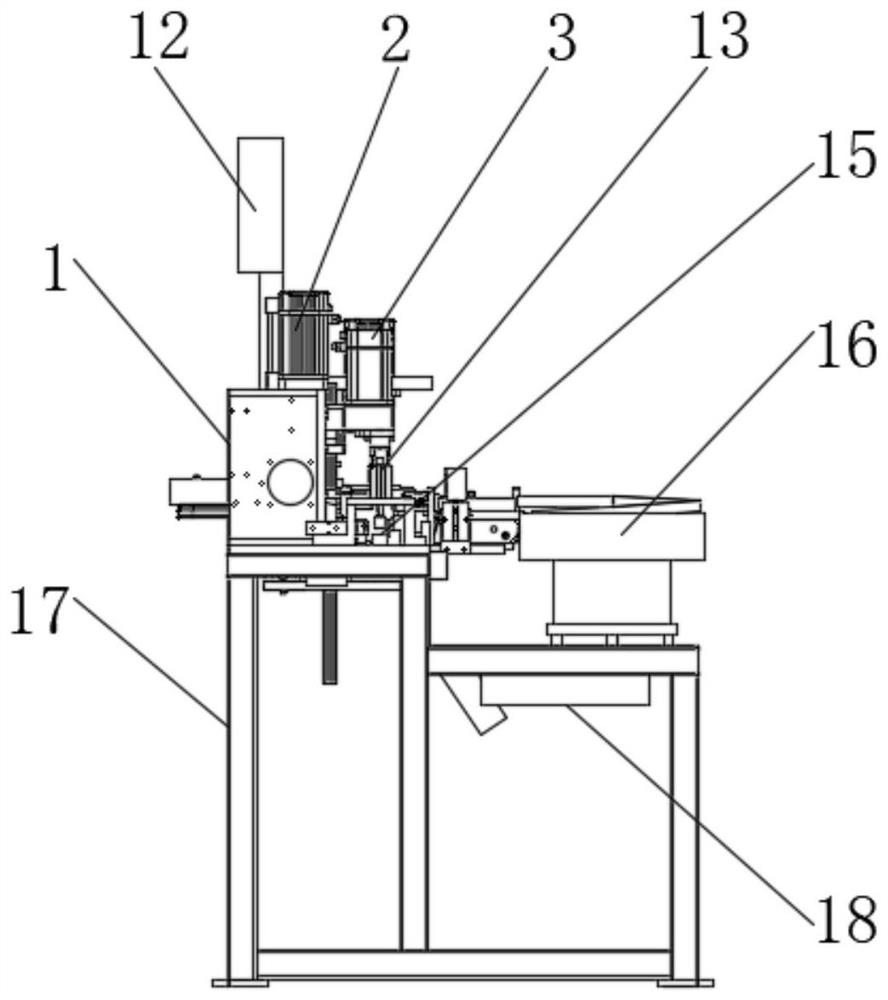

Circular tube drilling and pin pressing machine tool

InactiveCN104354007AGuaranteed machining accuracyTimely positioningTurning machine accessoriesWorkpiecesEngineeringAtmospheric pressure

The invention discloses a circular tube drilling and pin pressing machine tool. The machine tool comprises a rack, a walking platform, a positioning mechanism, a drilling rig, a hydraulic or pneumatic system, an electric appliance cabinet and the like, wherein the middle part of the rack is provided with a steel tube positioning groove along the longitudinal direction; the front and rear ends of the steel tube positioning groove are provided with clamps respectively; the rear part of the walking platform is provided with a drilling hole, and the front part of the walking platform is provided with a pin pressing device. According to the machine tool, automatic drilling and automatic pin pressing work can be realized, a worker does not need to participate in the pin pressing work, the degree of automation is high, the efficiency is high, the effect is good, and the human resource and cost are saved.

Owner:郑州市嵩阳煤机制造有限公司

Welding process for diode production

ActiveCN112453613AReduce labor intensityWeld firmlySoldering auxillary devicesEngineeringWelding process

The invention discloses a welding process for diode production. The welding all-in-one machine comprises a feeding mechanism, a welding mechanism is arranged on the rear surface of the upper portion of the feeding mechanism, and a conveying belt is horizontally arranged at the position, located below the welding mechanism, of the rear surface of the feeding mechanism. The invention relates to thetechnical field of diode welding, in particular to a welding process for diode production, the middle of the outer surface of a rotating shaft is sleeved with a worm sleeve, the front surface of the upper portion of a storage box is rotationally connected with a worm wheel corresponding to the worm sleeve, the worm wheel is meshed with the worm sleeve, and the front surface of the worm wheel is fixedly connected with a first servo motor; and when a diode is welded, bonding pads needing to be used are stacked on a feeding plate in the storage box, and then under the work of the first servo motor and an electric push rod, the bonding pads on the feeding plate can be sequentially pushed out of a discharging groove and moved to the position of a welding head, and manual taking is not needed.

