A kind of gradient structure metal type c/c composite material and its preparation method and application

A composite material, gradient structure technology, used in transportation and packaging, electric vehicles, current collectors, etc., can solve the problems of heavy weight and large wire wear, and achieve the effect of low bonding resistance, low resistivity, and reducing adhesive wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

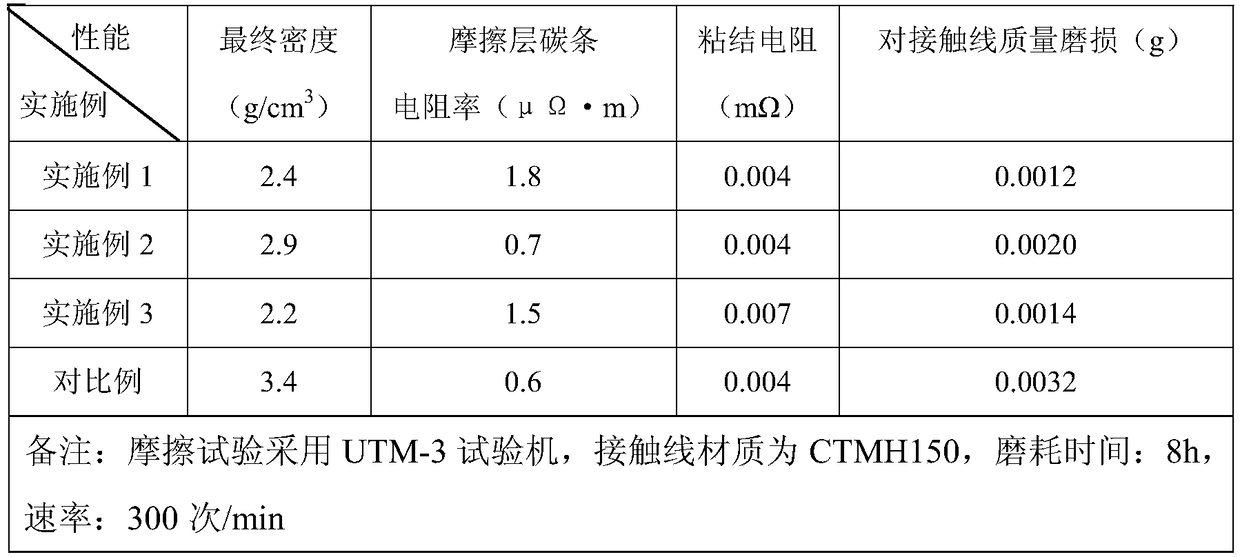

[0041] Using a felt body with a mass content of 94% copper in the bonding layer and a mass content of 20% copper in the friction layer as a prefabricated body, a composite material with a residual porosity of 15% was prepared by a chemical vapor deposition process, and two resin impregnation-carbonization process, prepared an average density of 2.4g / cm 3 Gradient metal type C / C slider.

[0042] Specific steps are as follows:

