Integrally-prefabricated U-shaped bay window component and fabricated bay window joint structure and construction method thereof

An overall prefabricated and assembled technology, applied to building components, building structures, balconies, etc., can solve the problems of poor construction, poor fixation, increased difficulty and cost of production, etc., to ensure structural safety and improve overall safety. Strength, the effect of strengthening the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

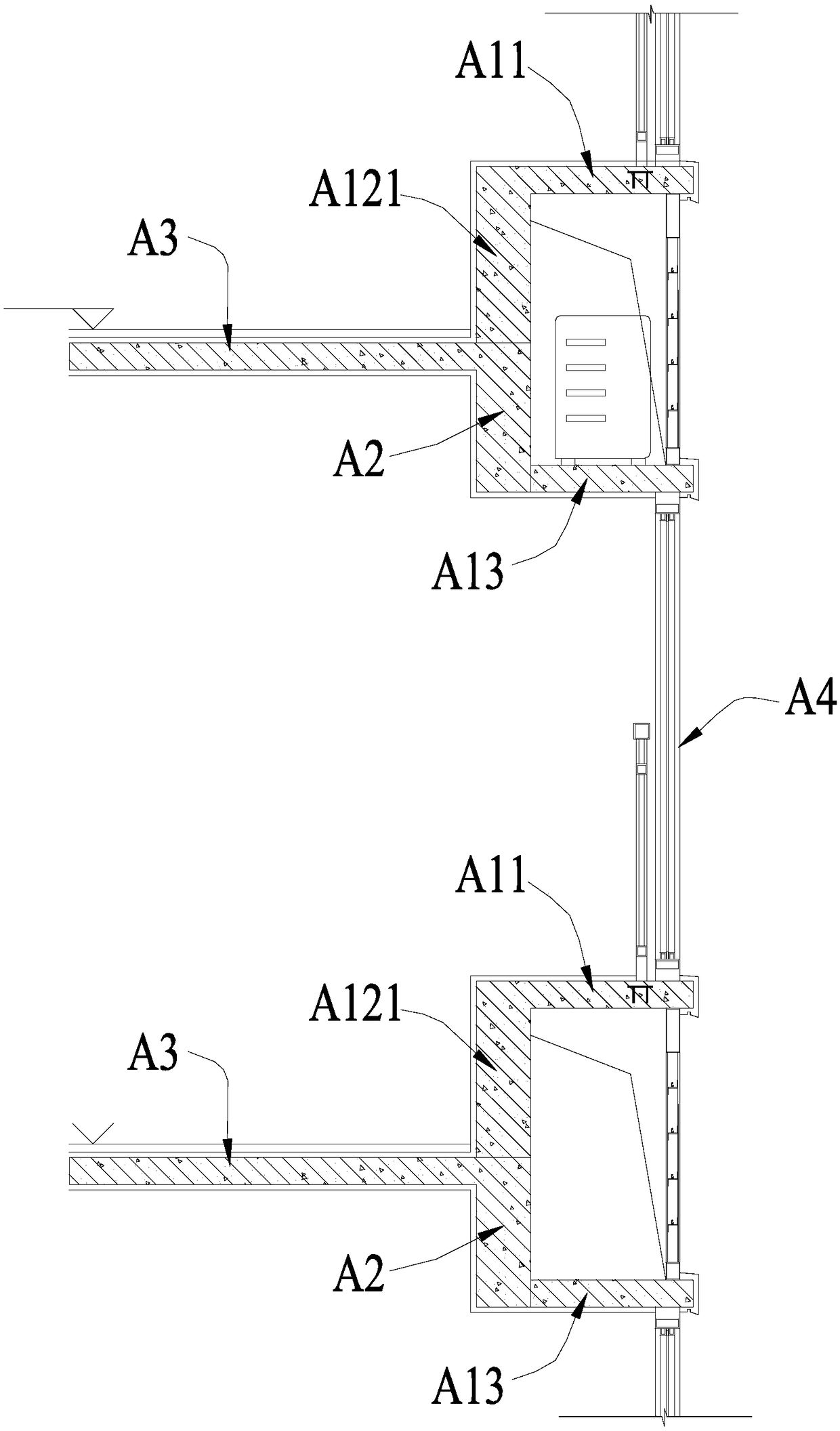