Owner:JIANGSU BAO PU LAY SEMICON

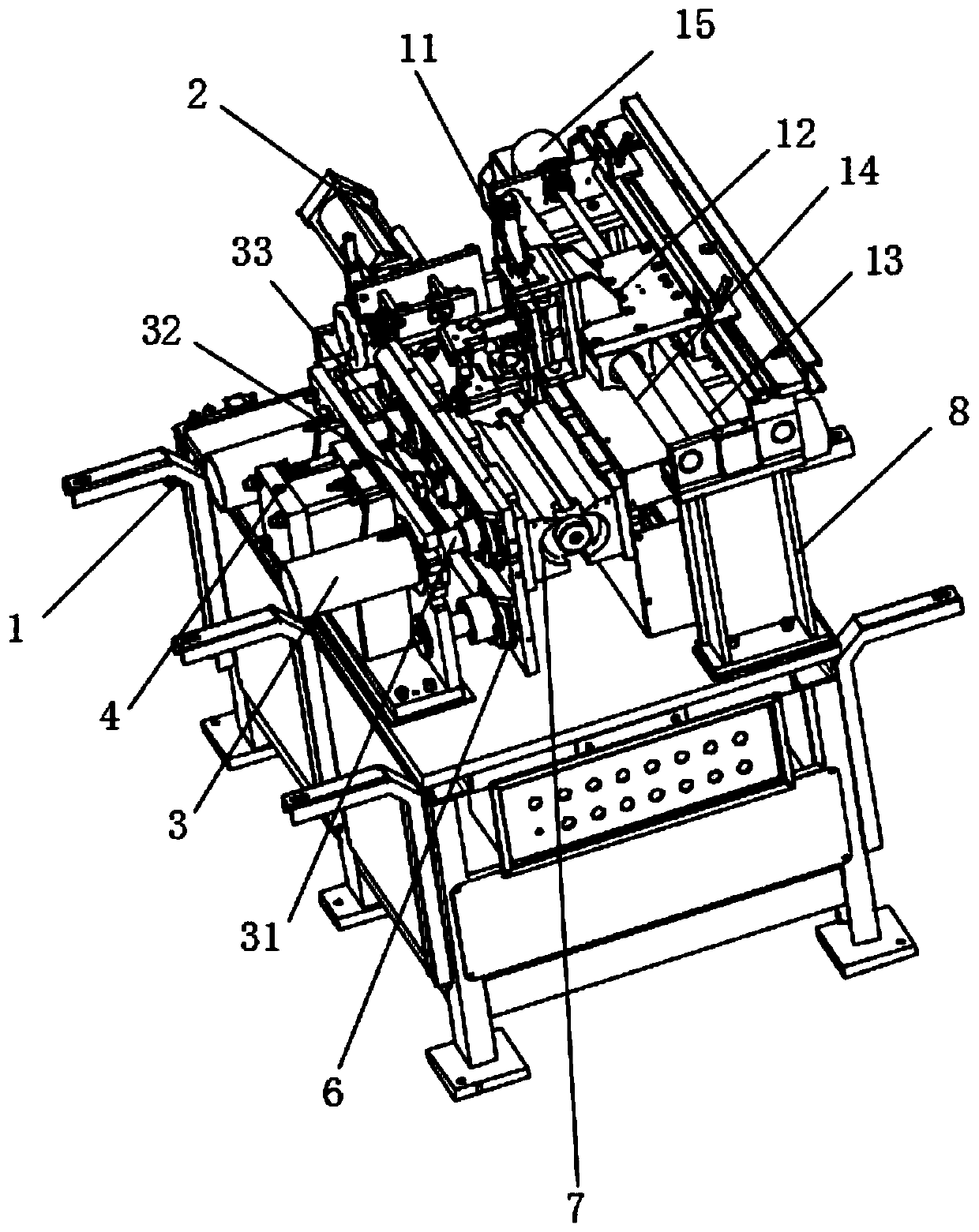

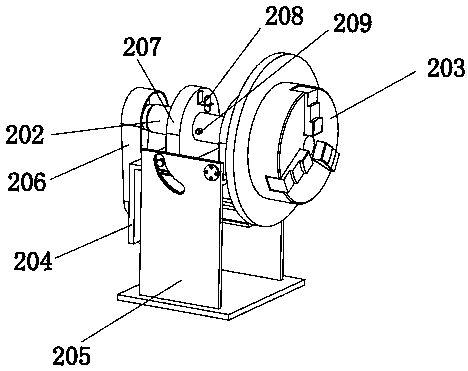

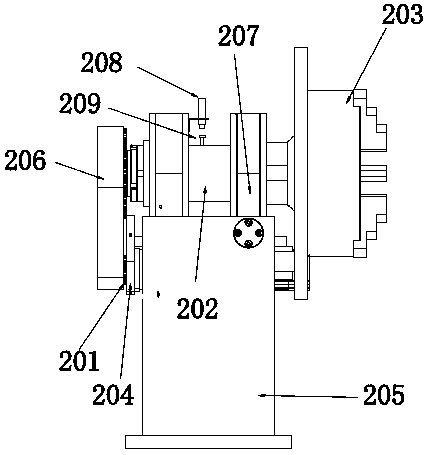

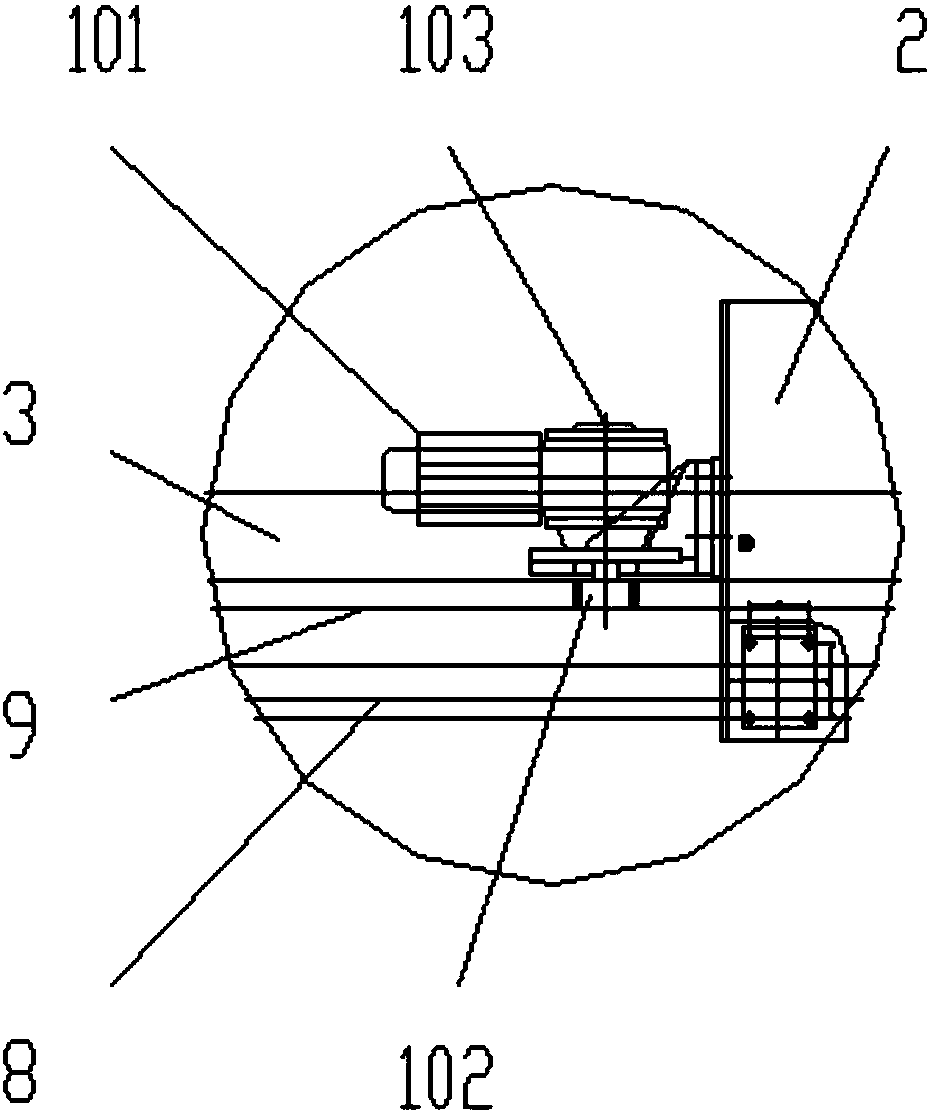

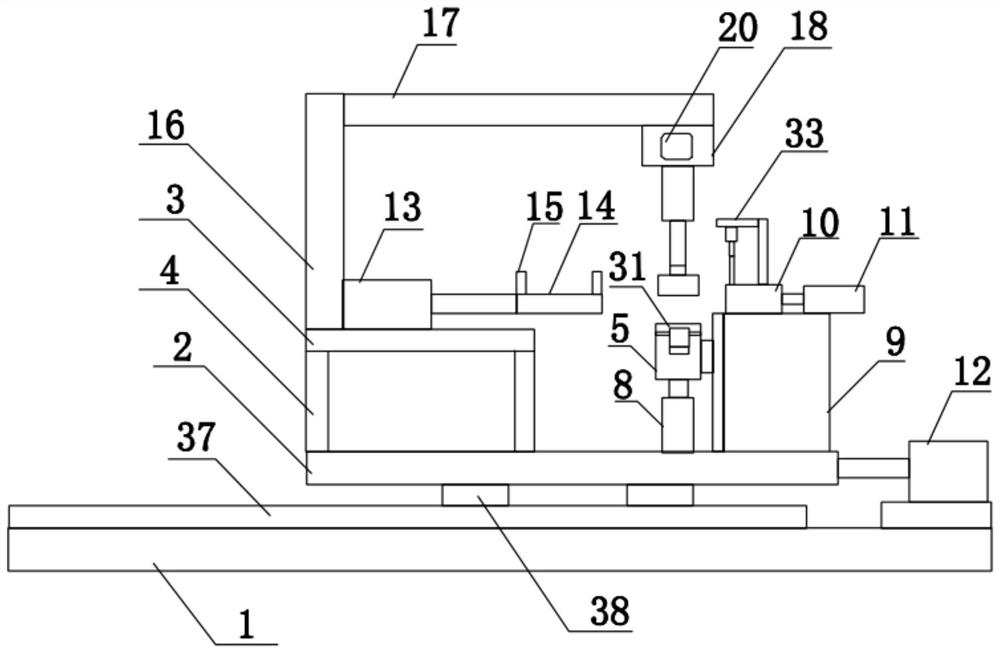

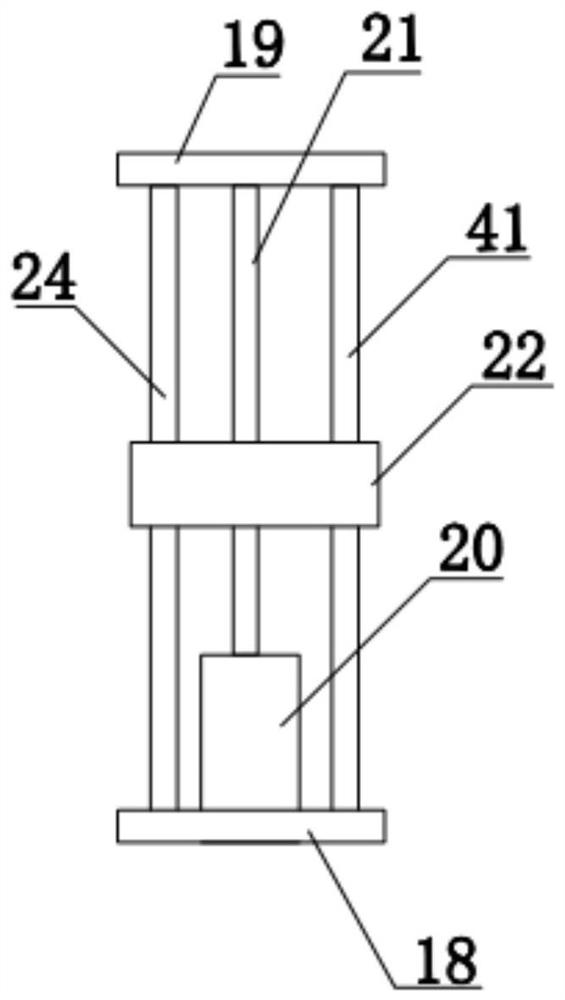

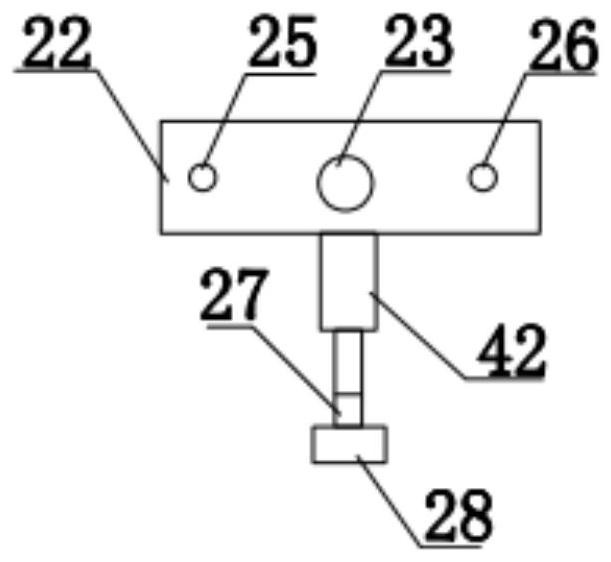

Rotary positioning system for steel pipe pole of power transmission line

InactiveCN107775257AHigh transmission precisionTransmission accuracy is stableWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTailstock

The invention discloses a rotating positioning system for a steel pipe pole of a power transmission line, which relates to the field of power transmission equipment and includes a driving end, a tailstock and a bottom frame. The side is provided with a guide rail, the tailstock is slidably connected to the guide rail through a slider, the slider is provided with a tailstock positioning mechanism, and a four-jaw chuck is installed on the rotary power machine head and the tailstock. The invention can realize the precise control of the rotation angle of the steel pipe pole. The tailstock adopts a movable structure, so it can be adjusted appropriately according to the specification of the steel pipe pole. This structure is also conducive to the installation and positioning of the steel pipe pole, and the overall degree of automation is high.

