Ecological soil remediation equipment

A technology of ecological soil and equipment, applied in the field of soil remediation, can solve the problems of inability to use centrifugal force and easy soil adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

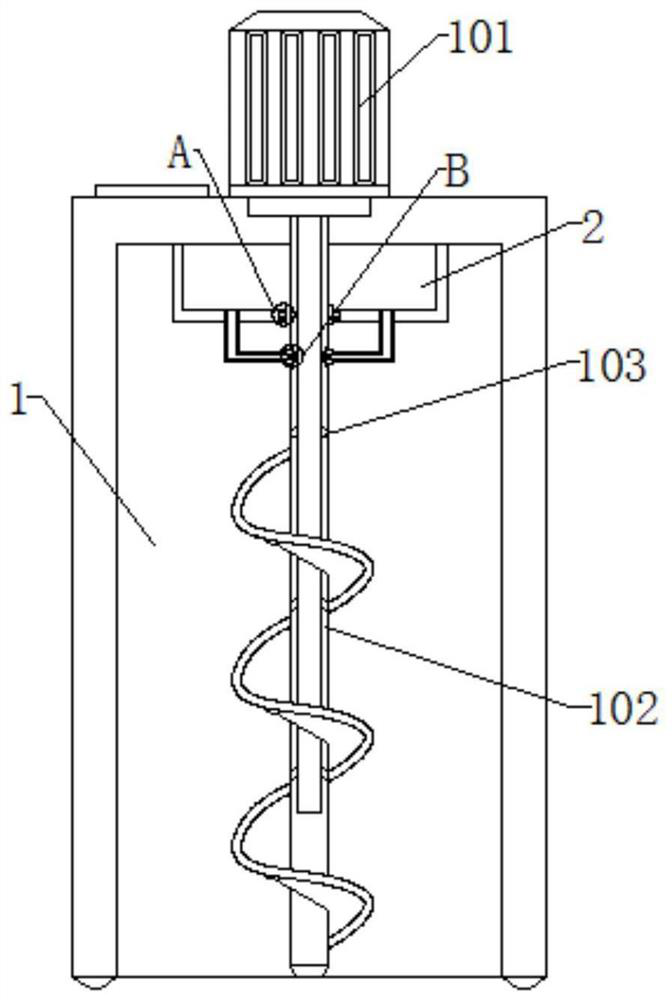

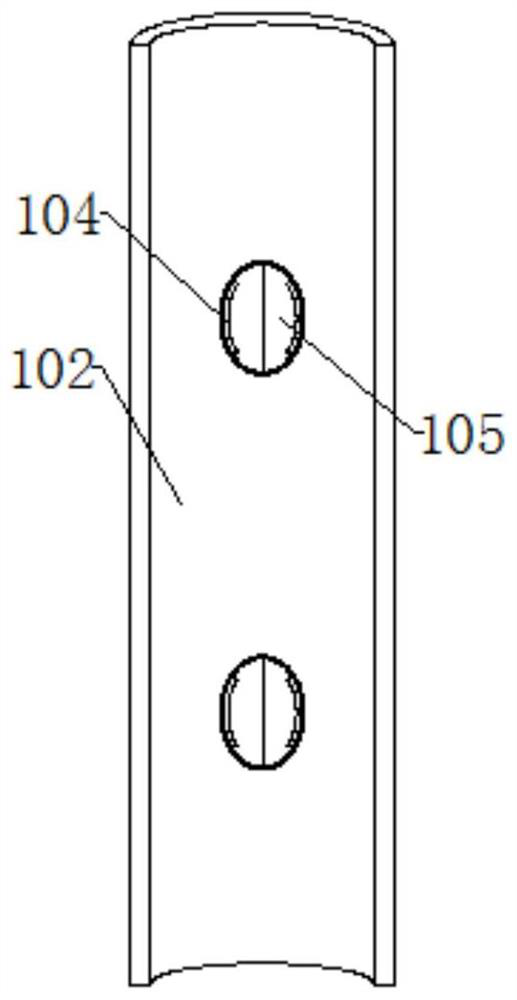

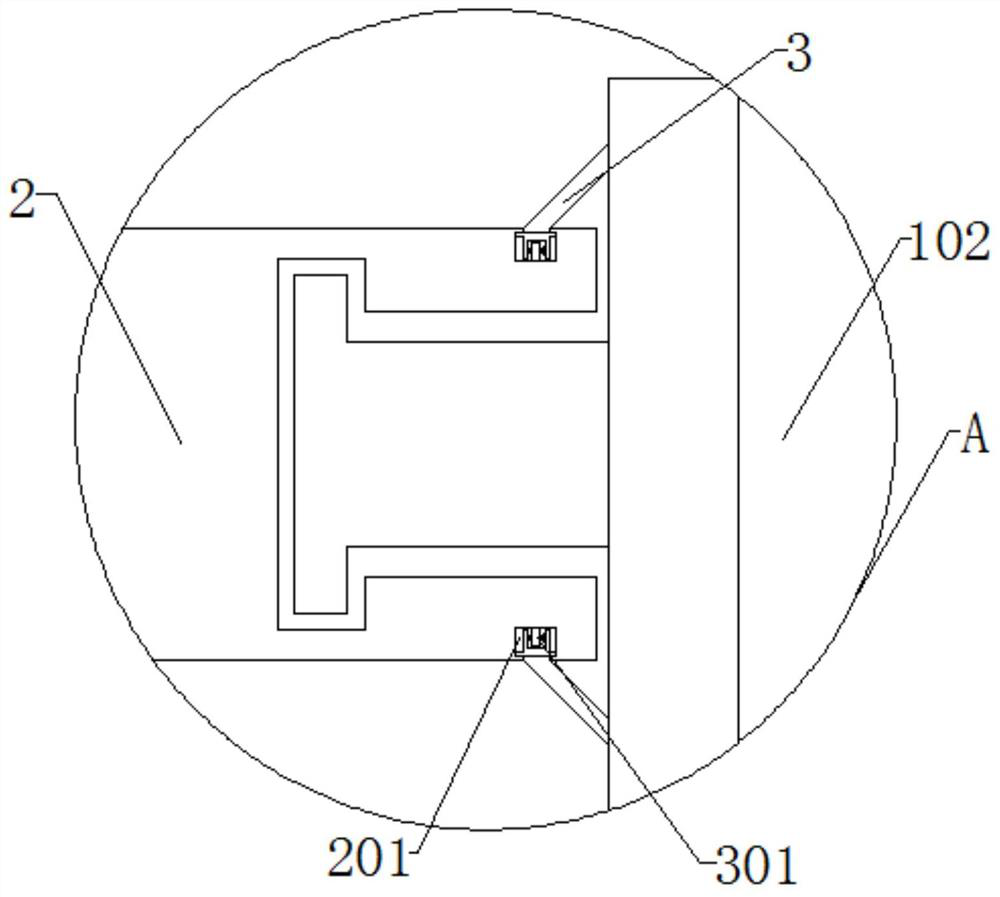

[0032] Embodiment 1: a motor 101 is installed on the upper end of the device main body 1, an auger 102 is rotated at the lower end of the motor 101, and a liquid outlet 103 is rotated outside the lower end of the auger 102, and hinges 104 are hinged on both sides inside the liquid outlet 103, One side of the hinge 104 swings with a sealing plate 105, the upper end of the device main body 1 is equipped with a liquid storage box 2, the inner side of the liquid storage box 2 is embedded with an inner cavity 201, the lower end of the liquid storage box 2 runs through a pipe 202, and the hinge dragon 102 A snap ring 3 is installed near the outer side of the liquid storage box 2, and a roller 301 rotates on the inner side of the snap ring 3. The motor 101 is electrically connected to the power supply through a power cord. The plate 105 and the hinge 104 swing at 90°, while the block 3 rotates at 360° inside the cavity 201, the snap ring 3 is arranged in a funnel shape, and the sealin...

Embodiment 2

[0034]Embodiment 2: a motor 101 is installed on the upper end of the device main body 1, an auger 102 is rotated at the lower end of the motor 101, and a liquid outlet 103 is rotated outside the lower end of the auger 102, and hinges 104 are hinged on both sides inside the liquid outlet 103, One side of the hinge 104 swings