Self-balance type hoisting tool for steel containment module of nuclear power plant

A self-balancing, containment technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of difficult to set up lifting points, occupy the lifting capacity of the crane, and the weight of the lifting beam is large, so as to reduce the time required for hoisting. , The effect of reducing the overall weight and size, and reducing the difficulty of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A nuclear power plant steel containment module self-balancing hanger according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

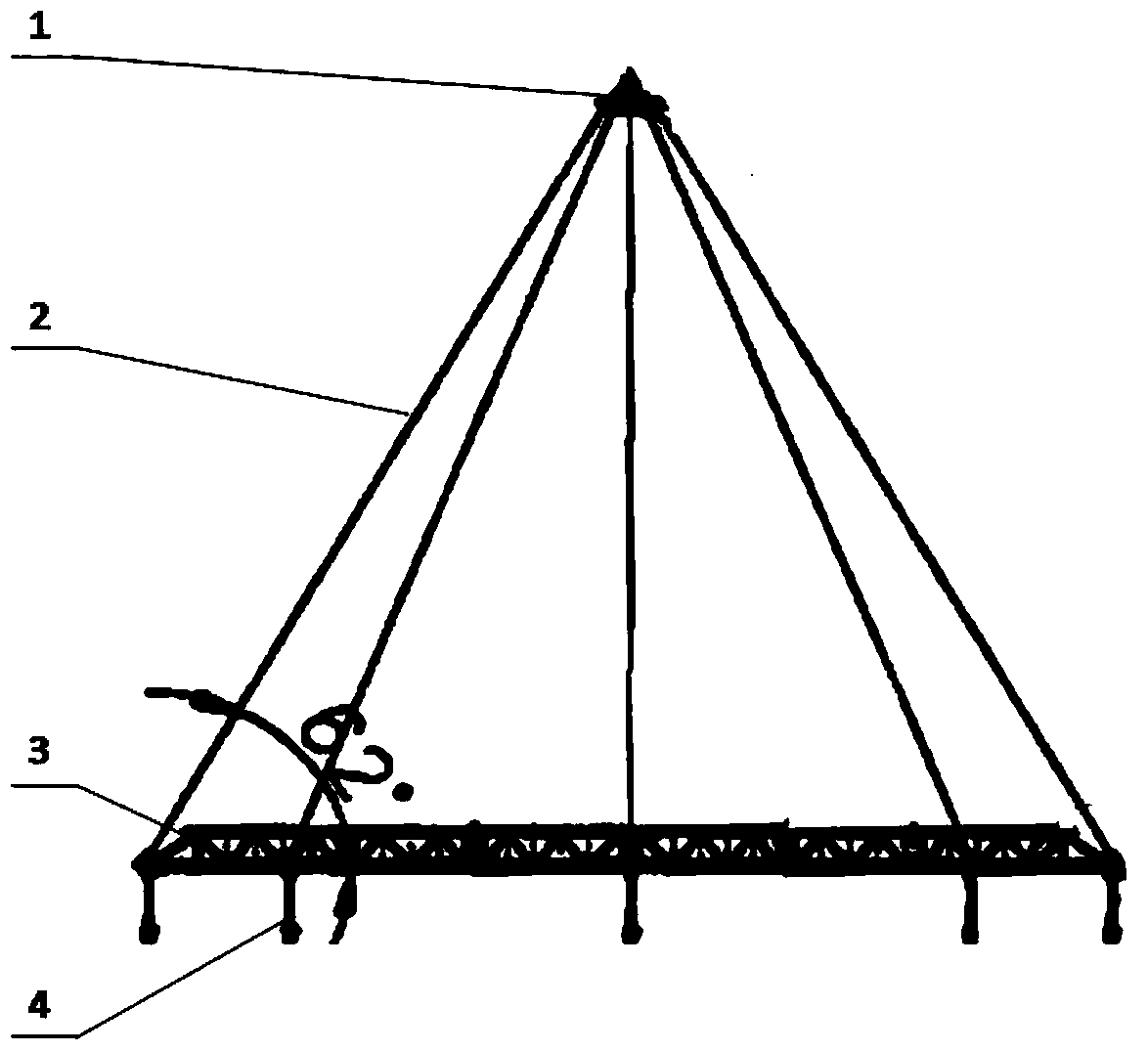

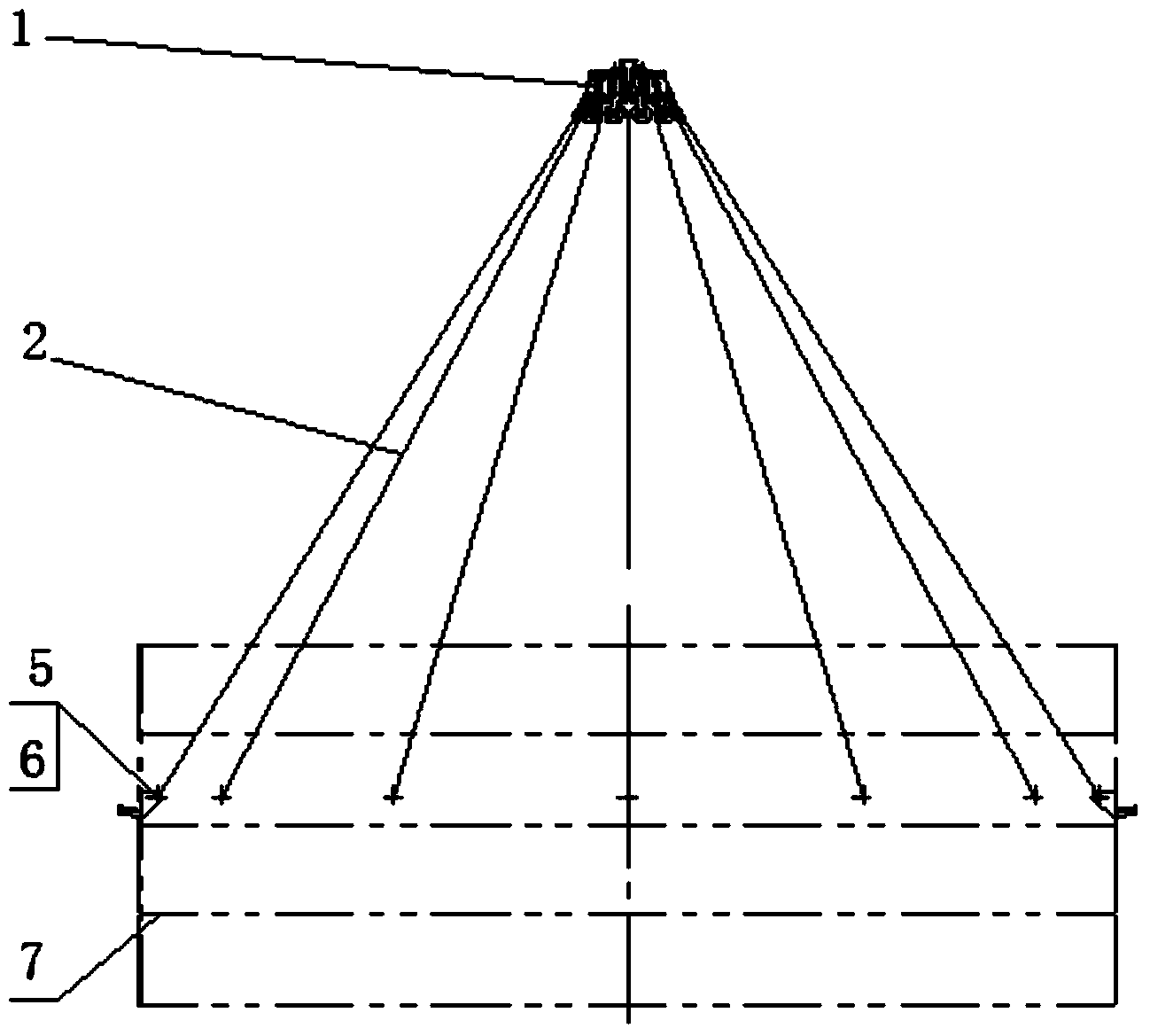

[0023] Such as figure 2 with image 3 As shown, a nuclear power plant steel containment module self-balancing hanger according to the present invention mainly includes a distributor 1, a steel wire rope 2, a pulley lifting point 5, and a fixed lifting point 6.

