Girder transporting vehicle, girder transporting system, steel box girder assembling system and steel box girder assembling methods

An assembly system and steel box girder technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of small size of module vehicles, large bearing capacity, and difficult control of installation accuracy, so as to achieve stable and reliable beam transportation, The effect of large carrying capacity and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

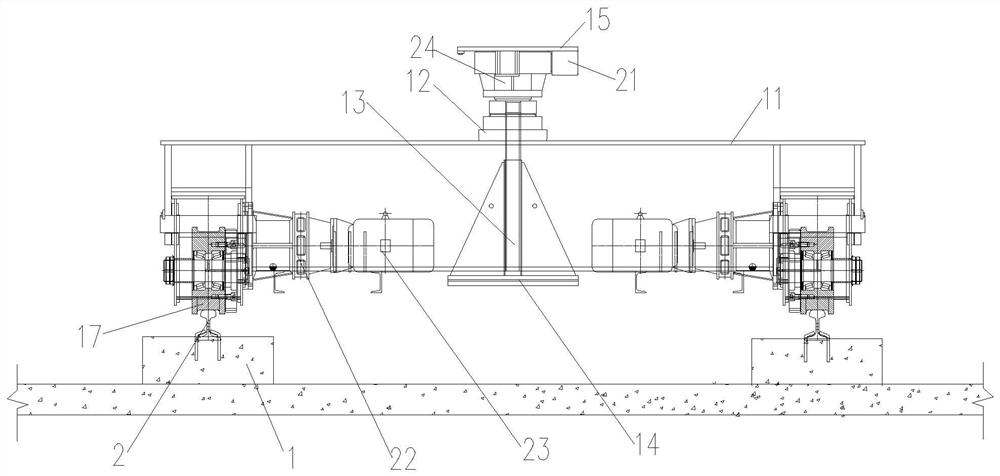

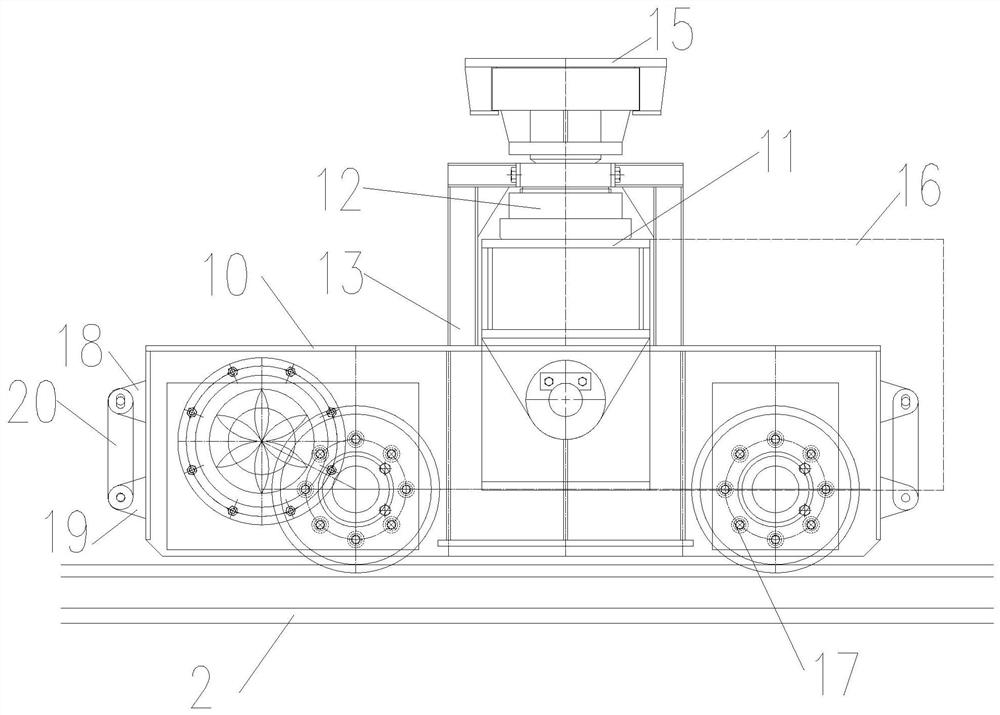

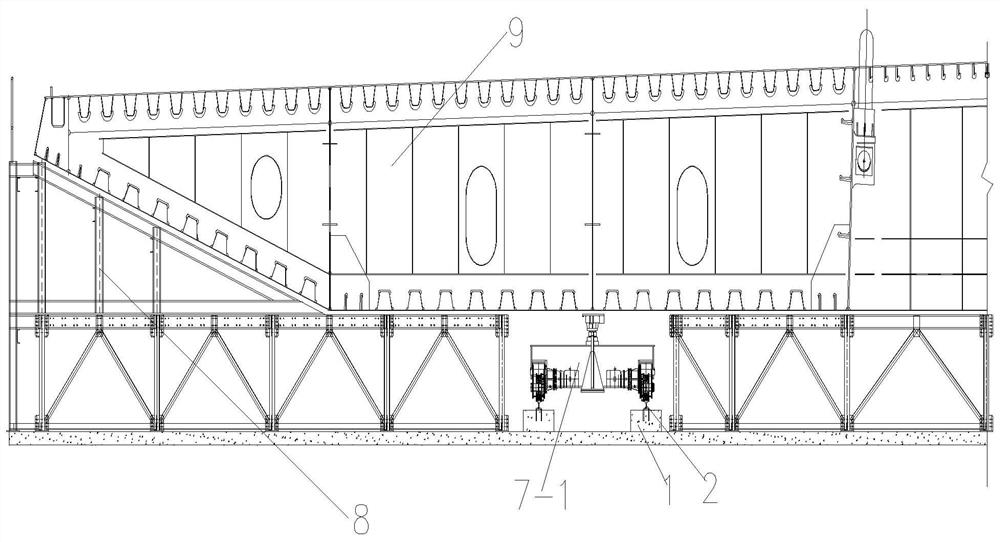

[0087] like figure 1 and image 3 As shown, a beam transport vehicle according to the present invention includes two carriages 10 and a balance box girder 11 connecting the two carriages 10, the front and rear ends of the bottom of the carriage 10 are provided with a The walking wheel 17 that the beam foundation track 2 moves, the carriage 10 is provided with a speed reducer 22 that controls the rotation of the road wheel 17 and a drive motor 23 that cooperates with the speed reducer 22, and the middle part of the balance box girder 11 is provided with a top plate extending from the balance box girder 11. The owner’s jack 12 for transporting the beam, the jack 12 for the owner of the beam transporting is fixedly installed with a top bracket 24, and a top cap 15 is placed on the top bracket 24, and a plurality of pressure sensors and position sensors are arranged in the top cap 15, and a bottom of the top cap 15 The side is provided with the auxiliary jack 21 of the beam trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com