Owner:ANHUI JIXI JIADE STEEL STRUCTURE

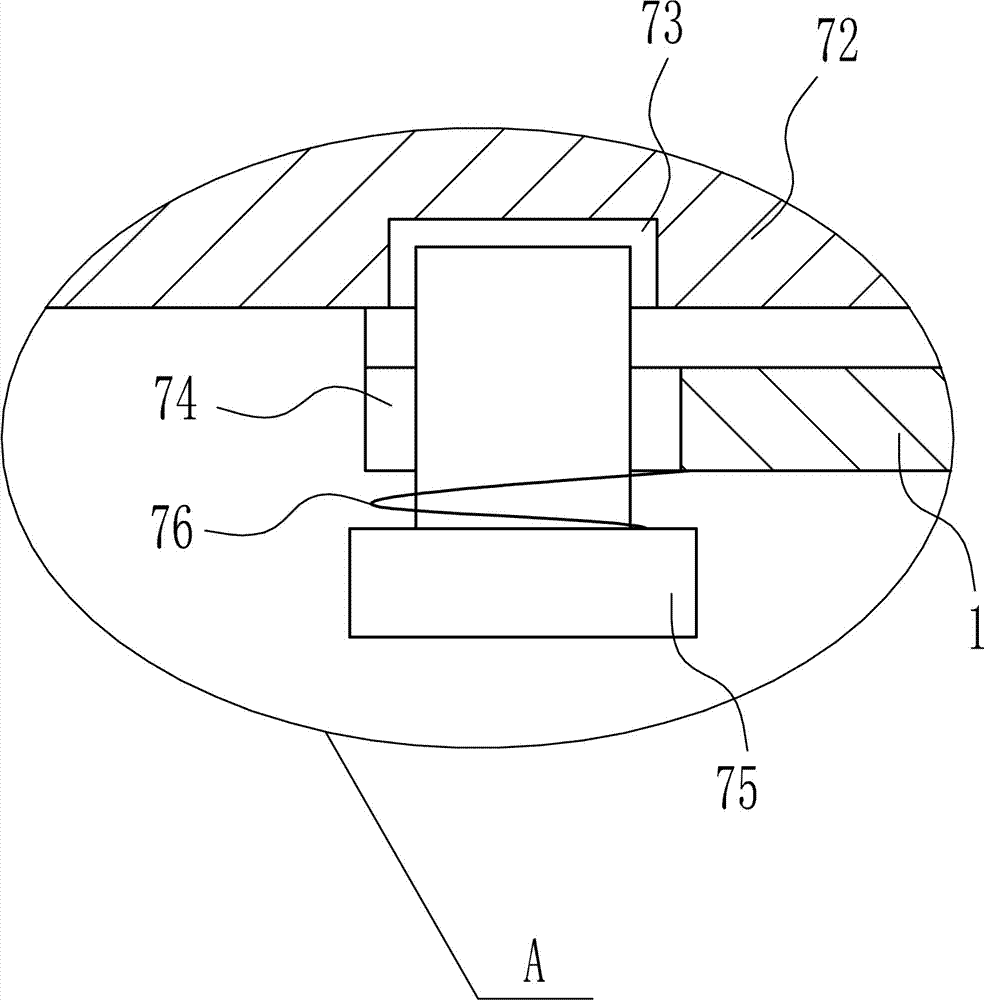

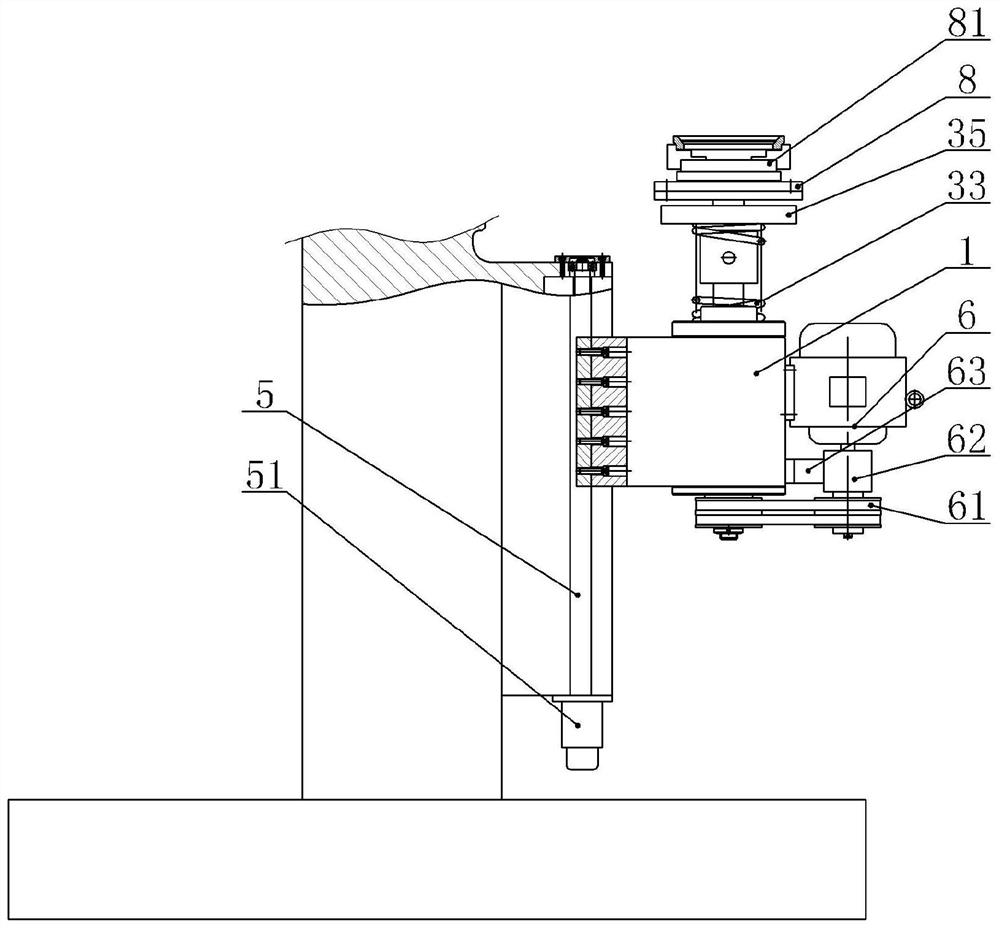

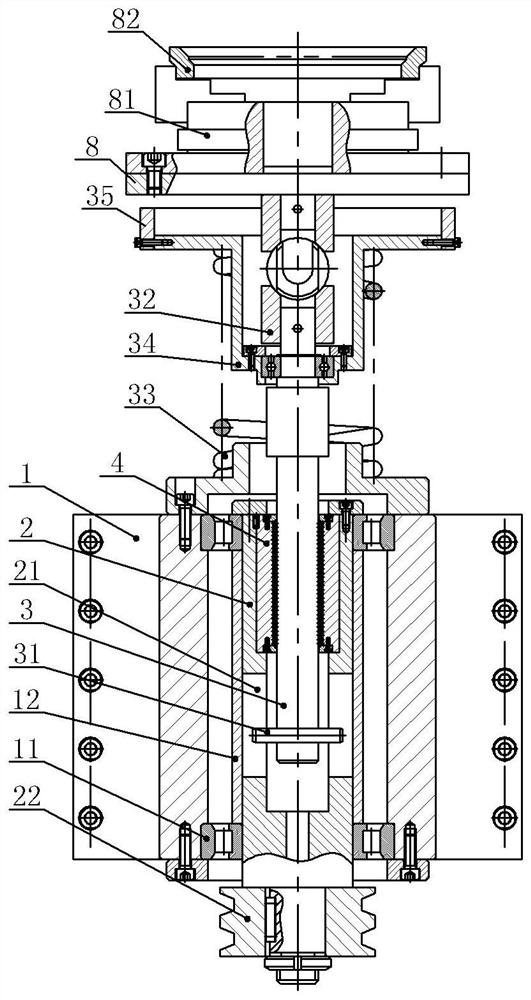

Valve seat grinding, clamping and moving device

PendingCN112157528ASlide fastReduce workloadGrinding drivesSeat surface grinding machinesDrive shaftMachining

The invention relates to the field of valve machining, in particular to a valve seat grinding, clamping and moving device. The device comprises a lathe bed, a valve seat clamping mechanism and a valveseat clamping and moving mechanism, wherein the valve seat clamping mechanism comprises a transmission main shaft, a transmission shaft, a clamping mechanism base and a spring; the transmission mainshaft penetrates through the clamping mechanism base, a fixing groove is formed in the transmission main shaft, the transmission shaft is coaxial with the transmission main shaft, and a rectangular linear bearing is arranged between the transmission shaft and the transmission main shaft; the upper end of the transmission shaft is connected with a self-centering chuck; the spring is positioned between the transmission main shaft and the self-centering chuck; the valve seat clamping and moving mechanism comprises a lead screw, and the lead screw penetrates through the clamping mechanism base andthe lathe bed and is in threaded fit with the clamping mechanism base; a guide groove is formed in the lathe bed in the axial direction of the transmission shaft; and the clamping mechanism base is connected with the guide groove in a sliding manner. The valve seat grinding, clamping and moving device disclosed by the invention can drive a valve seat to move, so that the workload of workers is reduced, and the machining efficiency is improved.

Owner:CHONGQING CHUANYI CONTROL VALVE

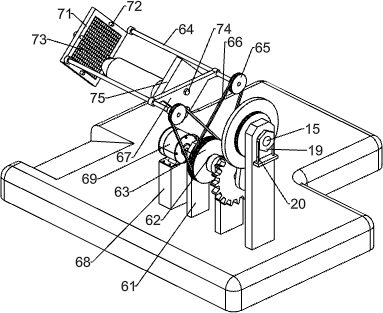

Potato shredding device

ActiveCN111660332AImprove efficiencyEasy to collectMetal working apparatusOperations securityOperational safety

The invention relates to a shredding device, and particularly relates to a potato shredding device. The technical problem of the potato shredding device is to provide the potato shredding device thatcan automatically cut potatoes into shreds, realize automatic cutting of potatoes without repeatedly taking the potatoes, and improve operational safety. According to the technical scheme, the potatoshredding device comprises a base and a transmission mechanism; the side portion of the base is provided with a V-shaped groove support, and the front portion, close to one side of the V-shaped groovesupport, of the base is provided with an inclined face; and the transmission mechanism is arranged on the rear side of the base close to one side of the V-shaped groove support, and a cutting mechanism is mounted on the front part of the V-shaped groove support and a part of the transmission mechanism. By means of the transmission mechanism, the potatoes can be pushed to move and make contact with the grid blades, manual moving of the potatoes is not needed, the potatoes are cut through the cutting mechanism, the potatoes are automatically cut into shreds, the potato cutting efficiency is improved, the potatoes can intermittently fall off through a shifting wheel, and automatic discharging of the potatoes is achieved.

Owner:黄思华

Geotechnical investigation test sample density testing system

PendingCN109870386ANo manual movementCapable of continuous measurementSpecific gravity measurementContinuous measurementTest sample

The invention relates to the technical field of geotechnical investigation, and discloses a geotechnical investigation test sample density testing system. The testing system comprises a sample guidingsystem, and further comprises a weighing system, a sample volume detecting system and a computer data processing system. The testing system is suitable for geotechnical investigation test sample density testing; the weighing system and the sample volume detecting system are used for measuring weight and volume information of a sample; measuring results are sent to the computer data processing system for calculation; and finally the density of the sample is obtained. The whole device moves through the sample guiding system in a running process, and the sample does not need to be manually moved, so that the use is more convenient; the testing system has the functions of continuous measurement, automatic identification, automatic recording, automatic calculation and automatic storage; and meanwhile, the computer data processing system protects the normal operation of the whole device through a program set in the computer data processing system.

