Exchange technology of hot air furnace hot air short pipe

A technology of hot blast stove and short pipe is applied in the field of replacement technology of hot blast short pipe to achieve the effects of ensuring quality, reducing the difficulty of hoisting and shortening the construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

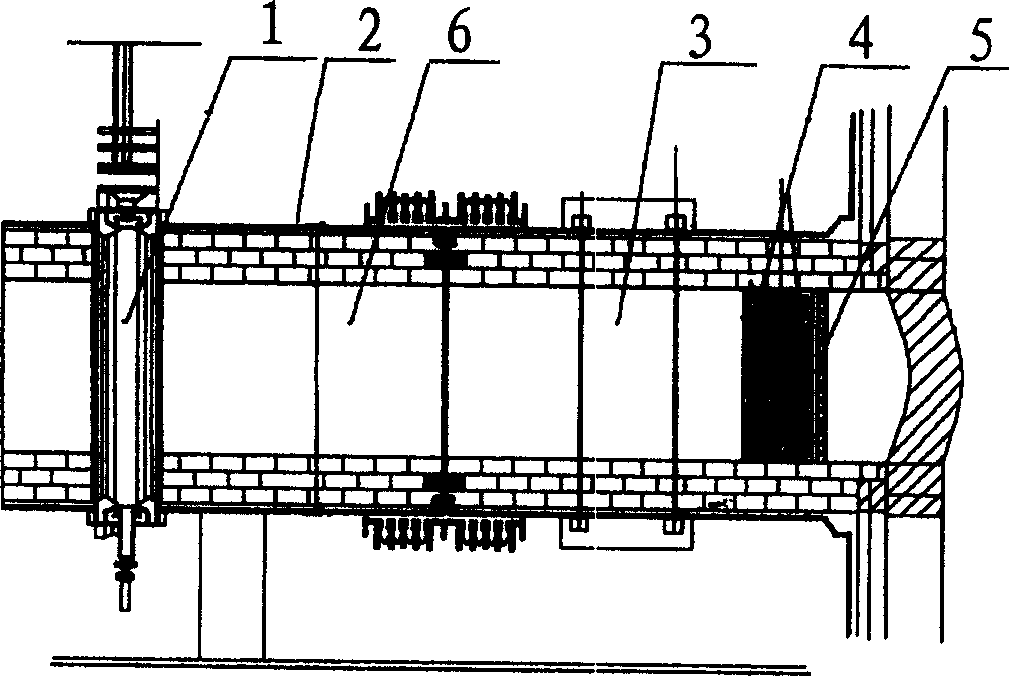

[0022] combine figure 1 , the hot blast short tube of the hot blast stove is replaced under the condition of continuous wind, it is mainly heat-insulated by the repaired hot blast stove, the hot blast valve 1 is closed, and the flue valve is opened small so that the hot blast stove is under negative pressure relative to the short hot blast tube 2. Build a fire-retaining wall 4 in the short pipe on the side of the furnace, remove the damaged short hot air pipe, install a new short hot air pipe 2 and a detachable short pipe 3, remove the detachable short pipe 3, build the inner lining of the short hot air pipe 2, remove the baffle The firewall 4 is composed of processes such as installing the detachable short pipe 3. The heat preservation treatment of the repaired hot blast stove should be done two hours before construction, on the one hand to ensure the safety of the construction, on the other hand to ensure that the repaired hot blast stove can be put into production as soon a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com