with a sealing plate 105, the upper end of the device main body 1 is equipped with a liquid storage box 2, the inner side of the liquid storage box 2 is embedded with an inner cavity 201, the lower end of the liquid storage box 2 runs through a pipe 202, and the hinge dragon 102 A snap ring 3 is installed near the outer side of the liquid storage box 2, and a roller 301 is rotated on the inner side of the snap ring 3. The side of the auger 102 close to the pipe 202 is hinged with a swivel bearing 4, and one end of the swivel bearing 4 swings with a baffle 401. The other side of the bearing 4 swings with a swing frame 402, the two sides of the swing frame 402...

Embodiment 3

[0036] Embodiment 3: The side of the auger 102 close to the pipeline 202 is hinged with a swivel bearing 4, one end of the swivel bearing 4 swings with a baffle 401, and the other side of the swivel bearing 4 swings with a swing frame 402, and the two sides of the swing frame 402 rotate There is a first bearing 403, a shaft arm 404 swings on one side of the first bearing 403, a second bearing 405 is hinged on the inner side of the shaft arm 404, a fixed bearing 406 is movably nested on the side of the shaft arm 404 away from the swing frame 402, and the pipe 202 is installed near the end of the baffle plate 401 with a fixed frame 5, one end of the fixed frame 5 swings with a third bearing 501, the side of the third bearing 501 close to the baffle plate 401 swings with a bracket 502, and the other side of the third bearing 501 swings There is a drive frame 503, and the side of the drive frame 503 close to the auger 102 is embedded with a slide rail 504, and a sleeve 6 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com