Owner:浙江省工程物探勘察设计院有限公司

Agricultural automatic pesticide spray robot

InactiveCN111802358ANo manual movementRealize automatic sprayingShaking/oscillating/vibrating mixersTransportation and packagingAgricultural sciencePesticide residue

The present invention relates to a robot and in particular to an agricultural automatic pesticide spray robot. A technical problem to be solved is to provide an agricultural automatic pesticide sprayrobot capable of automatically shaking a pesticide box, automatically spraying a pesticide and avoiding pesticide residues on a human body. According to a technical solution of the present invention,the agricultural automatic pesticide spray robot includes a frame and a protective cover; the frame is provided with a walking mechanism, and the left and right sides of the frame are provided with hydraulic spray mechanisms connected with the walking mechanism; and the protective cover is disposed at the top of the frame. The walking mechanism drives the agricultural automatic pesticide spray robot to move rightwards, the agricultural automatic pesticide spray robot does not need to be moved manually, in this way, a pesticide may be sprayed on different places; due to the adoption of the hydraulic spray mechanisms, the pesticide is automatically sprayed, repeated manual pressing is not needed, and thus, manual operation is reduced; and the left-right reciprocating motion of a pesticide barrel is realized by a push rod and a first elastic element, and thus, the pesticide may be sufficiently mixed with water so as to be diluted.

Owner:陈永华

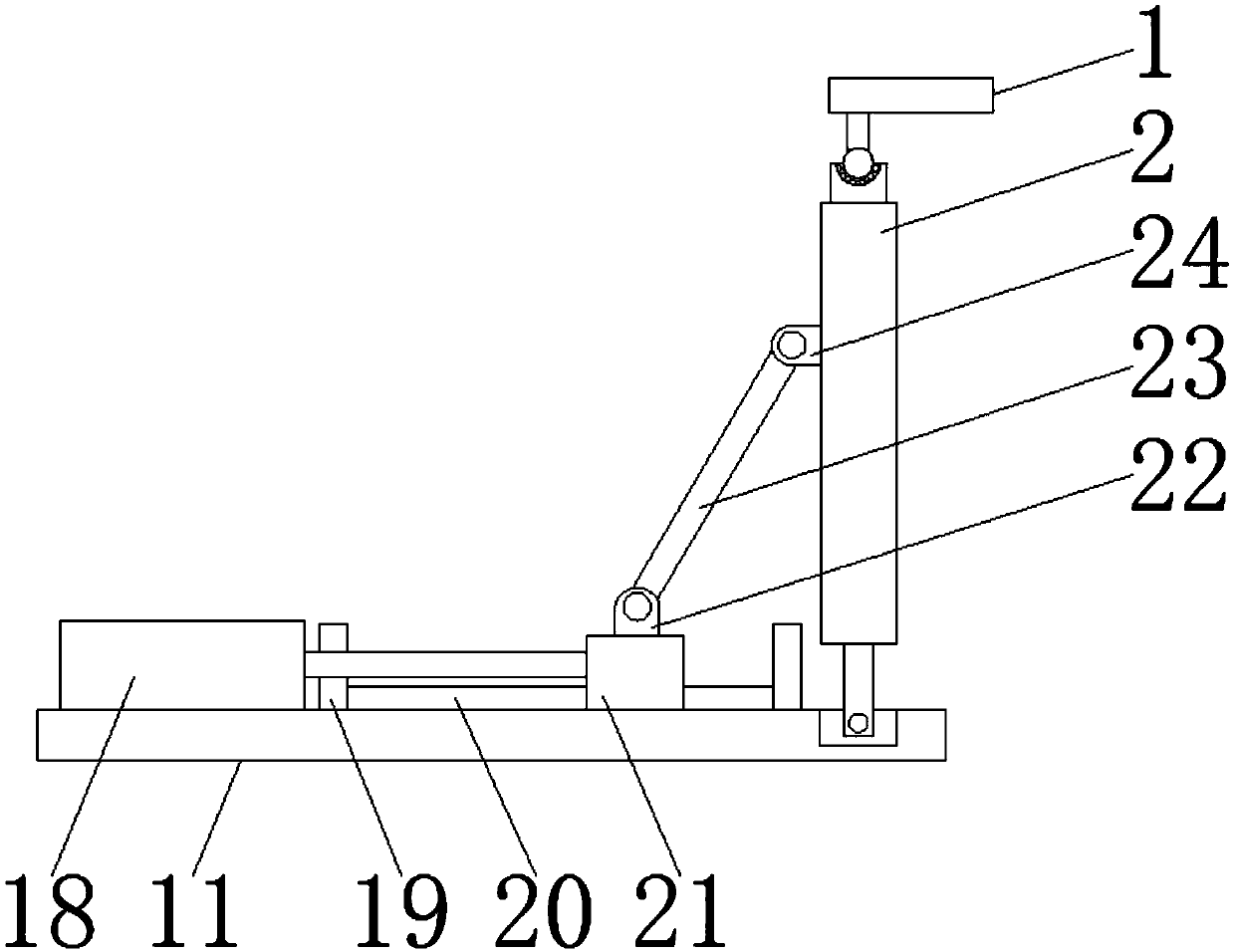

Machine-carried forepoling device

The invention relates to a machine leading support. A support beam is hinge with the top of revolving arm of drill machine; the top part and the support beam are hinged with the lifting connecting rods near the hinge point; another ends of said two lifting connecting rods are hinged; said hinge points are above the revolving arm and the support beam; a lifting hydraulic cylinder is hinged between the hinge point and the revolving arm; the front end of support beam is hinged with a shield beam; the parts of support and shield beam that near the hinge point are hinged with support beam connecting rods; another ends of said two support beam connecting rods are hinged; the hinge points are under the support and shield beam; and the hinge points of said two support beam connecting rods and the support beams are hinged with support beam hydraulic cylinder. The invention can save time, improve efficiency, improve the safety, and simplify the operation.

Owner:山东兖煤黑豹矿业装备有限公司

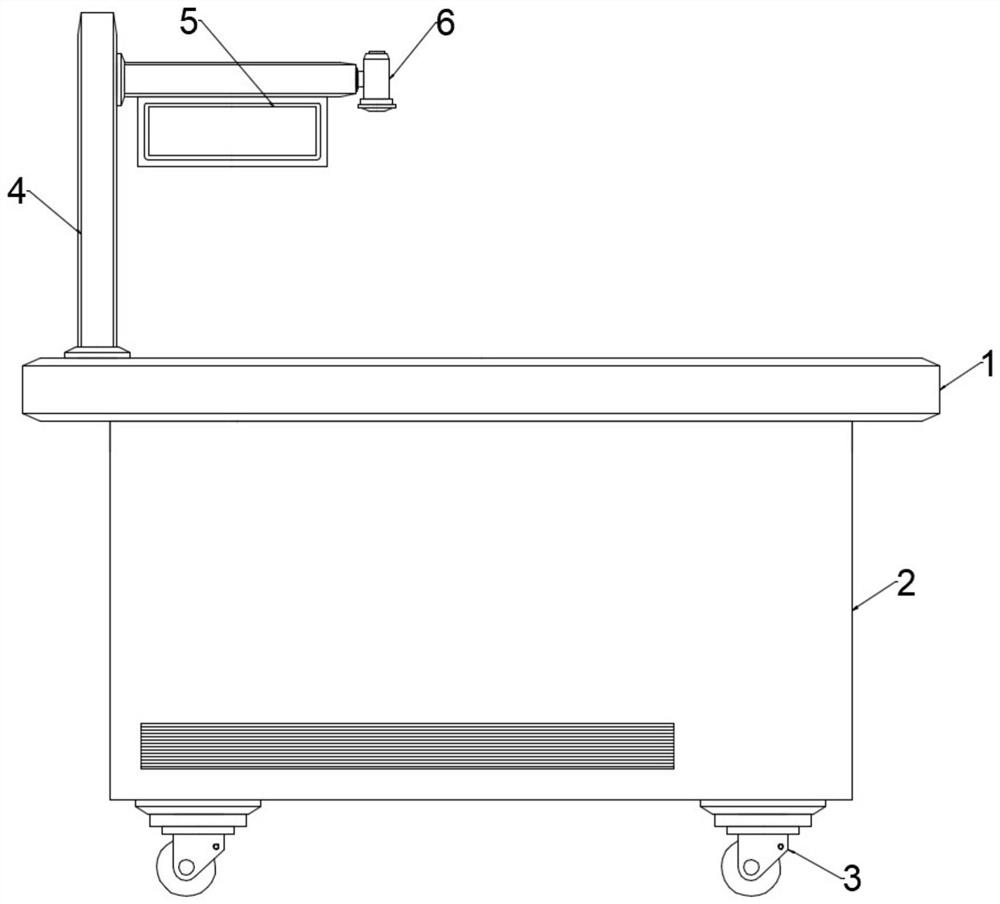

Multifunctional industrial maintenance platform and system thereof

InactiveCN112743495AInnovative designEasy to adjust the positionTelevision system detailsColor television detailsRotary stageIndustrial maintenance

The invention relates to a multifunctional industrial maintenance platform and a system thereof. The multifunctional industrial maintenance platform comprises a workbench and a cabinet body fixed to the lower part of the workbench, wherein a rotating table is embedded into the workbench and connected to a lifting driving mechanism arranged in the cabinet body; the lifting driving mechanism drives the rotating table to move vertically; a rotating driving mechanism is further arranged on the rotating table; the rotating driving mechanism is arranged on the lifting driving mechanism and used for driving the rotating table to do circular motion; a support is further fixed to the workbench; and a display screen and a camera are arranged on the support. The multifunctional industrial maintenance platform and the system thereof are novel in design, lifting adjustment and rotating adjustment of the rotating table are achieved through the arranged lifting driving mechanism and the arranged rotating driving mechanism, so that position adjustment in the product maintenance process is facilitated, manual movement is not needed, the use is convenient, the arranged display screen and camera can be used for remote guidance, the functions are diversified, and the practicability is high.

