Residential building prefabricated bay-window construction structure and method

A technology of prefabrication assembly and construction method, which is applied in the direction of building construction, formwork/formwork/working frame, and on-site preparation of building components. Problems such as molds can be solved to achieve the effects of improving molding quality, energy saving and environmental protection, and reducing secondary construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

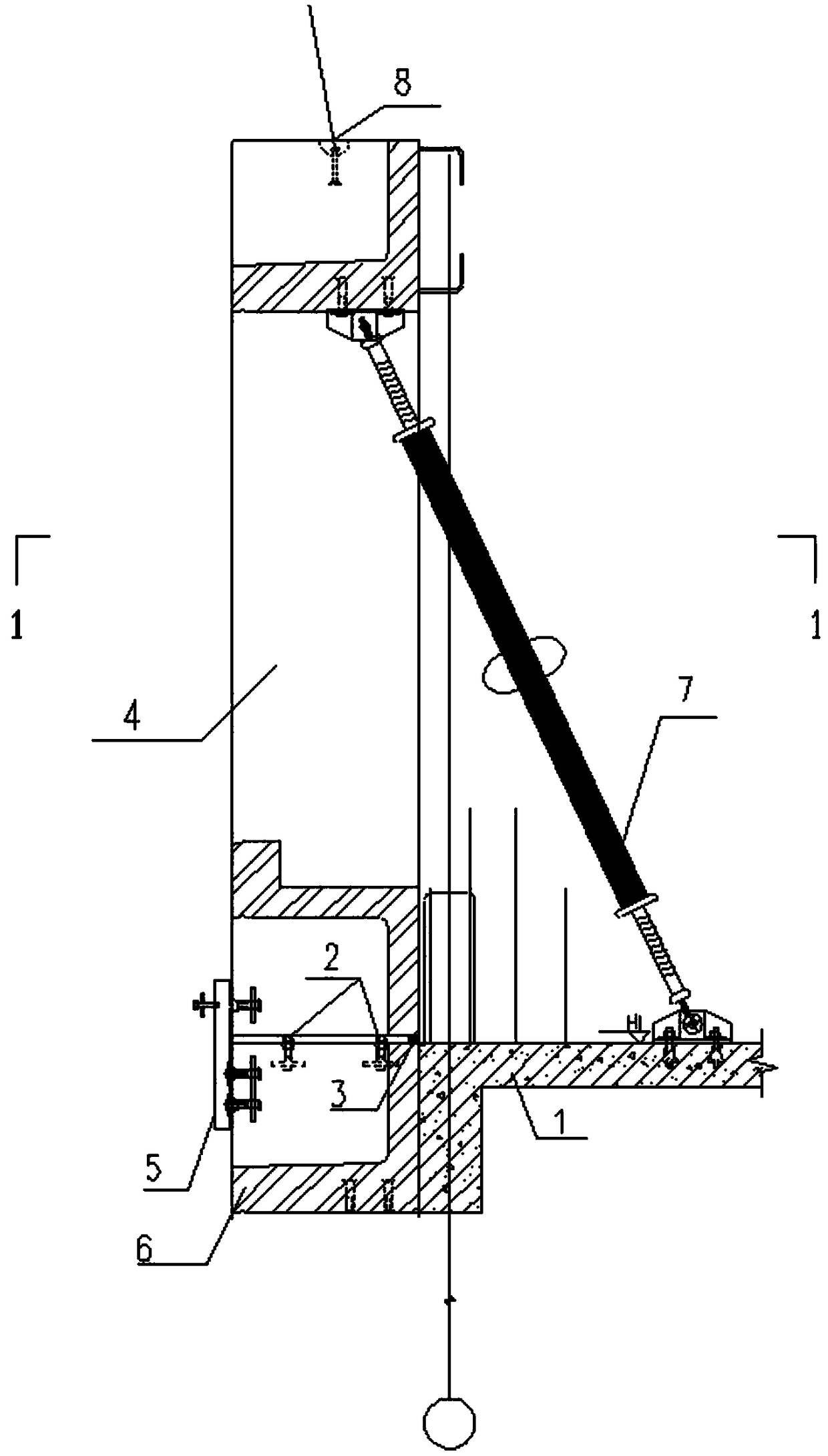

