Pantograph head structure capable of reducing offline rate of pantograph-contact line of electric locomotive

A technology for electric locomotives and pantographs, used in electric vehicles, current collectors, vehicle components, etc., can solve problems such as poor followability, increased electromagnetic interference noise, large motion mass and inertia, and achieve increased service life and reduced Electromagnetic noise and damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

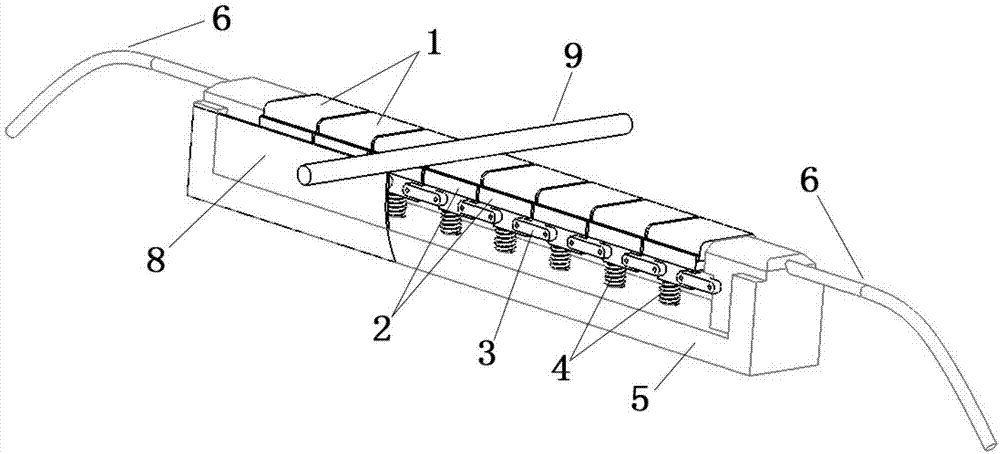

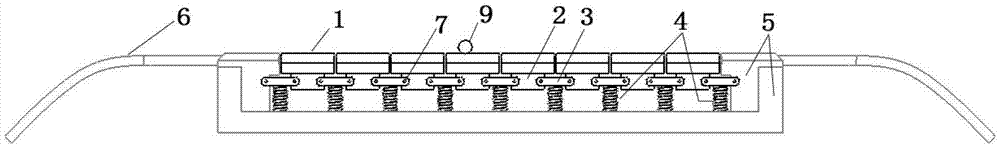

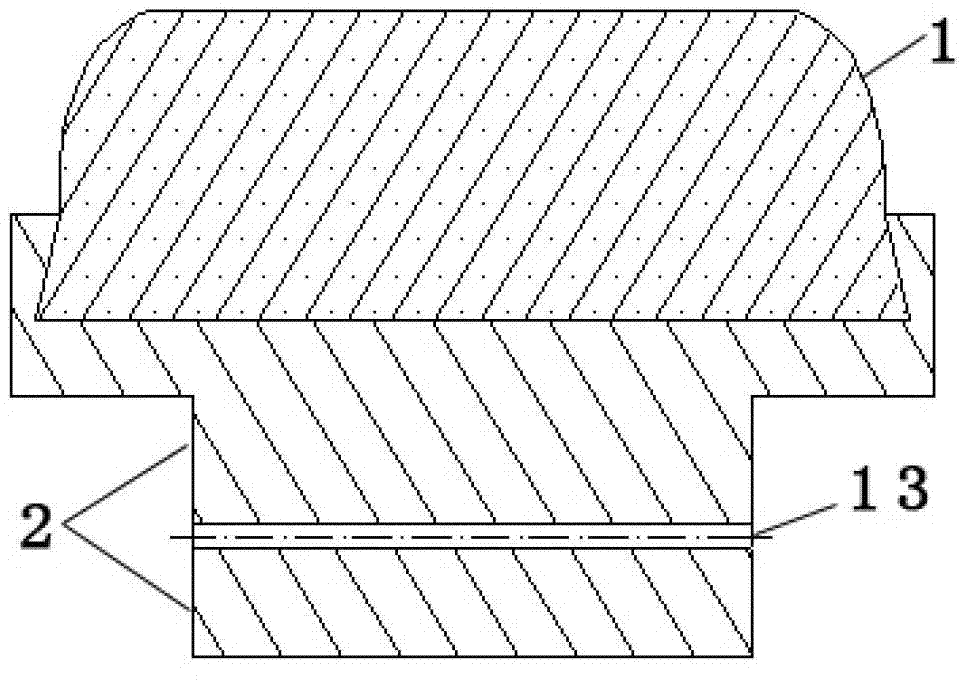

[0022] combine Figure 1 to Figure 6 , the structure of the pantograph bow head in this embodiment, the bow head slide plate in sliding contact with the contact wire 9 is composed of eight slide plates 1, each slide plate is made of carbon or powder metallurgy materials, such as Figure 4 As shown, the lateral width L of the slide plate is 60 mm, the front and rear edges 10 of the upper surface of the slide plate are arc-shaped (the use of right-angled edges is easy to cause scratches), and the bottom is dovetail-shaped 11 . Skateboard support block 2 is made of lightweight, corrosion-resistant and conductive aluminum, such as Figure 5 Shown, its top has the dovetail groove 12 that cooperates with the dovetail shape 11 of slide block bottom, and the bottom size shrinks inwardly, offers transparent shaft hole 13 in the bottom front and back wall both sides. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com