Owner:NANJING YUSHENG ROBOT CO LTD

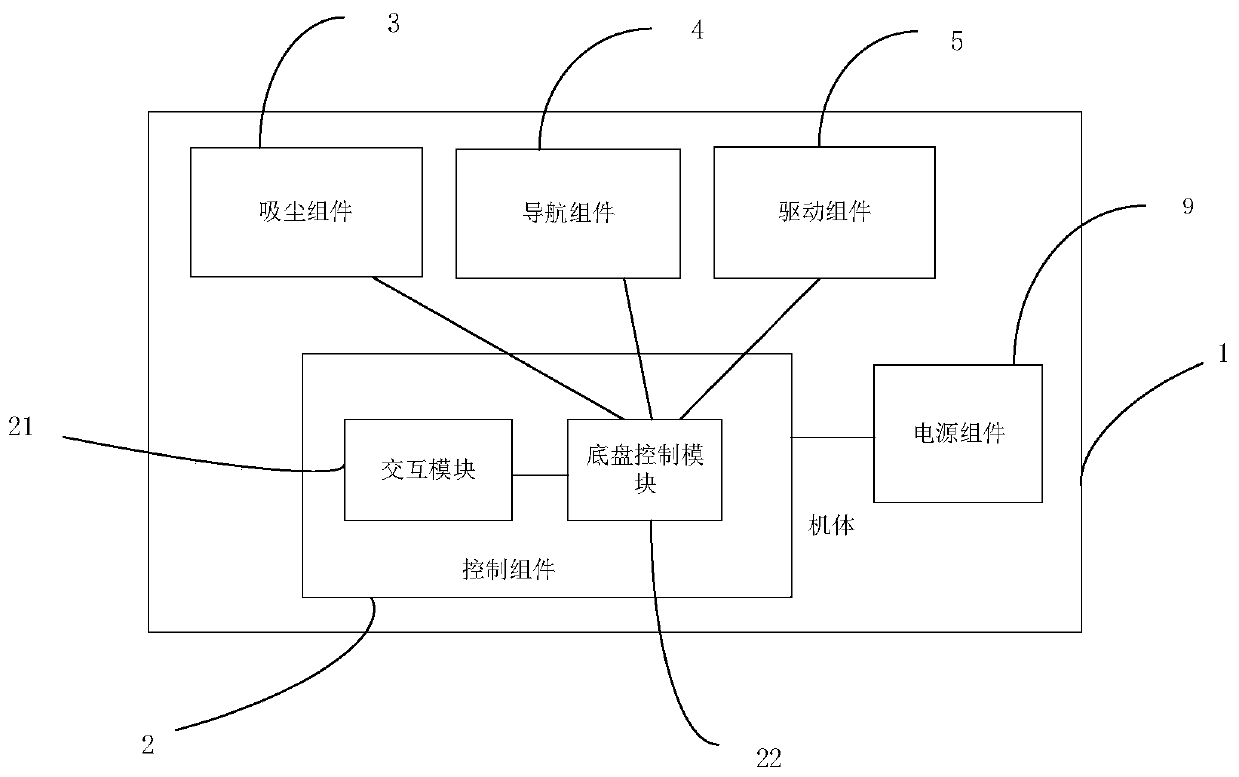

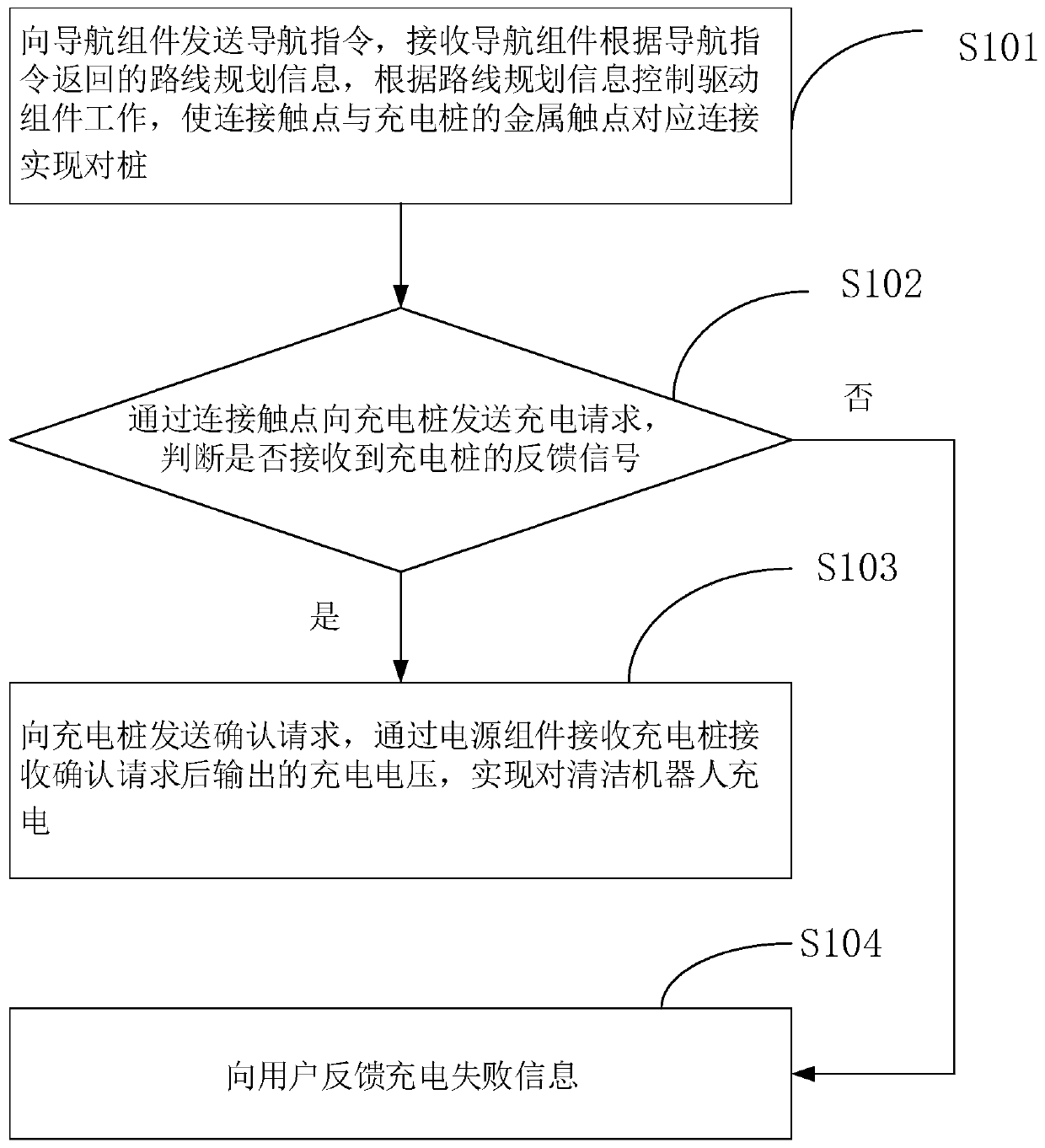

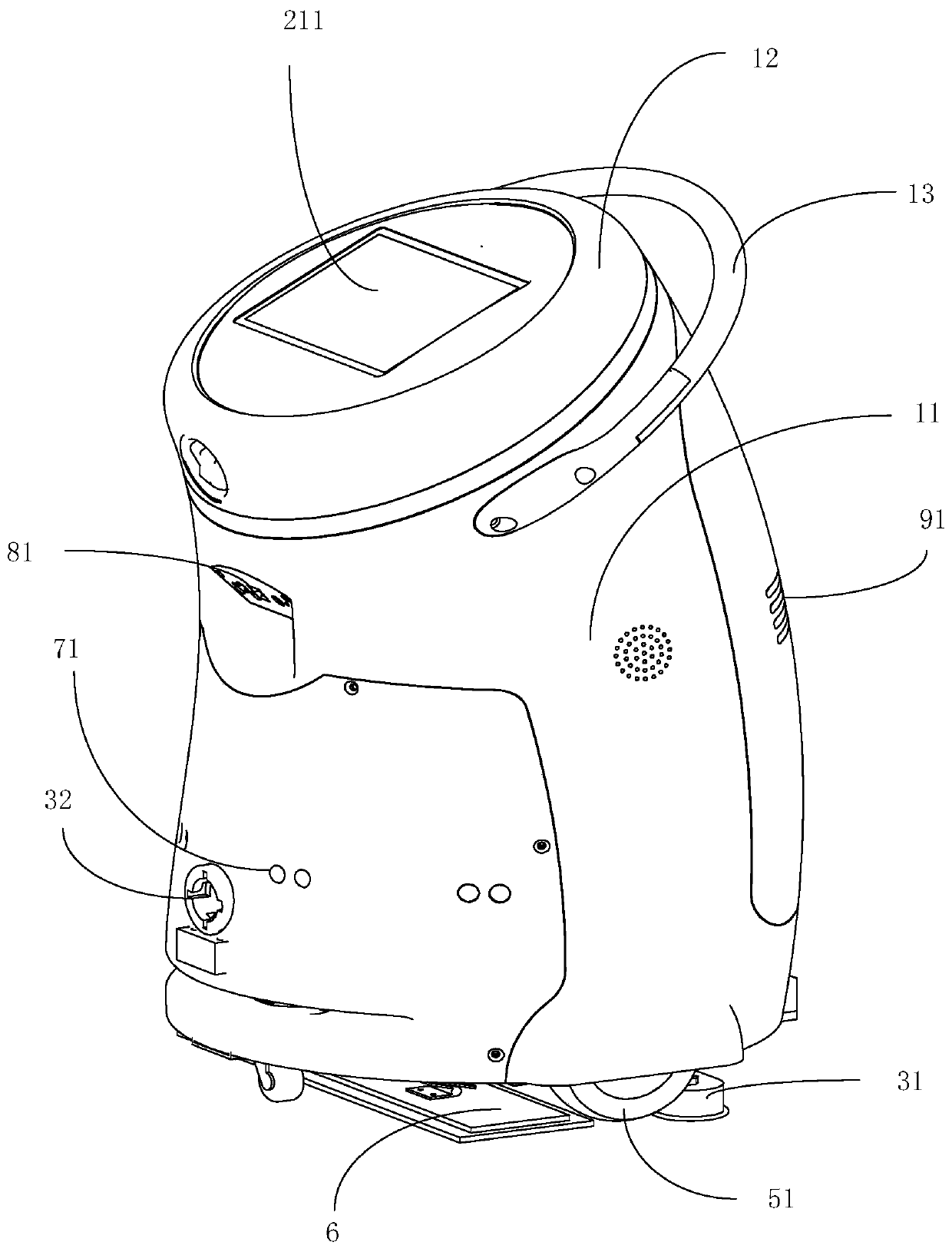

Cleaning robot and automatic charging system

ActiveCN111166230ARealize chargingEliminate disadvantagesAutomatic obstacle detectionTravelling automatic controlControl engineeringElectric shock

The invention provides a cleaning robot and an automatic charging system. A power supply assembly of the cleaning robot comprises a connecting contact. After receiving a charging instruction, a chassis control module executes the following charging method: S101, sending a navigation instruction to a navigation assembly, and controlling a driving assembly to work according to route planning information returned by the navigation assembly so as to enable the connecting contact to be correspondingly connected with the metal contact of a charging pile; S102, sending a charging request the chargingpile, determining whether a feedback signal is received or not, if so, performing S103, and if not, performing S104 is executed; S103, sending a confirmation request to the charging pile, and receiving the charging voltage output by the charging pile through the power supply assembly; and S104, feeding back charging failure information to the user. Manual movement is not needed, the cleaning efficiency is high, the labor cost is reduced, the defects of a power line are overcome; the charging pile supplies power after making contact with the cleaning robot in a mode that the charging request is sent first and then the confirmation request is sent and then charging is conducted, and a problem of electric shock of others is solved.