[0024] There are multiple pulley suspension points 5, for example: 9 in total. There are 3 fixed hanging points 6. The pulley lifting point 5 and the fixed lifting point 6 are both arranged on the steel containment module 7 .

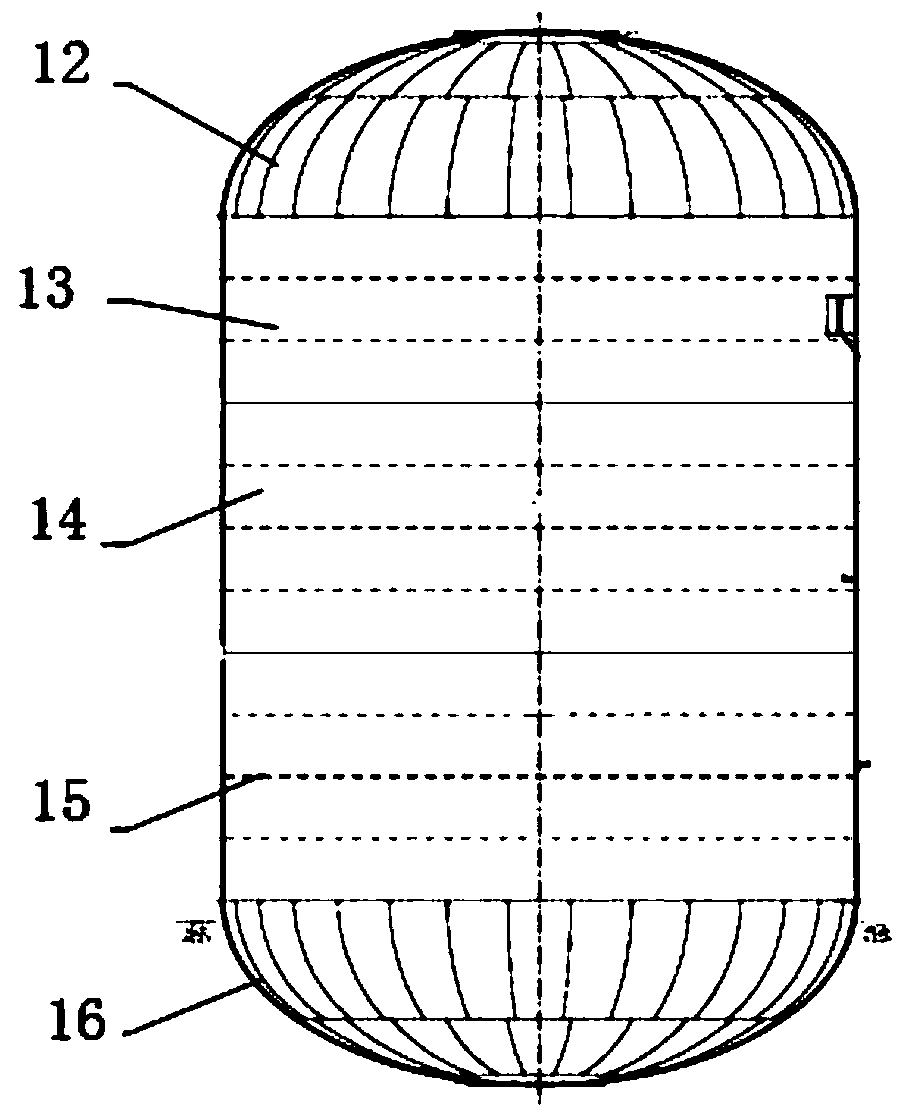

[0025] Such as figure 1 As shown, the steel containment module 7 can be the top head 12 , the first ring segment 13 , the second ring segment 14 , the third ring segment 15 or the bottom head 16 . Three fixed lifting points 6 are arranged on the steel containment module 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com