Prefabricated bay window and installation method

An installation method and bay window technology, which is applied in the field of bay windows, can solve the problems that the walls must be cast-in-place, and achieve the effects of simplifying the construction and installation process, improving waterproof performance, and reducing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

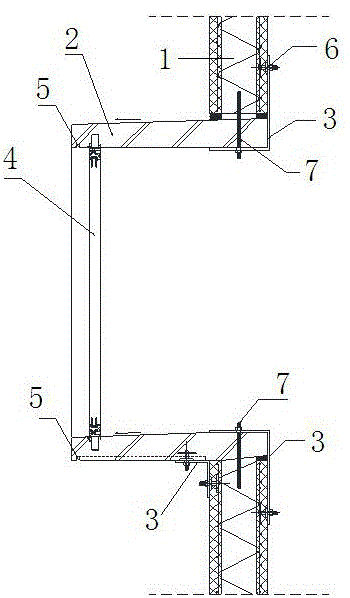

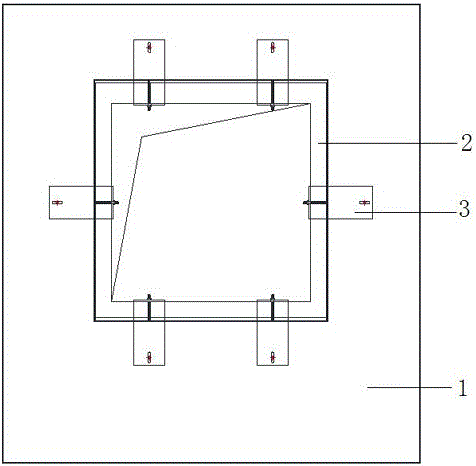

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0021] A prefabricated bay window, comprising a window frame and a concrete prefabricated "mouth"-shaped window, the window frame is arranged at the outer end inside the window; the upper surface of the upper and lower eaves of the window is provided with A slope of 2° extending from the inner end of the form to the outer end.

[0022] The slope not only facilitates rainwater to flow down the slope, but also facilitates demoulding of the prefabricated form, and facilitates filling of caulking mortar at the connection between the form and the wall.

[0023] The outer ends of the lower surfaces of the upper eaves and the lower eaves of the form are provided with grooved drip grooves, and the drip grooves are arranged on the outside of the window frame. Recessed gutters prevent rainwater from flowing down the entire lower surface of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com