Owner:锶想(广州)科技有限公司

A wood surface gluing mechanism

ActiveCN111687970BEasy to glueEasy to dipAdhesive application devicesMechanical engineeringEngineering

The invention relates to a gluing mechanism, in particular to a wood surface gluing mechanism. The technical problem of the present invention is to provide a wood surface gluing mechanism that is convenient for the glue brush to pick up the white latex, and does not need to manually pick up the wood repeatedly, and does not need to manually fix the wood. The technical solution of the present invention is: a wood surface gluing mechanism, including: a base on which a support column is installed in a rectangular shape, a processing frame is provided on the top of the support column, and a bar-shaped groove is opened on the rear side of the middle part of the processing frame. The invention can fix the wood through the square groove, and at the same time, through the gluing mechanism, it is convenient for the glue brush to pick up the white latex, which is beneficial to gluing the wood. The automatic cutting of wood does not need to be manually taken repeatedly. Through the winding wheel and the pull rope, the plastic box can be moved up and down during the process of moving the sliding block, without manual movement of the sliding shaft.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

An automatic wall-laying equipment for construction site

ActiveCN111980427BReduce extrusionReduce wasteBuilding material handlingBrickArchitectural engineering

The invention relates to the technical field of construction machinery, in particular to an automatic wall-laying equipment used on a construction site, comprising a base plate and a bearing plate connected to the base plate through a sliding assembly, a working table is arranged on the bearing plate, and a fixed plate There is a brick conveying device on the top, which also includes a clamping device, a first conveying device for conveying concrete to the bottom of the brick, a second conveying device for conveying concrete to the side of the brick, and the first and second driving cylinders. The second cut-off mechanism is equipped with a third drive cylinder on the bottom plate, which also includes a drive mechanism, a detection element, and a controller, which can effectively control the amount of plastering of bricks while realizing automatic wall building and saving labor. After the bricks are placed in the predetermined position, the extrusion amount of concrete is reduced, the labor intensity of workers is reduced, and the waste of concrete is reduced.

Owner:QINGDAO NO 1 CONSTR GRP

Laser radar calibration equipment

PendingCN114280581ANo manual movementAdjustable distanceWave based measurement systemsEngineeringMechanical engineering

The invention discloses laser radar calibration equipment, which comprises a calibration platform, a fixed seat, a movable seat and a driving mechanism, and is characterized in that the fixed seat is fixedly mounted on the calibration platform, the movable seat is movably mounted on the calibration platform, the movable seat has a moving stroke close to and far away from the fixed seat, and the driving mechanism is mounted on the fixed seat. One of the fixed seat and the movable seat is used for installing a laser radar, and the other one is used for installing a detection object; and the driving mechanism drives the movable seat to move for the stroke so as to adjust the detection distance between the laser radar and the detection object. The structure is simple, operation is convenient, and calibration precision is high.

Owner:武汉天眸光电科技有限公司

Automobile production waste identification and cleaning device

InactiveCN112452841AEasy to carryReduce work intensityCleaning using toolsCleaning using liquidsProcess engineeringWaste material

The invention discloses an automobile production waste identification and cleaning device. The automobile production waste identification and cleaning device comprises a conveying device and a slidingconveying plate, wherein a water retaining strip is fixed at the front end of the conveying device, a cleaning brush is arranged at the top end of the interior of the conveying device, the sliding conveying plate is fixedly connected to the lower right portion of the conveying device, an ultrasonic cleaning box is arranged on the lower right portion of the sliding conveying plate, a placing box is arranged inside the ultrasonic cleaning box, a fixing frame is arranged above the placing box, a storage box is fixed on the left side of the ultrasonic cleaning box, and a storage box is arranged on the surface of the storage box. According to the automobile production waste identification and cleaning device, the sliding conveying plate can be used for sliding automobile parts into the ultrasonic cleaning box for further cleaning by utilizing the inclination angle of the sliding conveying plate after the automobile parts are cleaned by the cleaning brush, so that manual movement is not needed, the working intensity of workers is reduced, the placing box can be taken out from the interior of the ultrasonic cleaning box at any time, and therefore the automobile parts can be convenientlytaken out and placed.

Owner:十堰智享科技开发有限公司

A vegetable stem cutting device

ActiveCN111673808BImprove cutting efficiencyNo manual movementMetal working apparatusAgricultural scienceAgricultural engineering

The invention relates to a trimming device, in particular to a device for trimming vegetable stems. The technical problem of the present invention is to provide a device for cutting vegetable stems that can automatically collect cut vegetable stems without manual contact with the cutter and improve operational safety. The technical solution of the present invention is: a device for cutting vegetable stems, including: a base with a rectangular supporting column, a bottom plate is installed on the top of the supporting column; a waste frame, a rectangular hole is opened on the bottom plate, and the rectangular hole is A waste material frame is placed on the base below: a cutting mechanism, a cutting mechanism is arranged on the front side of the bottom plate, and a material dumping mechanism is arranged on the side of the bottom plate. The invention can cut the vegetable stems through the cutting mechanism, which improves the cutting efficiency of the vegetable stems. The cut vegetable stems can be automatically poured into the collection frame through the unloading mechanism. The stalks are collected, and the collection frame can move back and forth, so that the collection frame can hold more vegetable stalks.

Owner:伟龙食品有限公司

A kind of processing technology of blended fabric

The invention discloses a processing technology of a blended fabric. The specific processing process is as follows: cotton fiber, polyester fiber, silver fiber and wool fiber are processed according to the mass ratio of 1:0.6-0.9:0.1-0.2:0.5-0.6 After the fabric obtained after blending and dyeing is rolled into a roll by a rolling machine, the obtained fabric roll is placed on a bearing plate, and the bearing plate is placed on an adaptively adjustable stacking rack for stacking storage. In the present invention, in the process of fabric processing, the obtained fabric roll is directly placed on the self-adaptive adjustable stacking rack, and the elastic bearing mechanism and the lifting and unlocking mechanism are directly cooperated in the stacking process to realize the automatic adjustment of the number of storage layers on the bearing plate containing the fabric. It not only saves manpower, but also can freely adjust the distance between the two carrying boards according to the stacking height of each layer, so as to avoid wasting storage space.

