Processing technology of blended fabric

A processing technology and technology of blended fabrics, which are applied in the direction of unloading device, destacking of objects, stacking of objects, etc., can solve the problems of inconvenient storage, waste of manpower, easy moisture absorption of fabrics, etc., to save manpower and avoid waste. The effect of storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A kind of processing technology of blended fabric, concrete processing process is as follows:

[0038] Cotton fiber, polyester fiber, silver fiber and wool fiber are blended and dyed according to the mass ratio of 1:0.8:0.15:0.53, and the fabric obtained is rolled into a roll by a cloth winding machine, and the obtained fabric roll is placed on a load-bearing board, and place the loading board on the self-adaptive adjustable stacking frame for stacking storage;

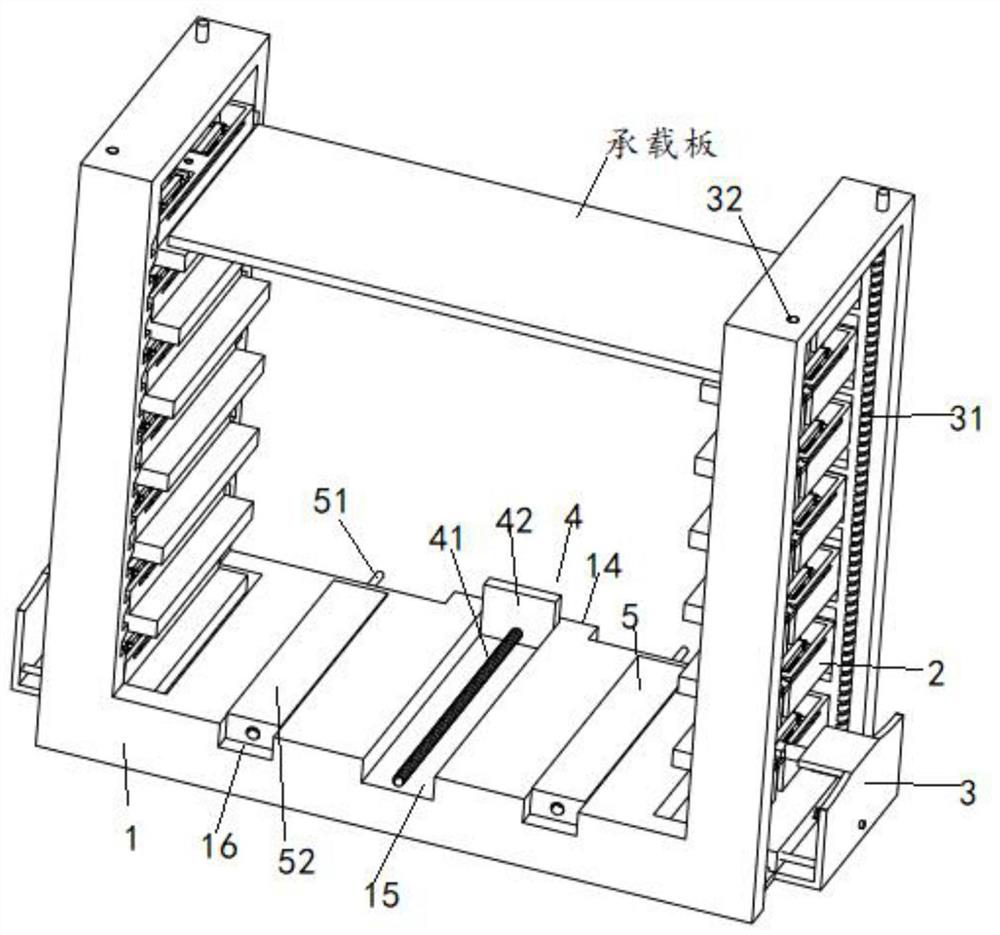

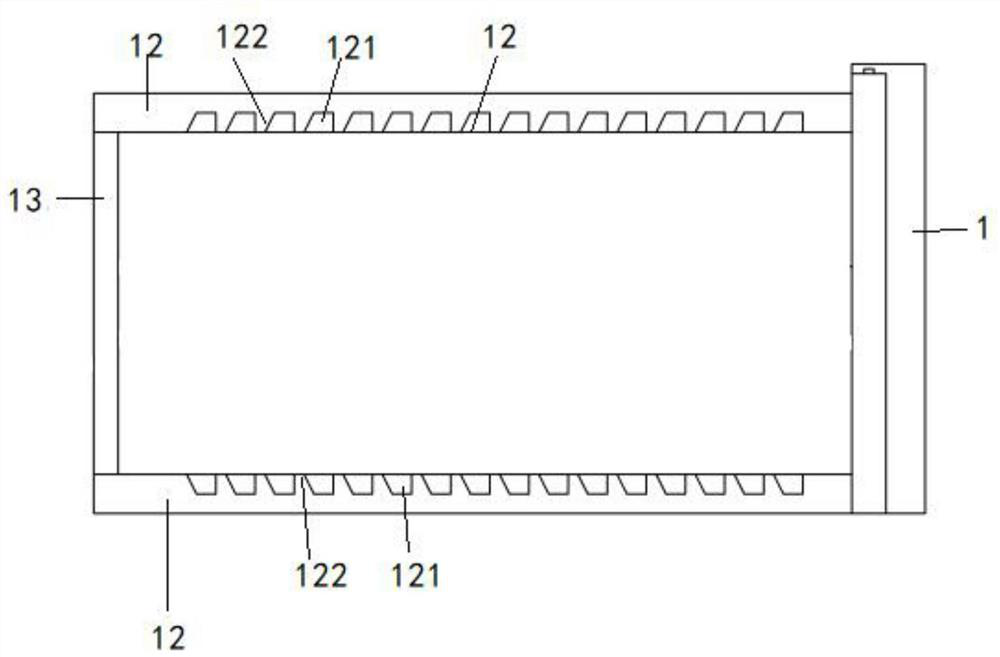

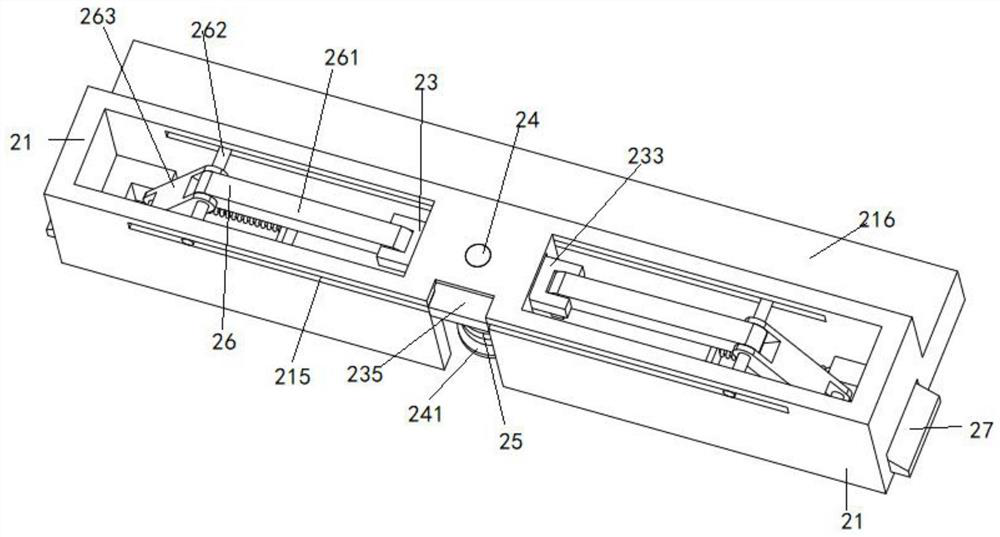

[0039] like Figure 1-7 As shown, the self-adaptive adjustable stacking frame includes a base plate 1, and the middle part of both sides of the surface of the base plate 1 is provided with a first placement hole 11 extending to both sides. Support rods 12, the first installation bar 13 is vertically connected and fixed between the top surfaces of the two support rods 12, the elastic bearing mechanism 2 is installed between the two support rods 12, and the lifting unlocking mechanism 3 is installed on the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com