Gas pipe fitting automatic welding device

A technology for automatic welding and gas pipes, applied in auxiliary devices, welding accessories, welding equipment, etc., can solve problems such as narrow welding positions, failure to meet product quality, unstable quality, etc., to ensure welding quality, save labor costs, The effect of high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings, and specific implementation methods will be given.

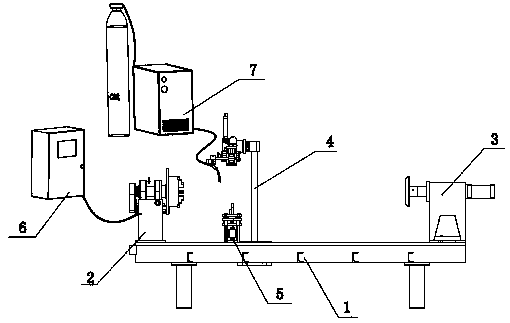

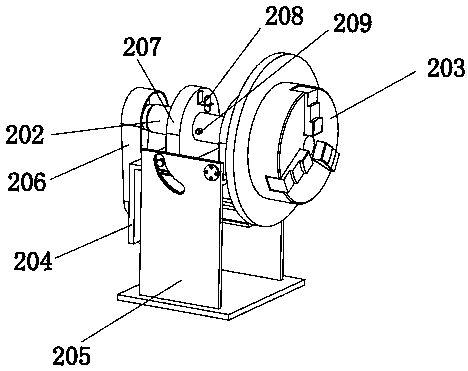

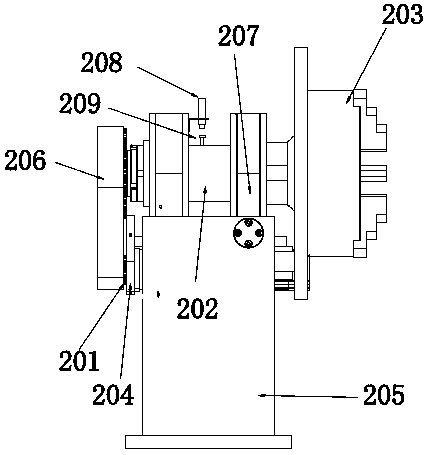

[0021] Such as figure 1 As shown, an automatic welding device for gas pipe fittings of the present invention includes a base 1, one end of the base 1 is the power end, the other end of the base 1 is the tail end, and the power end is equipped with a power head assembly 2 for fixing the welding end of the gas pipe fittings 1. The upper surface of the base 1 is provided with a slide rail, and the tail end is installed with a tailstock assembly 3 for tightening the other end of the gas pipe. The bottom of the tailstock assembly 3 is controlled by the tailstock cylinder to slide on the slide rail, and the air pressure As power, it is used to feed forward and press the steel ring to the metal pipe. The control switch of the tailstock cylinder is set on the ground for easy operation by stepping on it; There is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com