Owner:广东金西湖实业有限公司

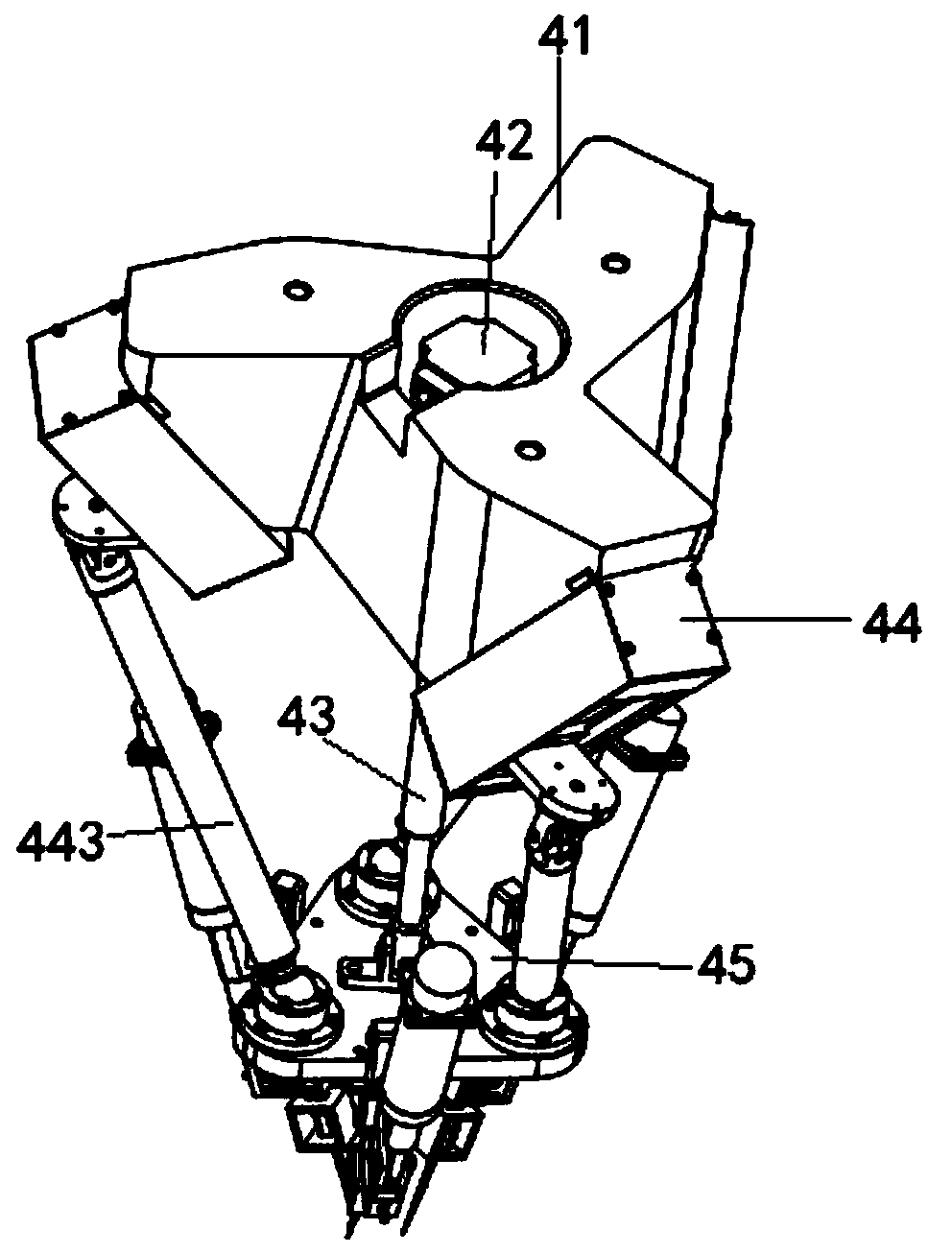

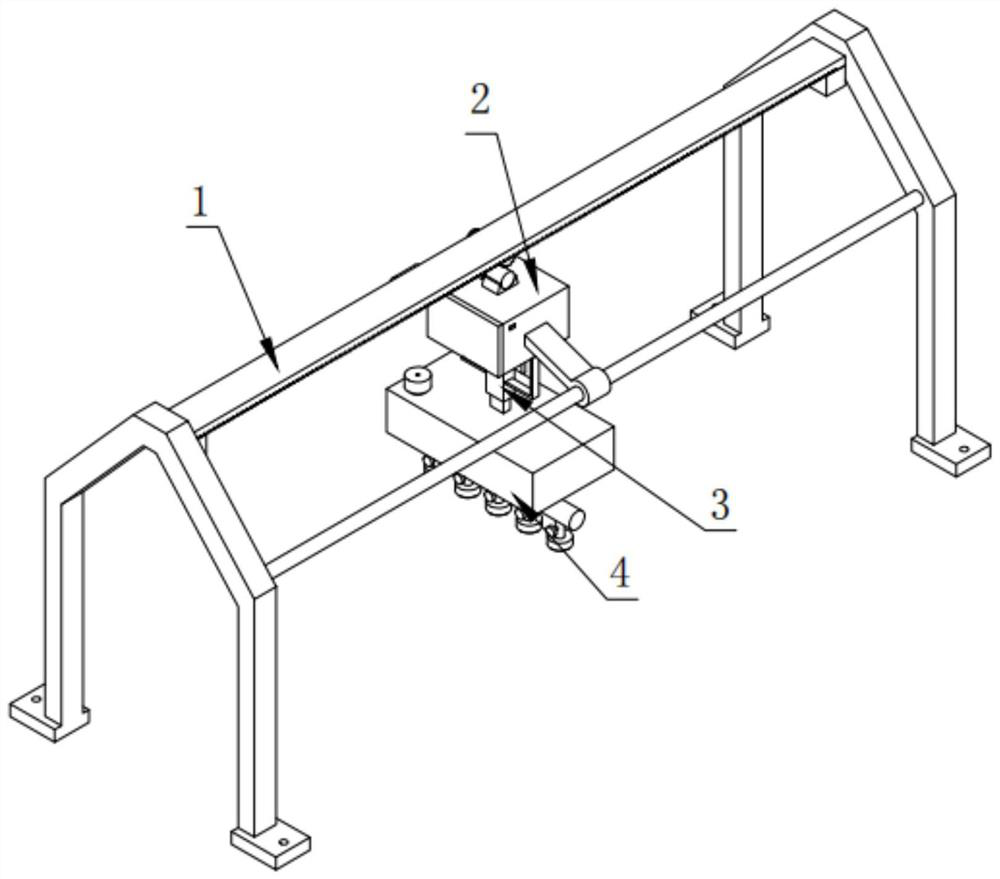

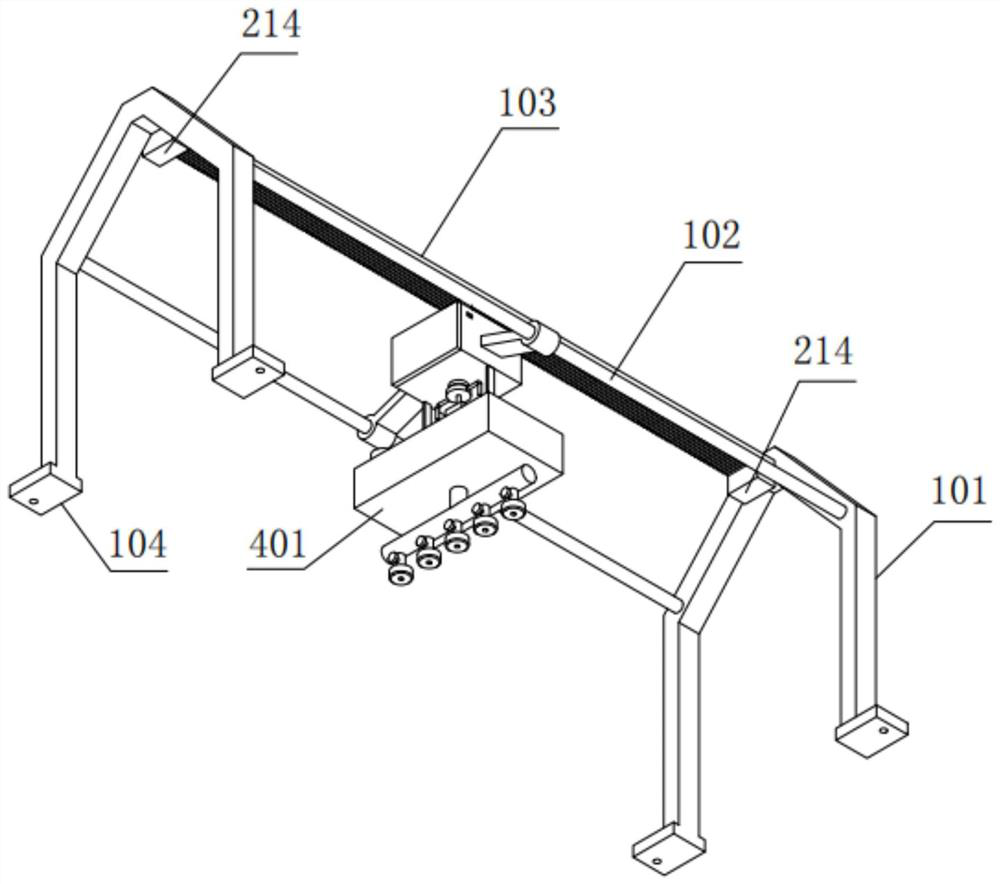

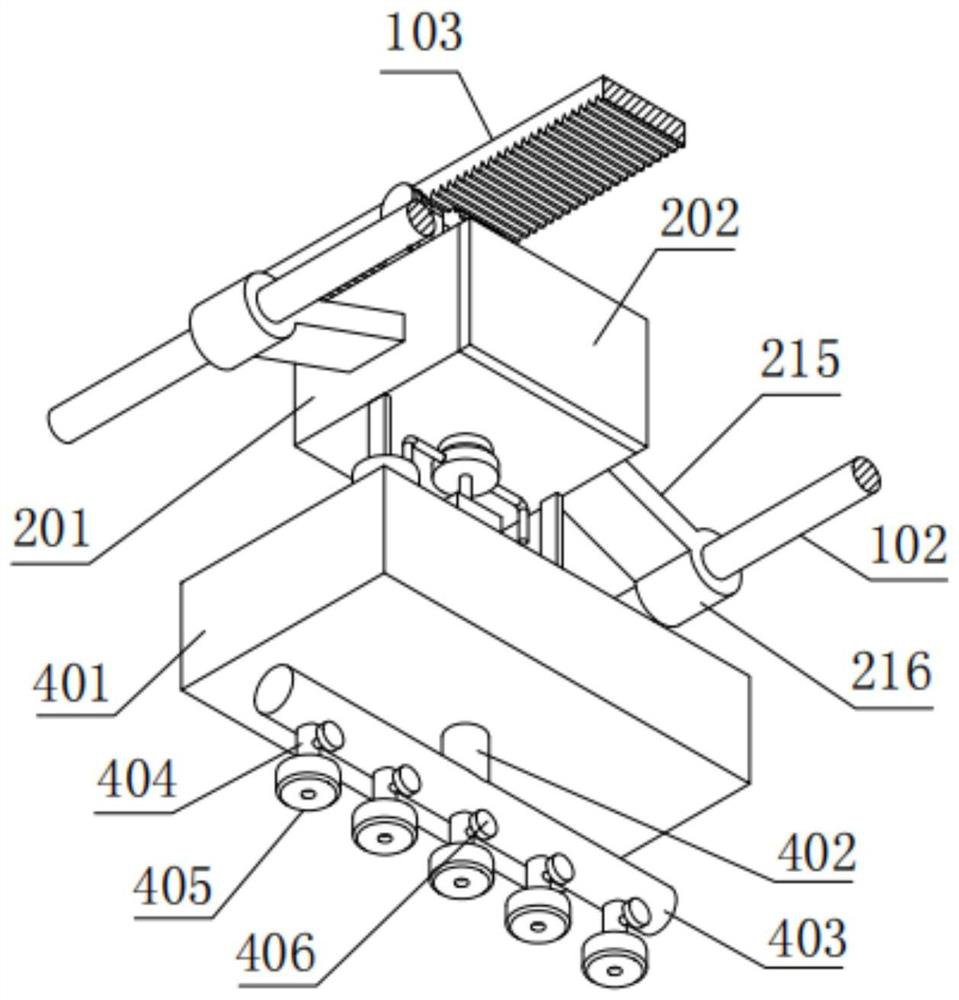

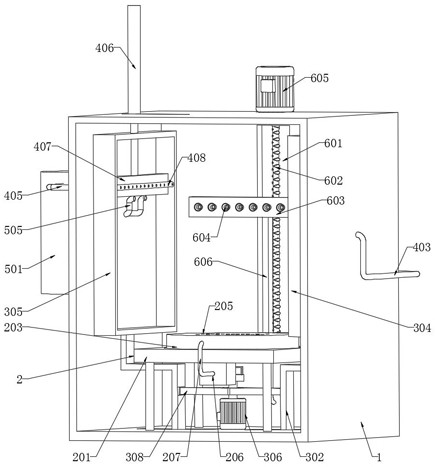

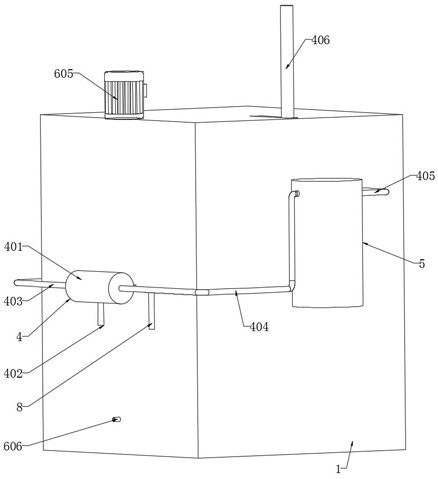

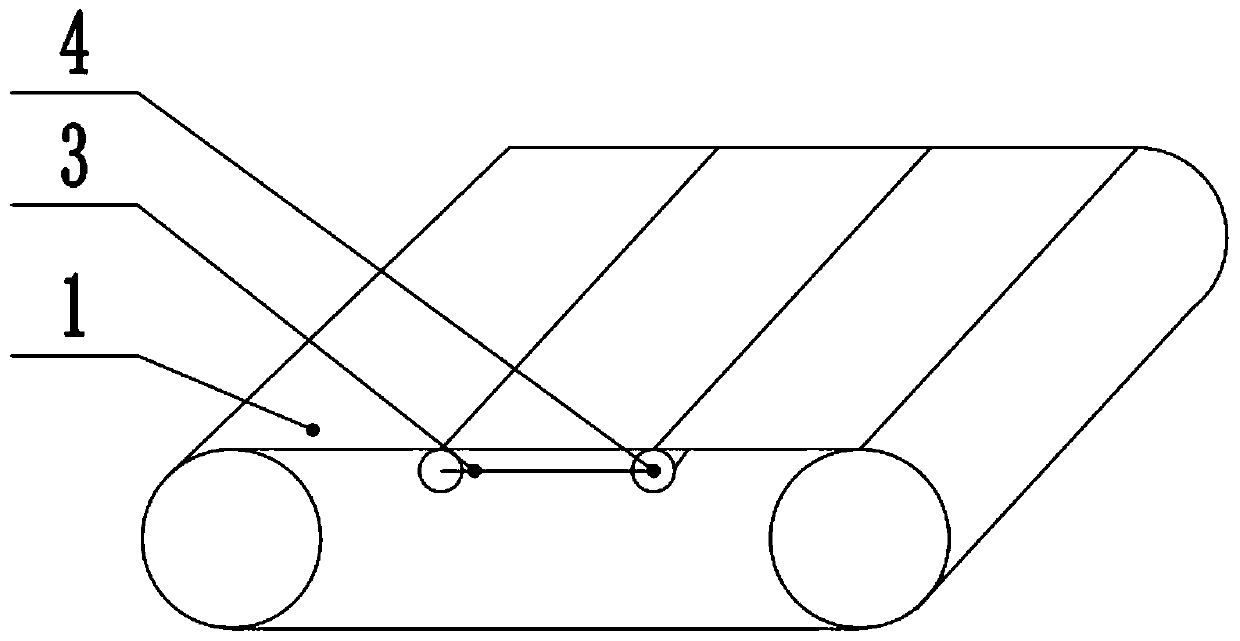

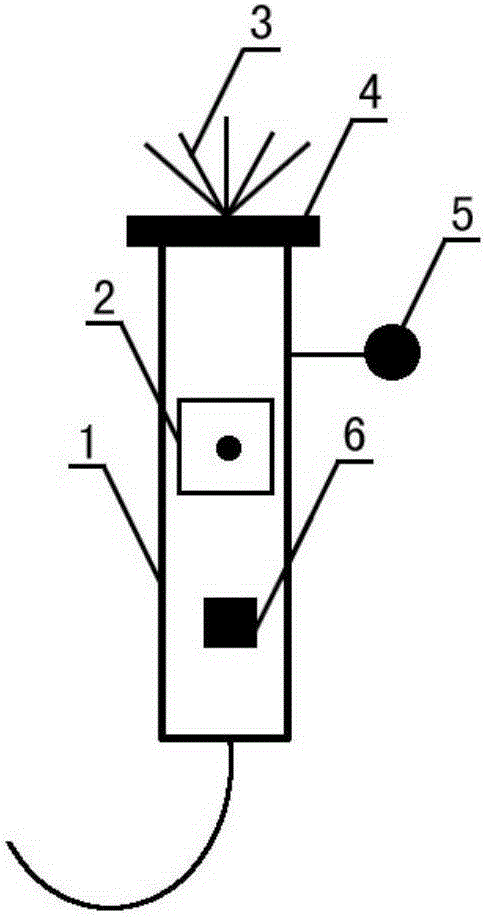

Automatic selective purchasing device for waxberries

InactiveCN105151770AAvoid contaminationIncrease purchase rateConveyor partsRemote controlEngineering

An automatic selective purchasing device for waxberries comprises a rod frame (1). A remote control device (2) is arranged on the rod frame (1), and a grasp device (3) is arranged at the top end of the rod frame. A collecting and releasing assembly (4) is arranged on the grasp device (3). When the waxberries are selected, the rod frame (1) is held by hands, the remote control device (2) is started automatically, the grasp device (3) is used for aligning with the positions of the waxberries to perform intelligent grasping, and the waxberries are collected and released automatically to fall into plastic bags. The positions and the angles of the waxberries on the grasp device (3) can be adjusted. A lighting assembly (5) is arranged on the rod frame and provides auxiliary lighting in the dark environment. A positioning chip (6) is arranged so that the grasp position of the waxberries can be set conveniently, and manual moving is not needed. The rod frame (1) is of a handle structure, so that taking is facilitated. By means of the system, the waxberries can be automatically selected to be put into the bags, two hands are prevented from being tainted with waxberry juice, the use process is safe and sanitary, and the purchase rate of customers is improved.

Owner:ANQING DECHUANG ELECTROMECHANICAL PROD DESIGN

Radiopharmaceutical drug extraction and delivery device for chest tumor examination

InactiveCN109801728AReduce exposureImprove the protective effectPharmaceutical containersMedical packagingRadioactive drugTumor Examination

The invention relates to a radiopharmaceutical drug extraction and delivery device for chest tumor examination. The device comprises a fully enclosed drug extraction operation platform and injection platform, wherein the drug extraction operation platform is provided with a lead can conveying device and drug extraction equipment, the drug extraction operation platform is communicated with the