Ice machine inflow water heating pipe, assembly structure of ice machine inflow water heating pipe and refrigerator door body and refrigerator

A technology for assembling structure and refrigerator door body, which is applied in the directions of ice making, ice making, household refrigerators, etc., can solve the problem of inconvenient replacement of foaming water pipes, achieve good anti-icing effect, reduce production process steps, and improve The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

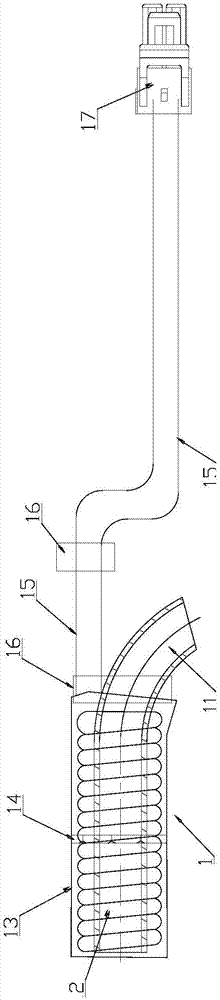

[0036] Such as figure 1 As shown, the water inlet heating pipe of the ice maker of this embodiment includes a metal pipe 11, a heating wire 12 wound on the outer wall of the metal pipe 11, and an insulating heat-preserving sheath 13, and the insulating heat-preserving sheath 13 is sealed and sleeved in the Outside the metal tube 11, the heating wire 12 is sealed between the metal tube 11 and the edge insulation sheath 13 and is electrically connected to the main control board of the ice maker 6; one end of the water inlet tube 2 The metal pipe 11 is sealed and inserted into the metal pipe 11, and one end of the metal pipe 11 away from the water inlet pipe 2 is communicated with the ice making chamber of the ice maker 6. The heating wire 12 of this embodiment can cover the outer side wall of the metal pipe 11, or it can only be provided on a section of the metal pipe 11. The metal pipe 11 only needs to perform the heating on the end of the water inlet pipe 2 close to the ice maki...

Embodiment 2

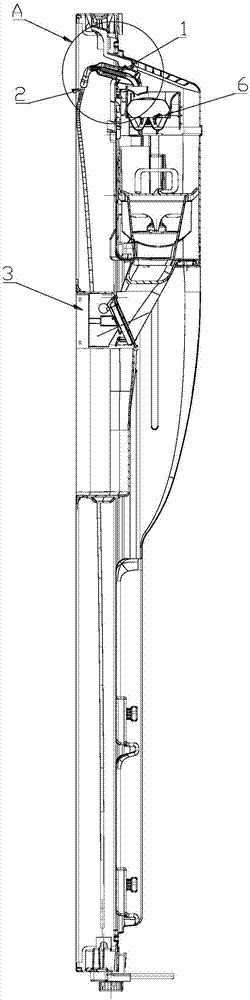

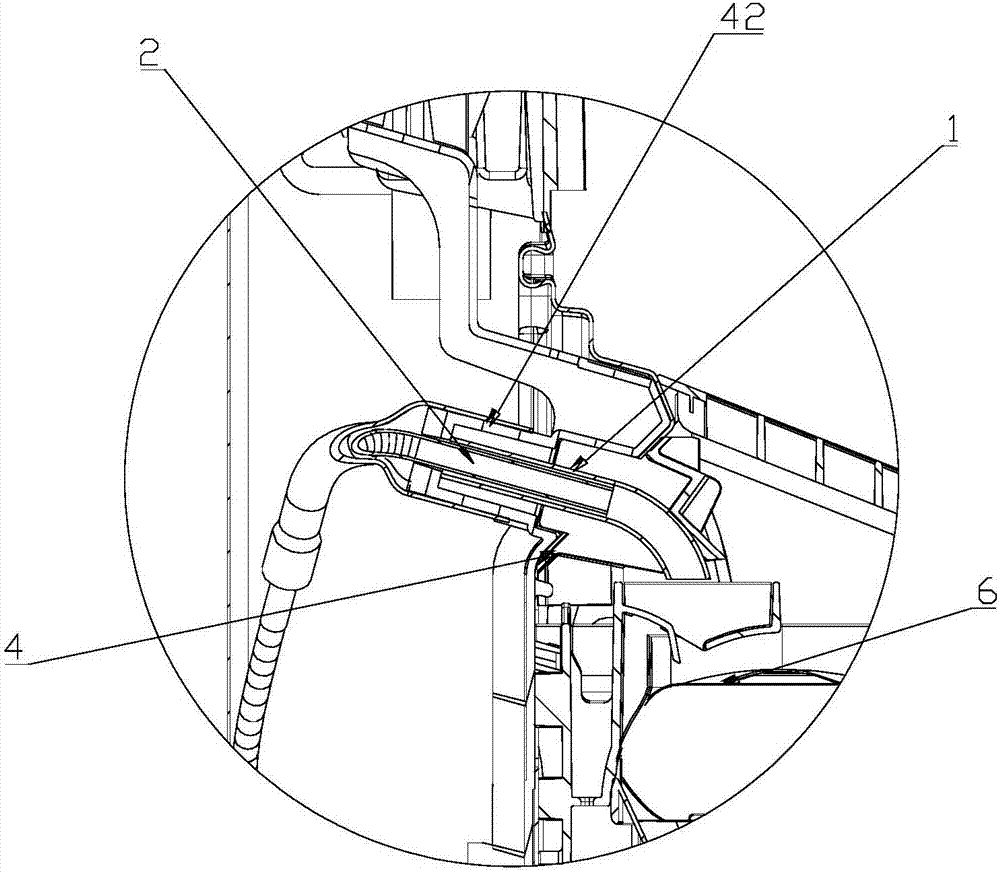

[0040] Such as Figure 2-Figure 6 As shown, the assembly structure of the refrigerator door 3 of this embodiment and the heating pipe 1 described in Example 1, the inner liner of the refrigerator door 3 is installed with a pre-embedded base 4, The buried base 4 is provided with an installation channel, one end of the heating tube 1 is inserted into the installation channel and is in interference fit with the inner side wall of the installation channel, and the other end of the heating tube 1 is connected to the ice making channel. The chambers are connected; the water inlet pipe 2 is inserted into one end of the heating pipe 1.

[0041] Such as Figure 4 As shown, the ice maker 6 of this embodiment includes an ice maker body 61, an ice bank assembly 62, and a motor 63. The ice maker body 61 is mounted on the embedded base 4, and the ice bank assembly 62 is mounted on At the lower end of the ice maker body 61, the motor 63 is installed in the ice maker body 61.

[0042] Such as I...

Embodiment 3

[0048] Such as Figure 7 As shown, a refrigerator in this embodiment includes a refrigerator door 3, an ice maker 6, a water inlet pipe 2 and the heating pipe 1 described in Example 1. The ice maker 6 is installed on the refrigerator door 3 On the inner side of the refrigerator, the water inlet pipe 2 and the heating pipe 1 are assembled on the inner side of the refrigerator door 3 using the assembly structure described in Embodiment 2.

[0049] In the refrigerator of this embodiment, the water inlet pipe 2 is installed between the foamed layer of the refrigerator door 3 and the steel plate, the foamed layer of the refrigerator door 3 is provided with a through hole, and the mounting tube 42 on the embedded base 4 is inserted In the through hole, the water inlet pipe 2 is inserted into the installation channel from the end of the installation cylinder 42 between the foamed layer and the steel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com