Machine-carried forepoling device

A technology of advanced support and support beam, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of reducing the time of excavation, the inability to effectively protect the roof, and the long time of supporting operation, so as to reduce the number of operators. Quantity, the effect of reducing personal accidents and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

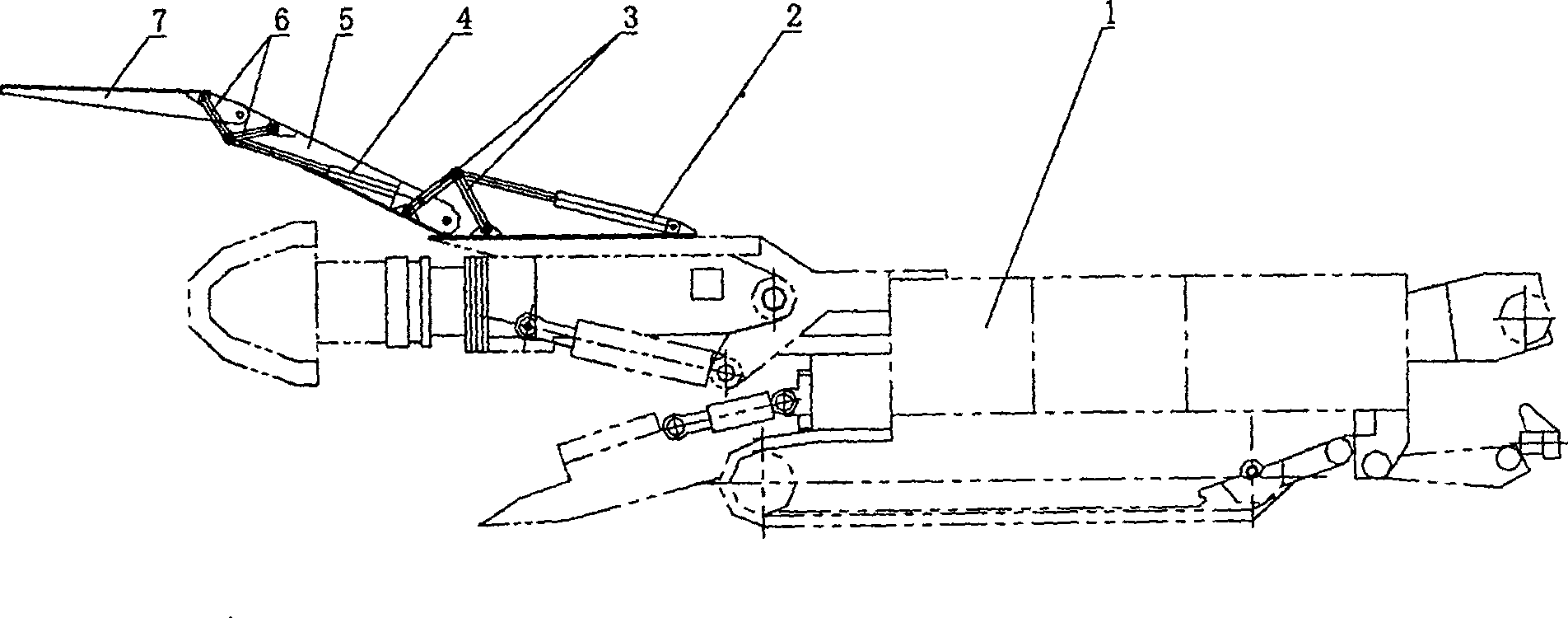

[0008] With reference to accompanying drawing, this airborne advanced support device is made of supporting beam 5, shielding beam 7, lifting beam hydraulic cylinder 2, supporting beam hydraulic cylinder 4, lifting beam connecting rod 3 and supporting beam connecting rod 6. The supporting beam 5 is articulated by pins at the top of the slewing arm of the fully-mechanized excavator 1, and the lifting beam connecting rod 3 is respectively hinged on the top of the slewing arm of the fully-mechanized excavating machine 1 and the supporting beam 5 near the hinge point, and the other ends of the two lifting beam connecting rods 3 are respectively hinged. Hinged, the hinge point is above the slewing arm of the fully mechanized excavator 1 and the support beam 5, and the lifting beam hydraulic cylinder 2 is hinged between the hinge point of the two lifting beam connecting rods 3 and the slewing arm of the fully mechanized excavator 1; the front end of the support beam 5 is pinned The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com