injection platform through a conveying passage and a conveying device, the conveying device is arranged in the conveying passage, the fully enclosed operation platform and injection platform and the conveying passage effectively isolate a radioactive drug from the outside, and the drug extraction operation can be achieved without manual operation through the arrangement of the drug extraction equipment, thereby reducing the contact between a medical worker and the radioactive drug, achieving the protection of the medical worker, improving the protection effect, and reducing the radiation damage ofthe radioactive drug to the medical worker.

Owner:朱登彦

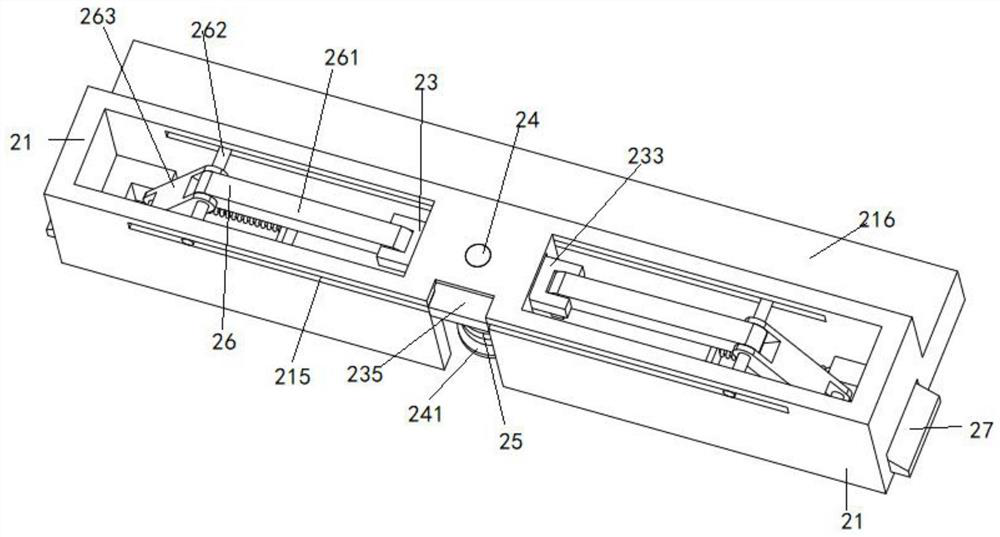

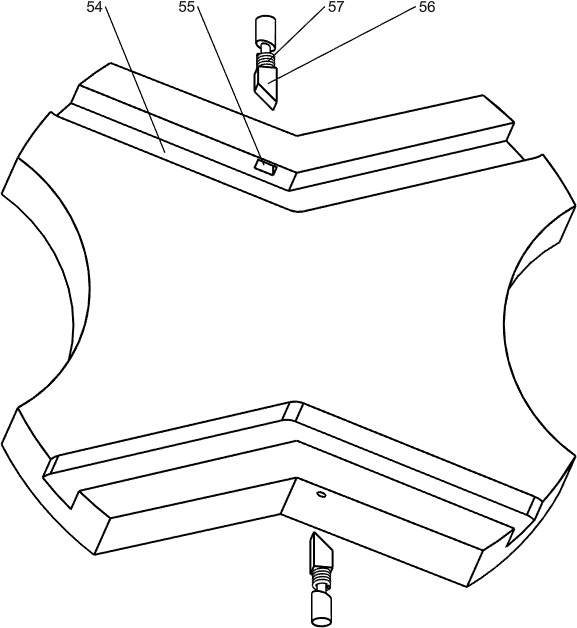

Drilling and screw driving machine for hidden burglar mesh profile

PendingCN112475367ASave human effortStrong quality and efficiencyMetal working apparatusBoring/drilling machinesElectric machineryEngineering

The invention discloses a drilling and screw driving machine for a hidden burglar mesh profile. The drilling and screw driving machine comprises an equipment bin body, a screw driving and speed reducing integrated machine and a material bearing bin, a first driving push rod is installed above the equipment bin body, the front end face of the first driving push rod is connected with a drilling andspeed reducing integrated machine, a stepping motor is arranged in front of the equipment bin body, a limiting baffle is arranged on the right side of the stepping motor, a lead screw transmission table is installed on the right side of the limiting baffle, the screw driving and speed reducing integrated machine is installed on the right side of the drilling and speed reducing integrated machine,a screw bearing body is installed on the lower end face of the screw driving and speed reducing integrated machine, and an equipment room is arranged in front of the lead screw transmission table. According to the drilling and screw driving machine, a full-automatic mechanism structure is adopted on the whole, drilling and screw driving operation on long-strip-shaped aluminum profiles is carried out to replace traditional manual operation, manpower is greatly saved, high working quality and working efficiency are achieved, and only one person is needed for watching over and being responsible for feeding and discharging with easiness.

Owner:广州市瑞搏特自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com