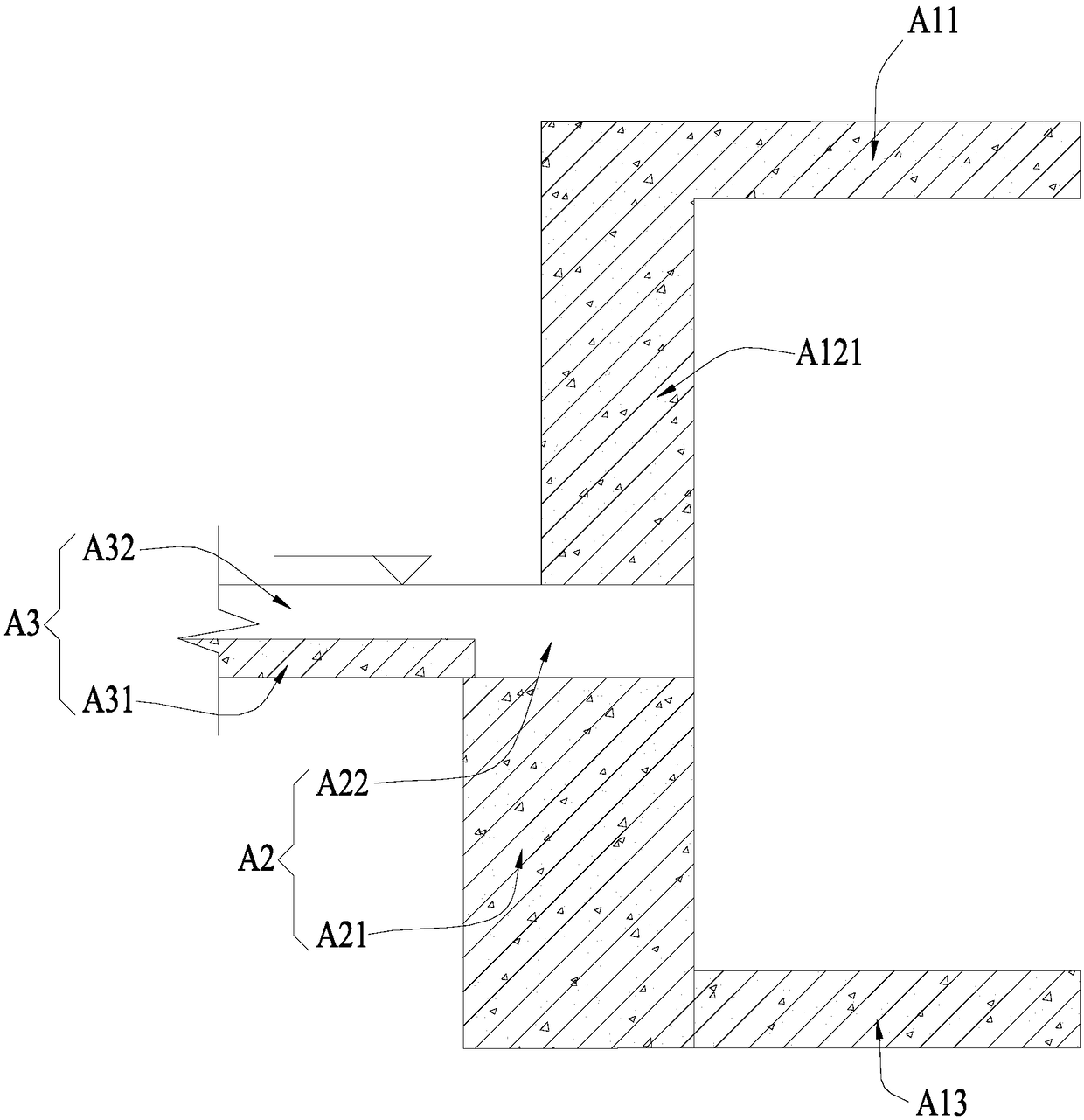

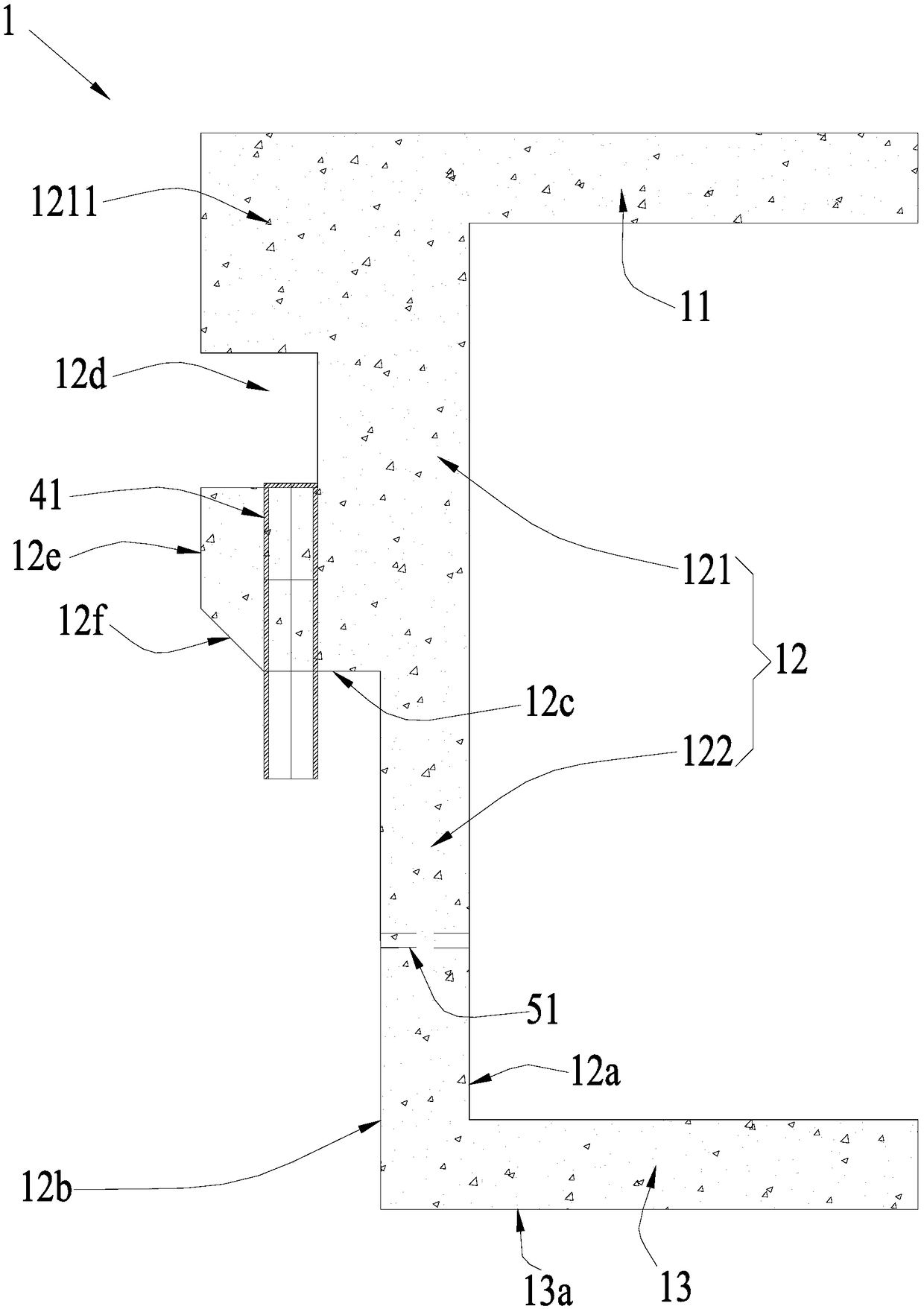

[0059] The lower part 122 of the second plate 12 of the U-shaped integral prefabricated bay window component 1 has a plurality of sleeves 51 embedded therein, and each sleeve 51 is arranged at intervals along the width direction of the U-shaped integral prefabricated bay window component 1, and each sleeve The tubes 51 both pass through the outer side 12a and the inner side 12b of the lower part 122 of the second plate 12;

[0060] The structural beam prefabricated part 21 corresponds to each casing 51 of the U-shaped integral prefabricated bay window component 1 with a threaded sleeve 52 pre-embedded, and the port of each threaded sleeve 52 is exposed on the outer surface of the structural beam prefabricated part 21 , so that: after step 2 is completed, the port of each threaded sleeve 52 is communicated with the corresponding casing 51;

[0061] Step 3 further includes: setting a bolt 53 corresponding to each set of connected sleeves 51 and threaded sleeves 52 , and connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com