Device and method for accurately positioning spherical hinge

A precise positioning and ball hinge technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of poor accuracy, repeated adjustment, and low work efficiency, and achieve the effect of high work efficiency, high positioning accuracy and high positioning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

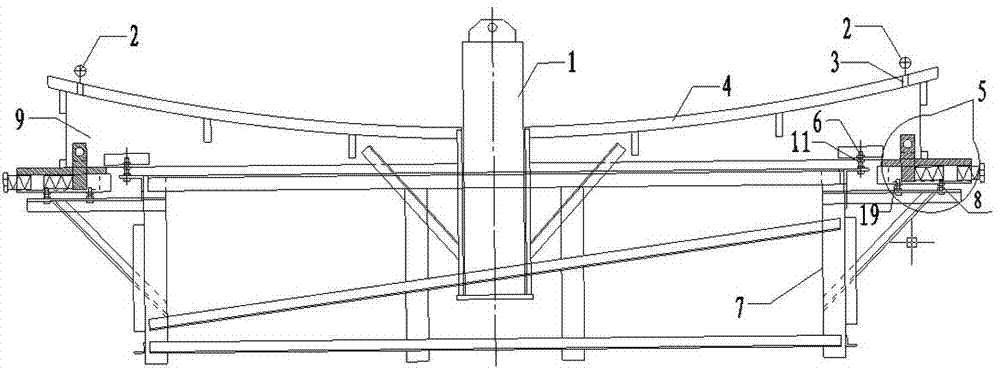

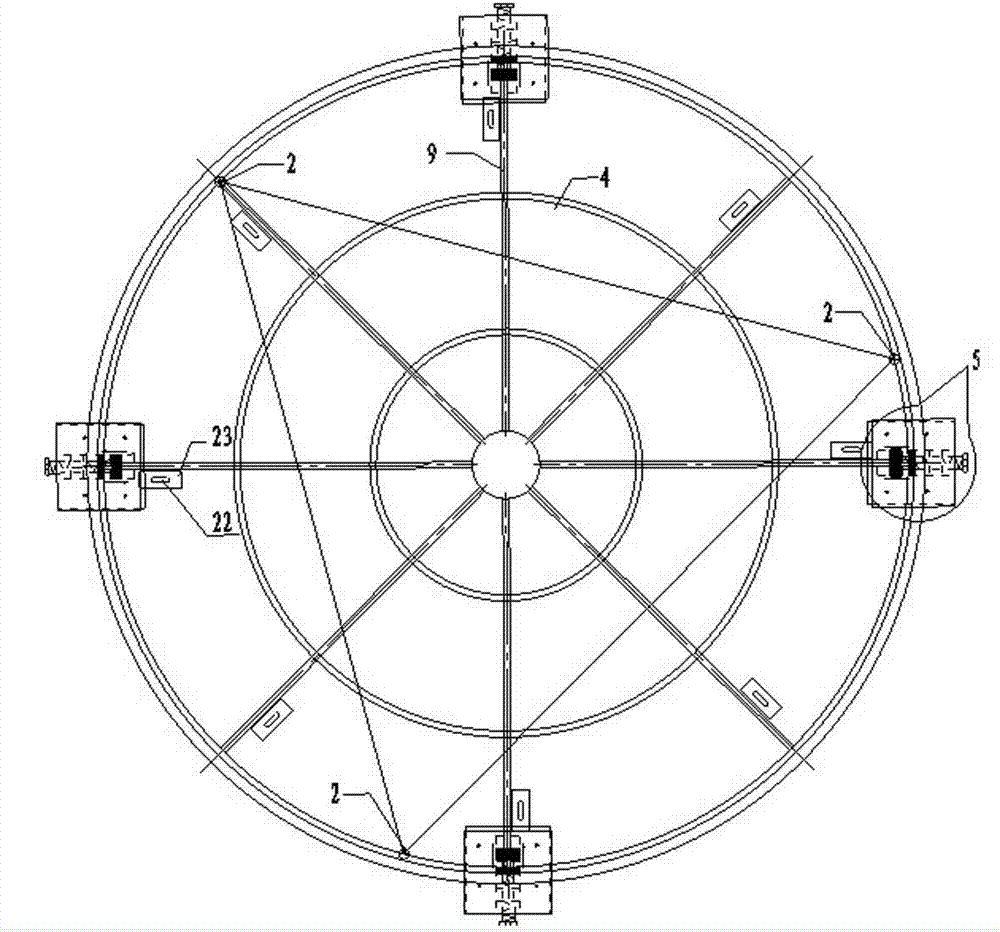

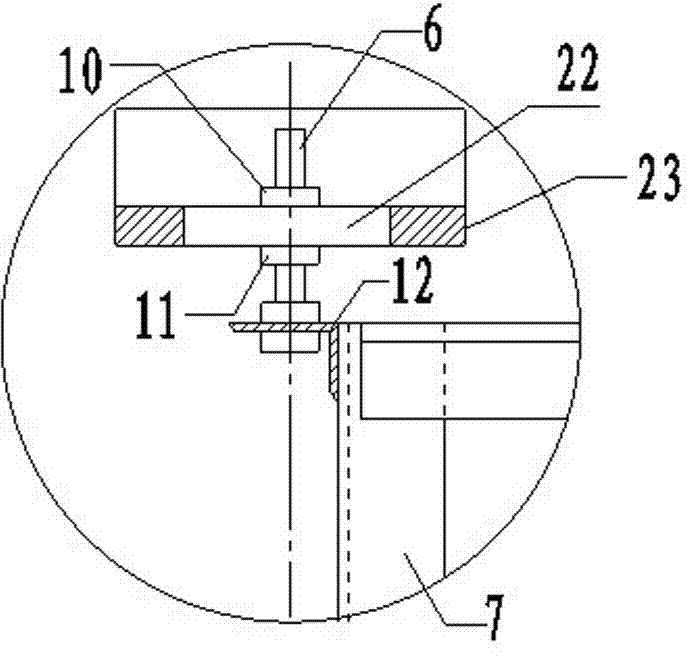

[0032] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0033] 1. During the processing of the lower ball joint, three prism connection kit installation holes are precisely processed on the edge of the ball joint, and the prism connection kit is installed inside. The three prism connection kits are arranged in an equilateral triangle on the circumference of the same radius. Make sure the prism is on the plumb line after installation.

[0034] 2. Roughly adjust the positioning framework of the lower ball joint in place according to the measurement points, control the installation accuracy of the elevation and plane position of the positioning framework within ±10mm, and weld the positioning framework and the bridge bearing embedded parts under the positioning framework firmly.

[0035] 3. Hoist the lower ball joint to the positioning frame, install the locking device between the lower ball joint and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com