Planetary gear speed reducer

A technology of planetary gear reduction and reducer, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., and can solve the problems of important parts damage, planet carrier strength enhancement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

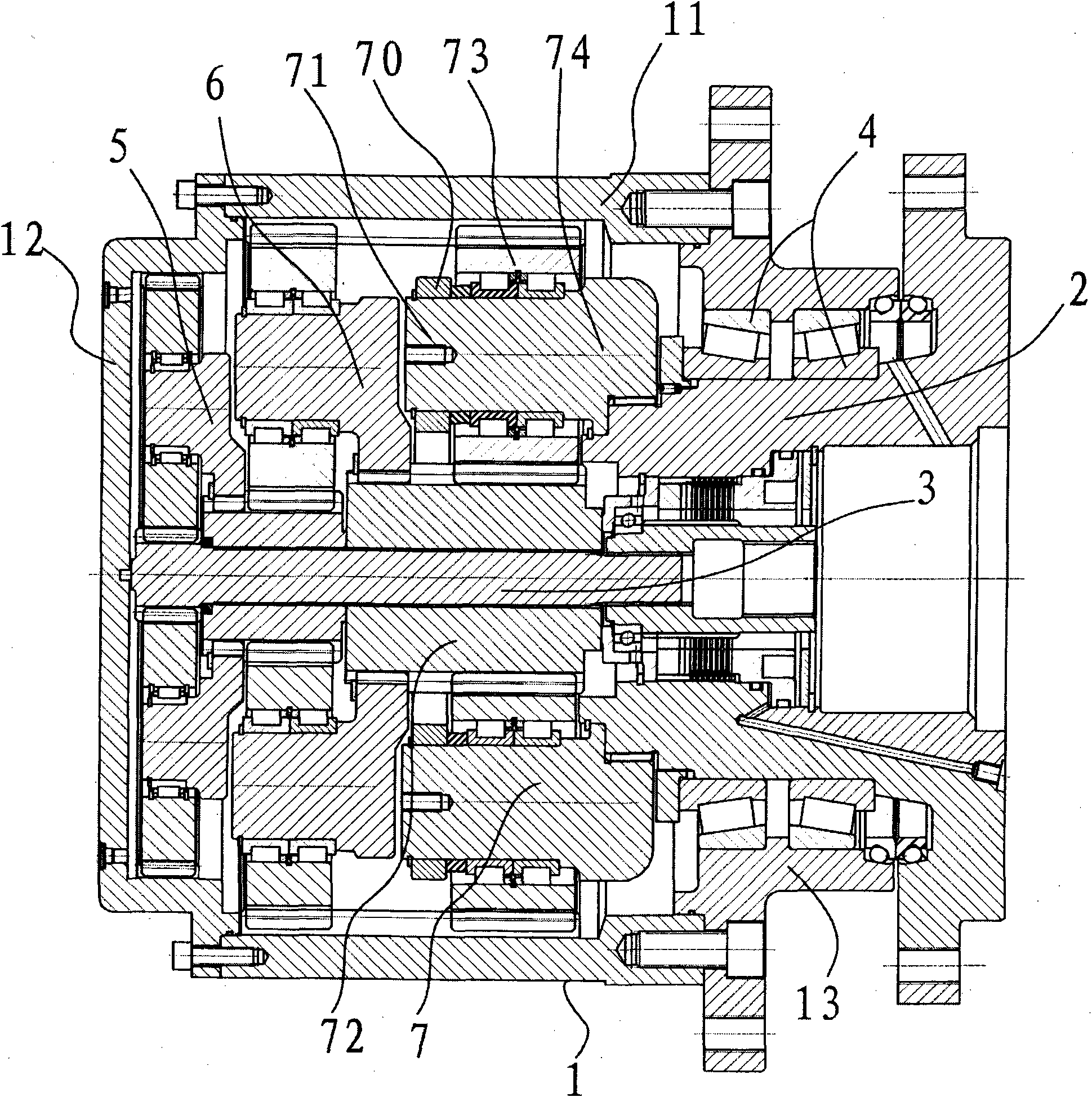

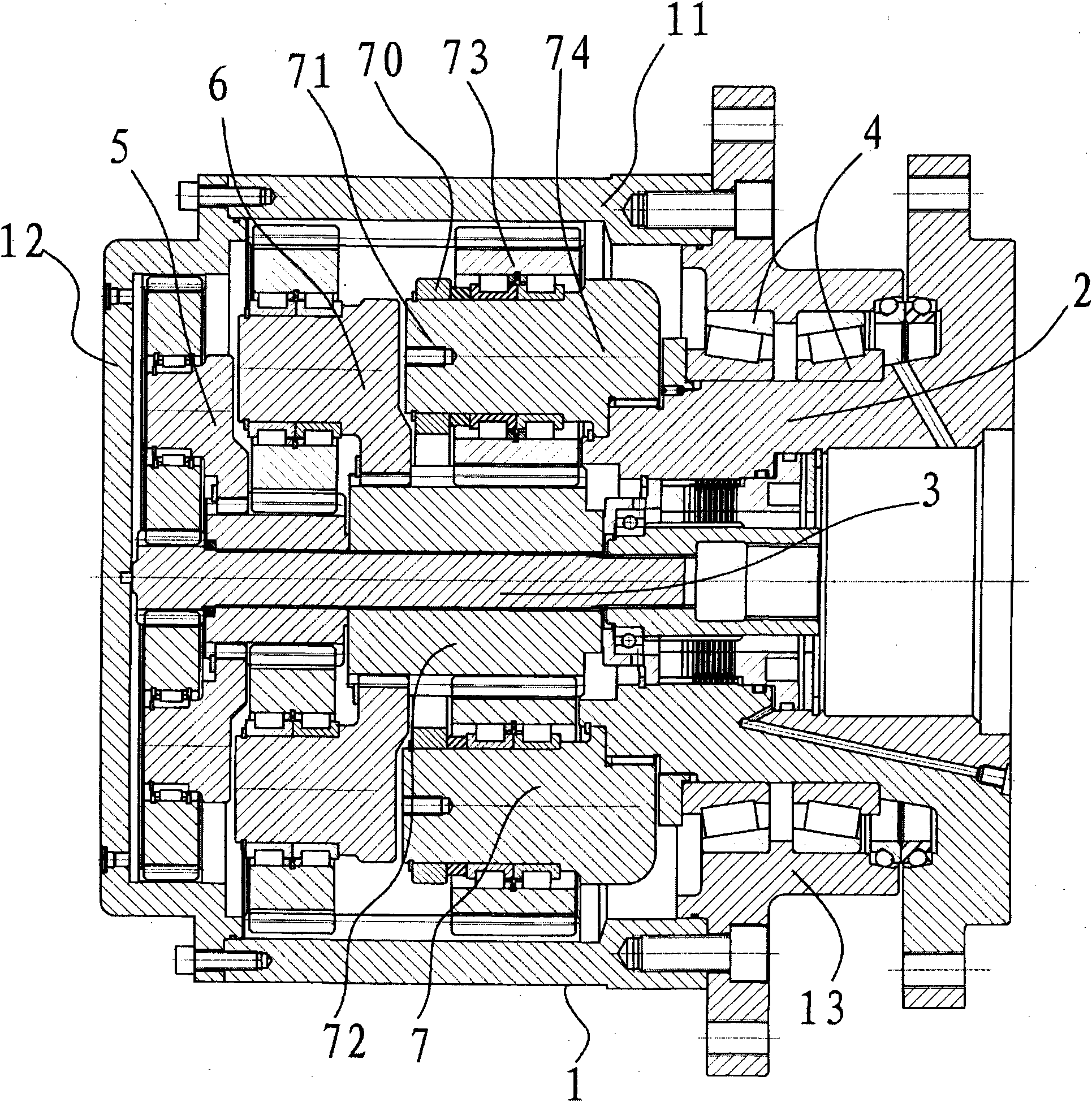

[0013] The present invention will be further explained below in conjunction with the drawings.

[0014] See figure 1 , A planetary gear reducer, including a housing 1 as a torque output end, a bracket flange 2 assembled with the housing through a bearing, a spline sleeve 3 as a high-speed input shaft of the reducer, and a housing The input torque is transmitted to the first-stage planetary gear train 5, the second-stage planetary gear train 6 and the third-stage planetary gear train 7 of the housing through gears. The three-stage planetary carrier 74 of the third-stage planetary gear train is provided with three One-stage planet carrier side plate 70 and five cantilever beam cylinders 71 integrally cast with the planet carrier body, and the bearings at the junction of the shell and the bracket flange are two single-row tapered roller bearings 4. The spline sleeve is connected with an external power source, and passes through the three-stage planetary gear train, the two-stage pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com