Horizontal steel bar planting structure and construction method

A rebar-planting and horizontal technology, applied in building construction, construction, and building materials processing, etc., can solve the problems of mismatched design service life of permanent concrete structures, poor durability of chemical rebars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

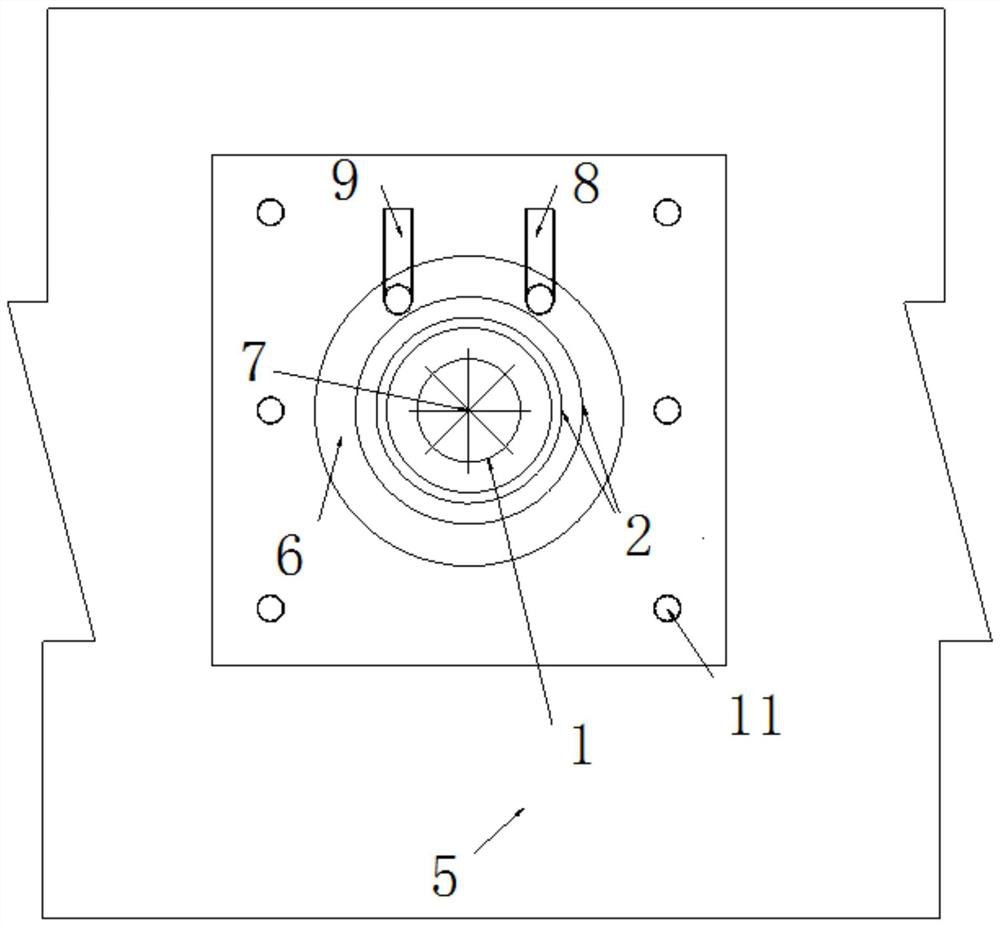

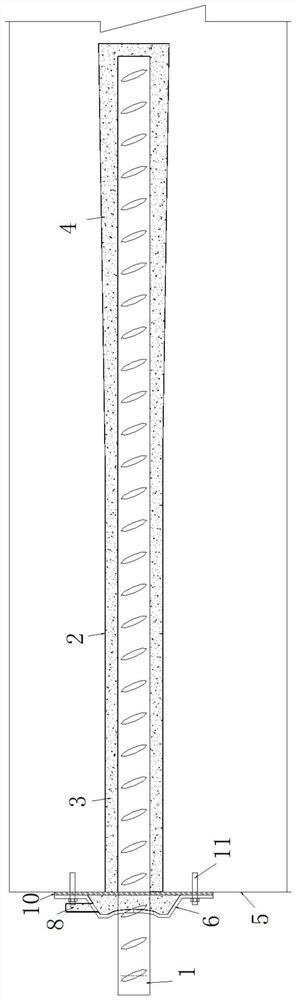

[0031] like figure 1 and figure 2 As shown, the horizontal bar planting structure includes implanted steel bars 1 and horizontal bar planting channels 2; the bar planting channel 2 is a blind hole, including an open end and a closed end.

[0032] Wherein, the part near the opening end of the planting reinforcement channel 2 is a horizontal straight section 3 with constant aperture, and the part near the closed part is a wedge-shaped reaming and widening section 4 with gradually larger aperture;

[0033] The opening end is set on the bar-planting base structure 5; the bar-planting base structure 5 is provided with a sealing cover 6 with a grouting port 8 and a grouting port 9;

[0034] The central position of the sealing cover 6 of the grouting port is provided with a planting reinforcement insertion hole 7;

[0035] The grouting port sealing cover 6 is provided with a grouting port 8 and a grouting port 9 on the top side;

[0036] The heights of the grouting port 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com