Fabricated building component hoisting comprehensive equipment and construction method thereof

A building component, prefabricated technology, applied in building construction, construction, building material processing and other directions, can solve the problems of low construction efficiency and difficult positioning, achieve accurate hoisting and installation positioning, improve work efficiency and safety The effect of high practicability, high availability and market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

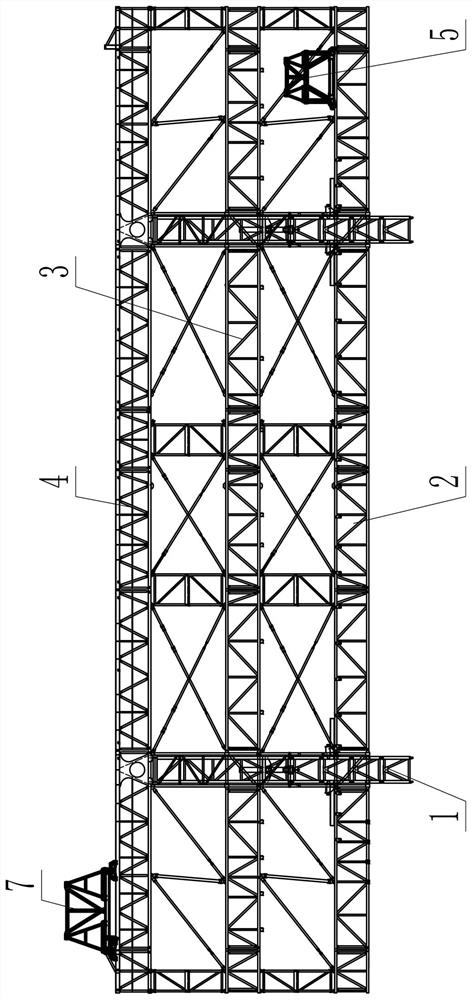

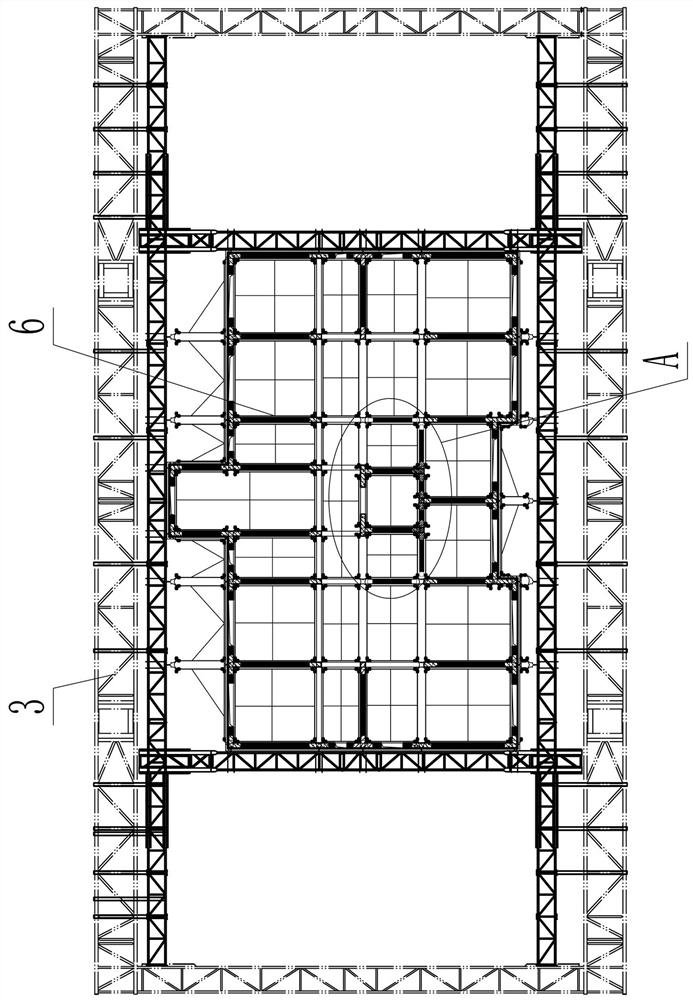

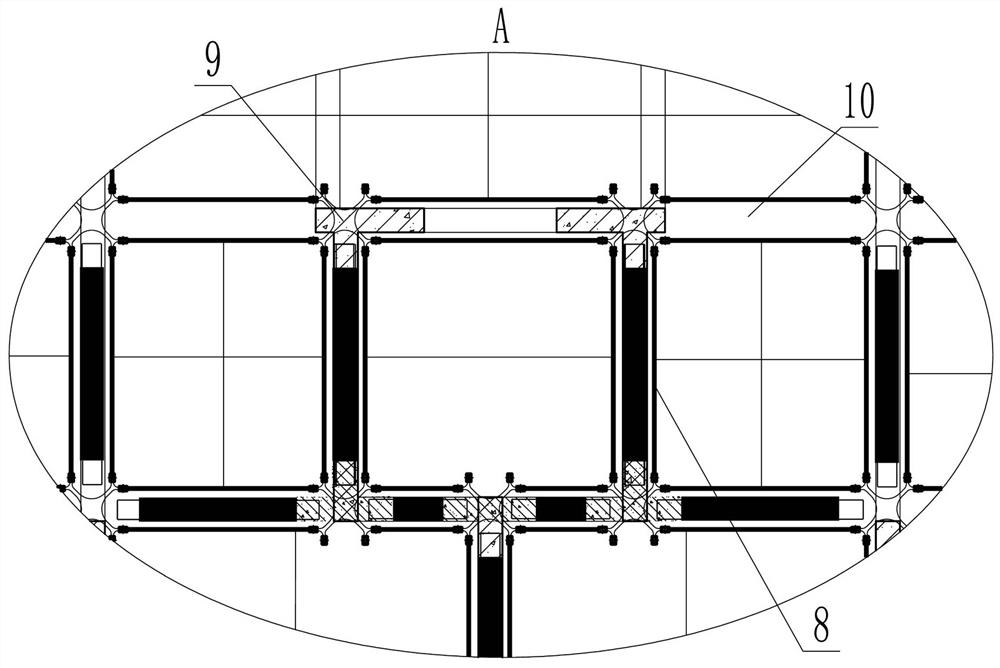

[0022] Depend on Figure 1 to Figure 7 Given, the present invention comprises special hoisting platform; Below the special hoisting platform, there is a support mast 1 arranged on the periphery of the building body, the mast support is a steel structure, and the support mast 1 is designed to be composed of standard sections of different sizes, through The assembly method of standard sections can meet the construction requirements of prefabricated houses with different storey heights. The center of each mast is equipped with a synchronous jacking system for jacking of special lifting platforms. The jacking system is equipped with load and cylinder stroke monitoring devices. Real-time monitoring of the load and stroke of the oil cylinder; the special lifting platform is a steel structure, including the first track layer 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com