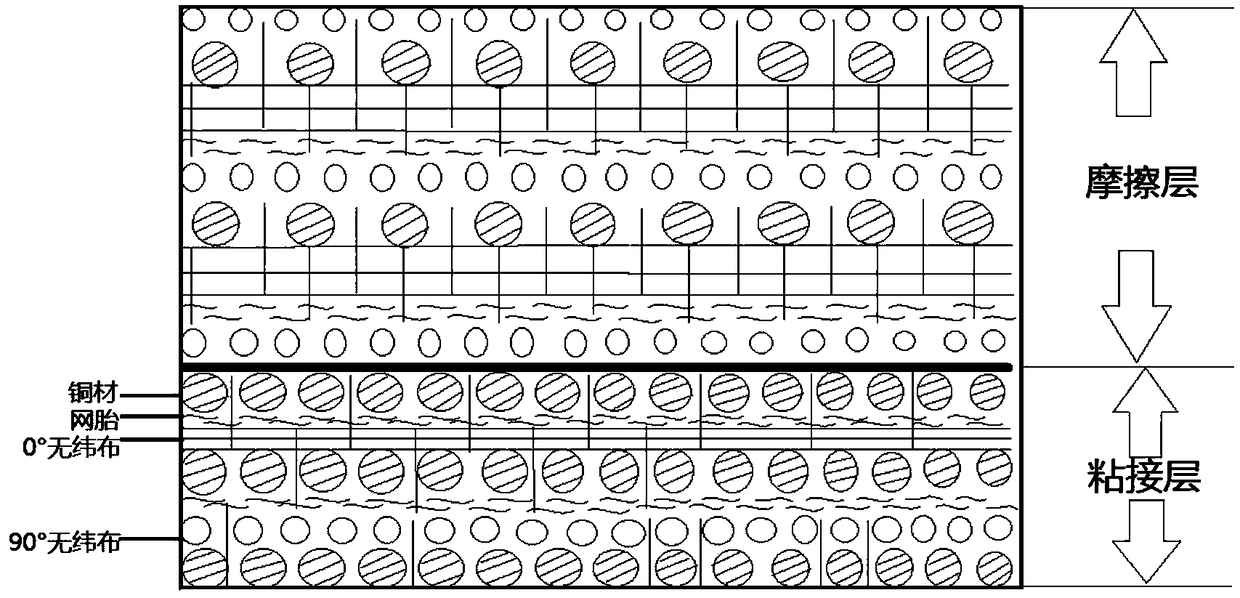

[0043](1) The carbon fiber prefabricated body consists of two parts, the adhesive layer and the friction layer, which are connected into one body by needle punching. The bonding layer is composed of 0° latitude-free carbon cloth, carbon fiber mesh tire, copper mesh, 90° latitude-free carbon cloth, carbon fiber mesh tire, copper powder, and 0° latitude-free carbon cloth. The quality of copper mesh and copper powder are respectively Accounting for 74% and 20% of the total mass of the bonding layer; the friction layer is composed of 0° latitude carbon clo...

Embodiment 2

[0047] Using a felt body with a mass content of 90% copper in the bonding layer and a mass content of 82% copper in the friction layer as the prefabricated body, a composite material with a residual porosity of 12% was prepared by chemical vapor deposition, and the composite material was prepared by two resin impregnation-carbonization process, prepared an average density of 2.9g / cm 3 Gradient metal type C / C slider.

[0048] Specific steps are as follows:

[0049] (1) The carbon fiber prefabricated body consists of two parts, the adhesive layer and the friction layer, which are connected into one body by needle punching. The bonding layer is composed of 0° latitude-free carbon cloth, carbon fiber mesh, copper mesh, 90° latitude-free carbon cloth, carbon fiber mesh, short copper wire, and latitude-free carbon cloth. The quality of the copper mesh and the quality of the short copper wire are respectively Accounting for 68% and 22% of the total mass of the bonding layer; the fr...

Embodiment 3

[0053] Using a felt body with a mass content of 56% copper in the bonding layer and a mass content of 50% copper in the friction layer as a prefabricated body, a composite material with a residual porosity of 16% was prepared by a chemical vapor deposition process. process, prepared an average density of 2.2g / cm 3 Gradient metal type C / C slider.

[0054] Specific steps are as follows:

[0055] (1) The carbon fiber prefabricated body consists of two parts, the adhesive layer and the friction layer, which are connected into one body by needle punching. The bonding layer is composed of 0° latitude-free carbon cloth, carbon fiber mesh, copper mesh, 90° latitude-free carbon cloth, carbon fiber mesh, copper powder, and latitude-free carbon cloth. The knot layer lays 55% and 15% of the total mass; the friction layer consists of 0° latitude-free carbon cloth, carbon fiber mesh tire, copper mesh, 90° latitude-free carbon cloth, carbon fiber mesh tire, copper mesh, and 0° latitude-fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com