Detachable assembled bay window mold

An assembled, bay window technology, applied to molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of inability to reduce the friction area of the bay window, reduce the pulling speed of the hoisting device, and the difficulty of demoulding, so as to reduce the hoisting time. , reduce the contact area and avoid the effect of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

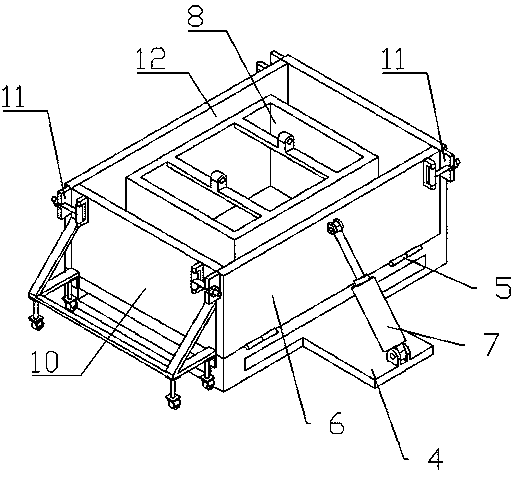

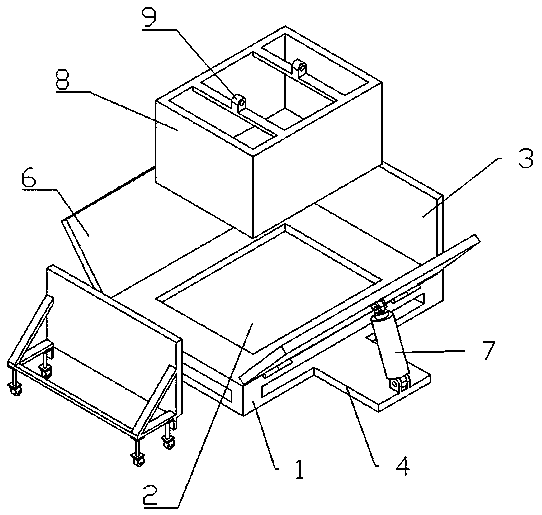

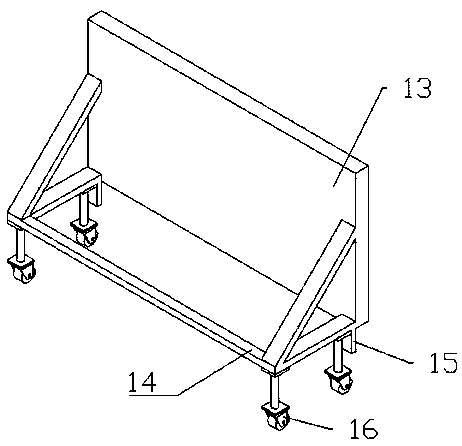

[0014] like Figure 1-3 As shown, a detachable assembled bay window mold includes a mold base 1, a slot 2, a fixed plate 3, a hydraulic cylinder seat 4, a hinge 5, a side plate 6, a hydraulic cylinder 7, a window mold 8, and a lifting seat 9 , moving plate 10, plate buckle 11, pouring cavity 12, the middle of the mold base 1 has a rectangular slot 2, the right end of the mold base 1 is provided with a vertical fixed plate 3, the mold base 1 is fixed with The hydraulic cylinder base 4, the two side plates 6 are hinged front and rear with the mold base 1 through hinges 5, the two ends of the hydraulic cylinder 7 are respectively connected to the hydraulic cylinder base 4 and the side plates 6, and the window mold 8 is a rectangular body, The window mold 8 is slidingly connected with the draw-in groove 2, the top of the window mold 8 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com