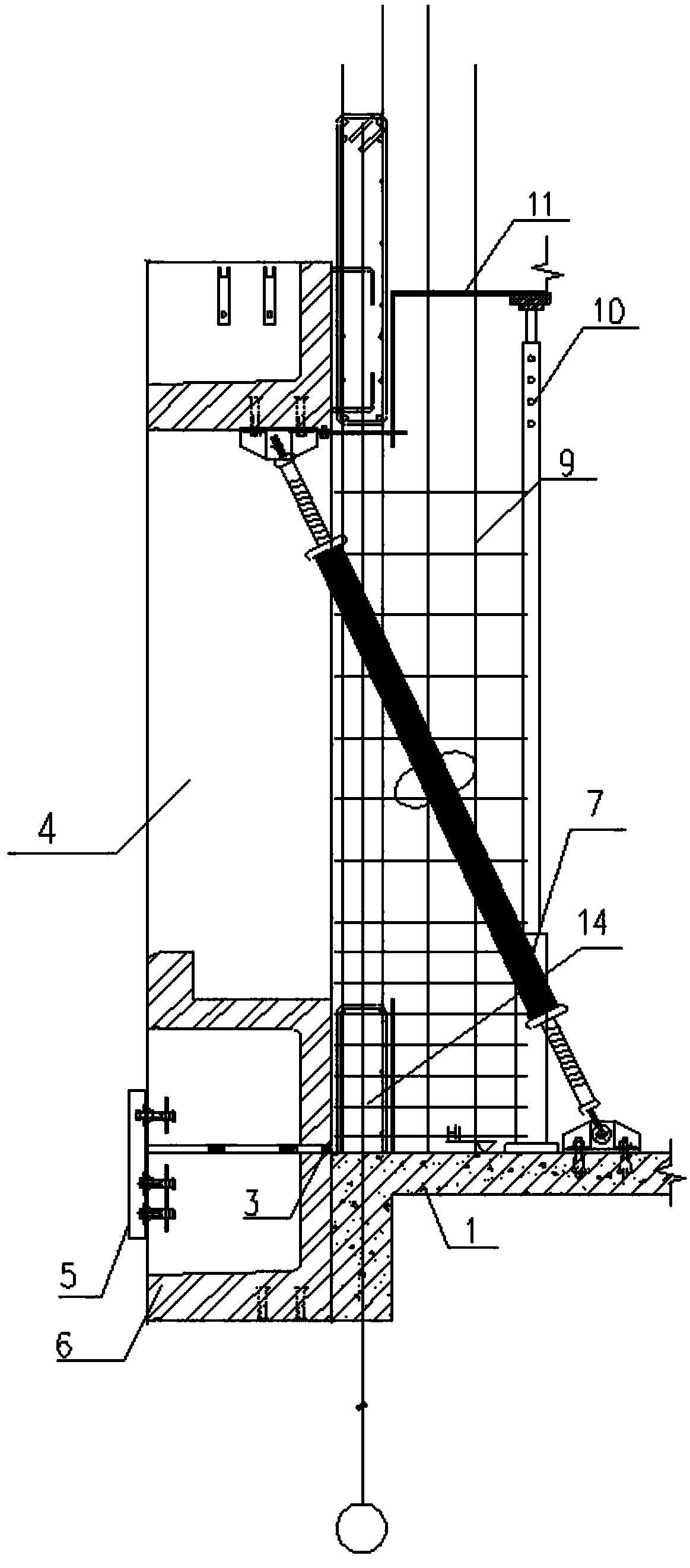

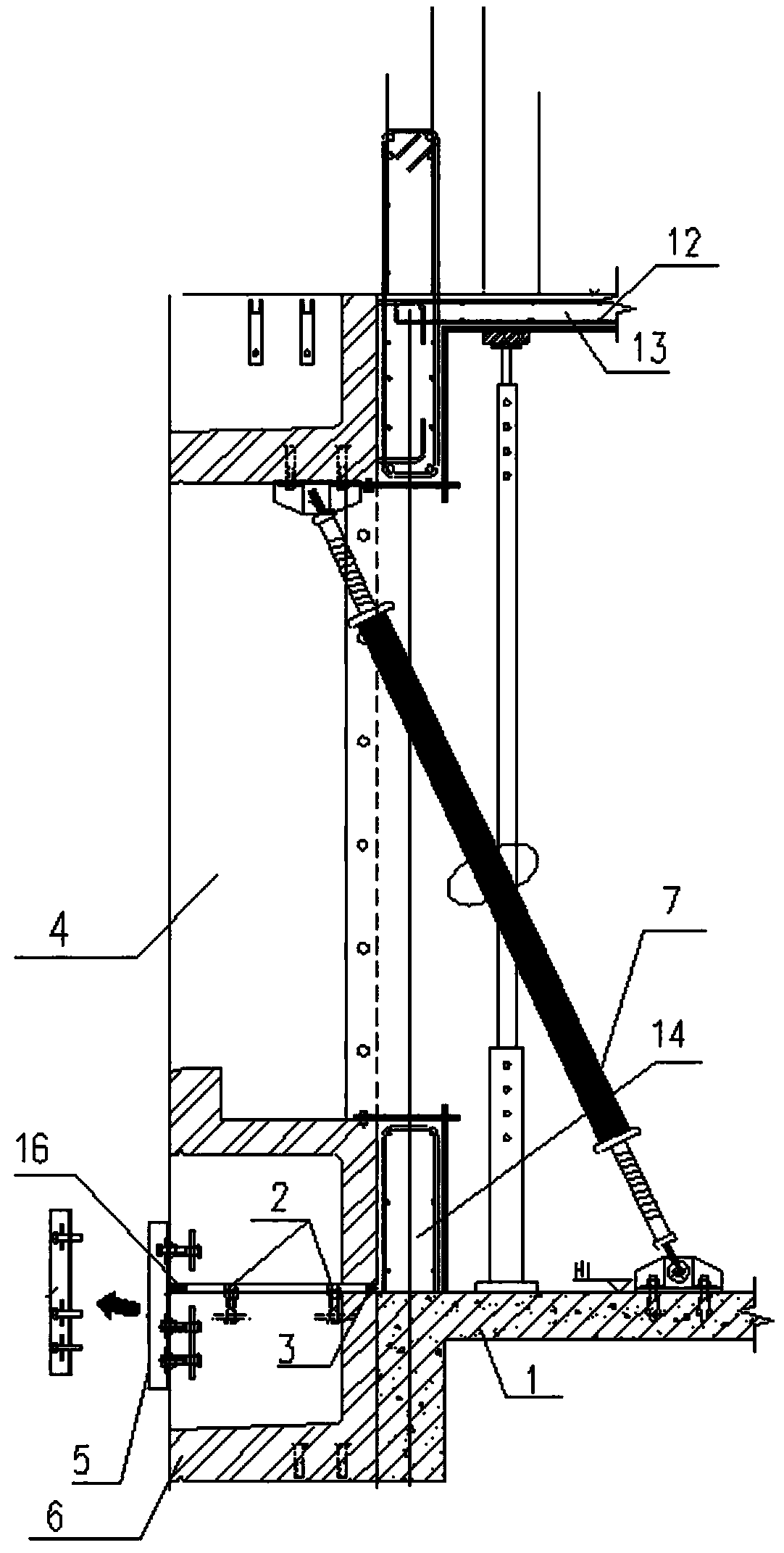

[0018] refer to Figure 1 to Figure 4 , the present embodiment provides a prefabricated bay window construction structure of a residential building, including a lower PC6 poured on the outer side of the lower beam slab 1, the upper end of the lower PC6 is vertically screwed with a bolt 2, and the top elevation of the bolt 2 is Hi+ 0.020, the upper part of the lower PC6 is docked with the upper member 4, and the inner side of the joint between the lower PC6 and the upper member 4 is pressed with a PE rod 3, and the outer side of the lower PC6 and the upper member 4 are fixedly connected by the connector 5, and the upper member 4 A diagonal brace 7 is also installed between the lower beam plate 1, and the lower end of the diagonal brace 7 is fixed on the lower beam plate 1 in the room, and the upper end of the diagonal brace 7 is fixed on the upper part of the upper member 4.

[0019] Its specific construction method is as follows:

[0020] First, the concrete pouring of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com