Double motor driven backlash eliminating device and backlash eliminating method

A dual-motor drive, anti-backlash technology, applied in the direction of speed adjustment of multiple motors, can solve the problems of control requirements, insurmountable transient errors, and unattainable control accuracy, achieving high transmission accuracy, stable and accurate control loops , control accurate and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

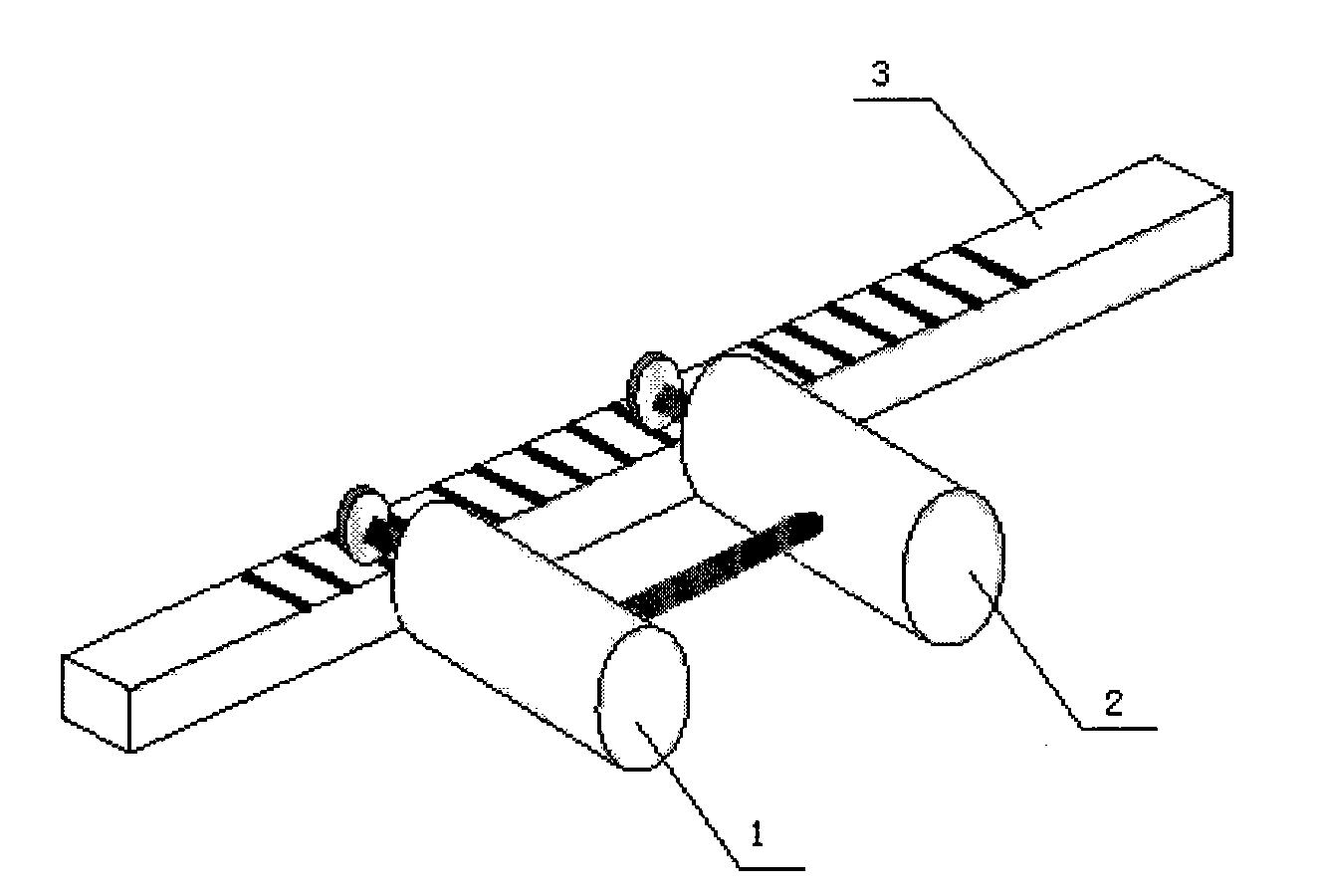

[0023] figure 1 The structure schematic diagram of the present invention is given, and the double-motor-driven anti-backlash device of the present invention includes a first motor 1, a second motor 2 and a rack 3, and the rack 3 shown is fixed on a guide table, which can be The horizontal guide rail platform can also be a platform in other directions. The rack 3 is in a static state when the workbench is moving or stationary, and the first motor 1 and the second motor 2 are fixed on the workbench. The two matching gears are respectively connected with the first motor 1 and the second motor 2 through a transmission mechanism.

