Rare earth-containing heat-resistant alloy steel and slab continuous casting process thereof

A technology of slab continuous casting and alloy steel, which is applied in the field of metal materials and its manufacture, can solve problems such as inclusions and cracks in continuous casting slabs, achieve good center quality, improve the surface and center quality of slabs, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

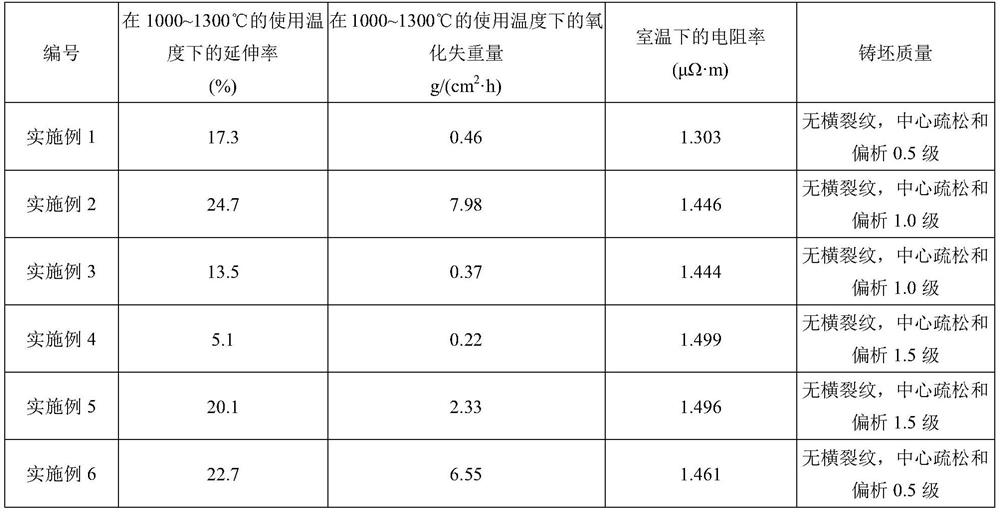

Examples

Embodiment 1-6

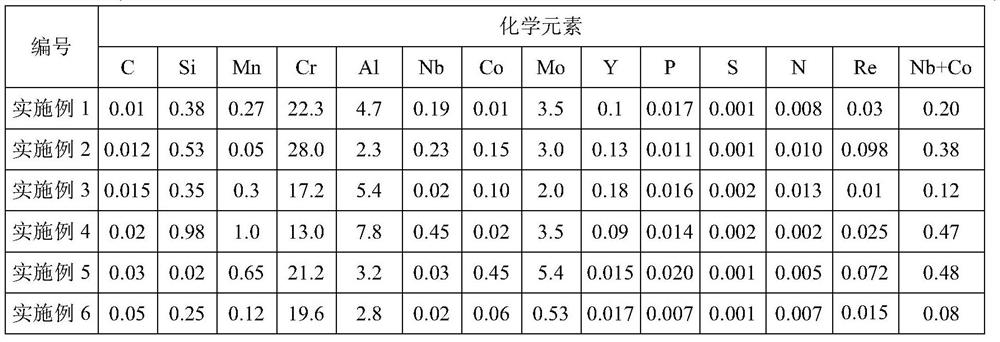

[0072] Table 1 lists the mass percentage of each chemical element in the rare earth-containing heat-resistant alloy steel of Examples 1-6.

[0073] Table 1. (wt%, the balance is Fe and other unavoidable impurities except P, S, N)

[0074]

[0075] It should be noted that Re in Examples 1-6 in Table 1 represents the mass percentage of any one or several elements of No. 57 to No. 71 in the periodic table of chemical elements.

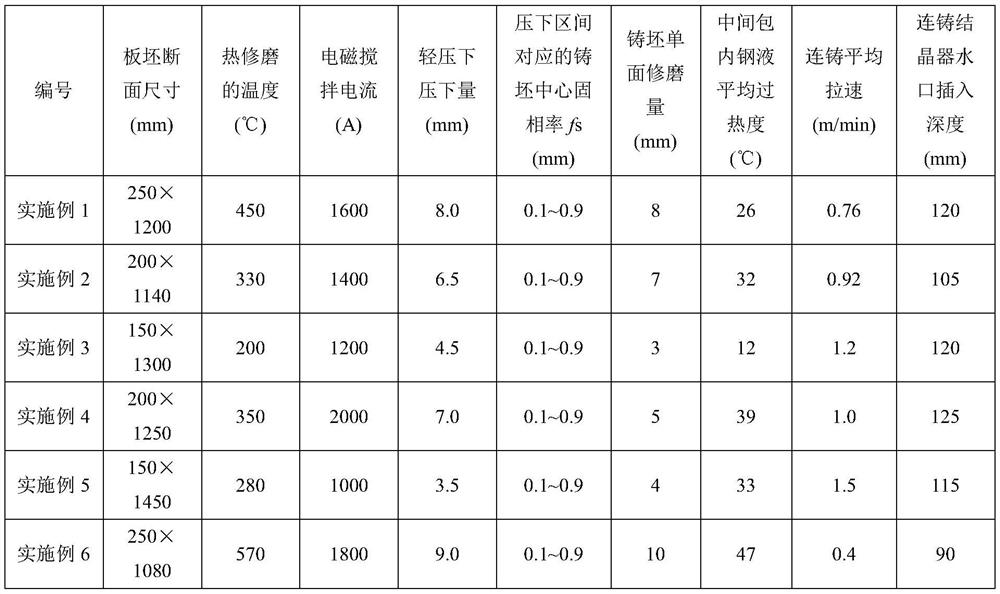

[0076] The rare earth-containing heat-resistant alloy steels of Examples 1-6 of the present invention are all produced by the following continuous casting production process:

[0077]In the continuous casting process, the water ratio of the secondary cooling water is controlled to be 1.02±0.10L / kg, the temperature of the hot grinding of the slab is controlled to be 100-600°C, the electromagnetic stirring current is controlled to be 1000-2000A, and the reduction amount of the light reduction is controlled to be 3-10mm, the solid phase ratio fs of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com