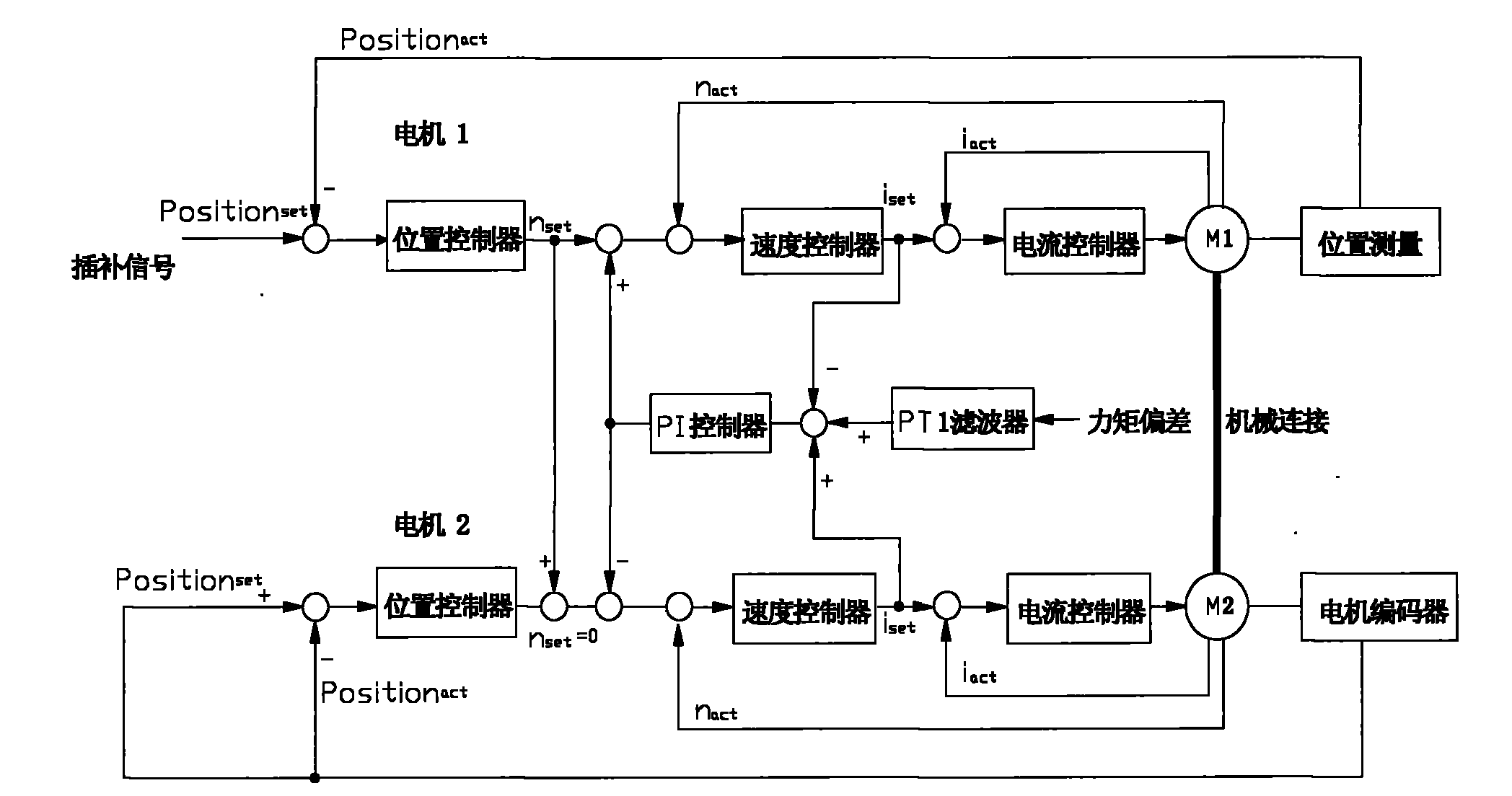

[0024] figure 2 This is the schematic diagram of the circuit control system. The control systems of the first motor 1 and the second motor 2 include motor encoders, position controllers, speed controllers, current controllers, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com