Connection structure of steel structure and precast concrete slab

A technology of prefabricated concrete slabs and connecting structures, applied in building components, building structures, walls, etc., can solve problems such as affecting the quality of walls and prone to cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

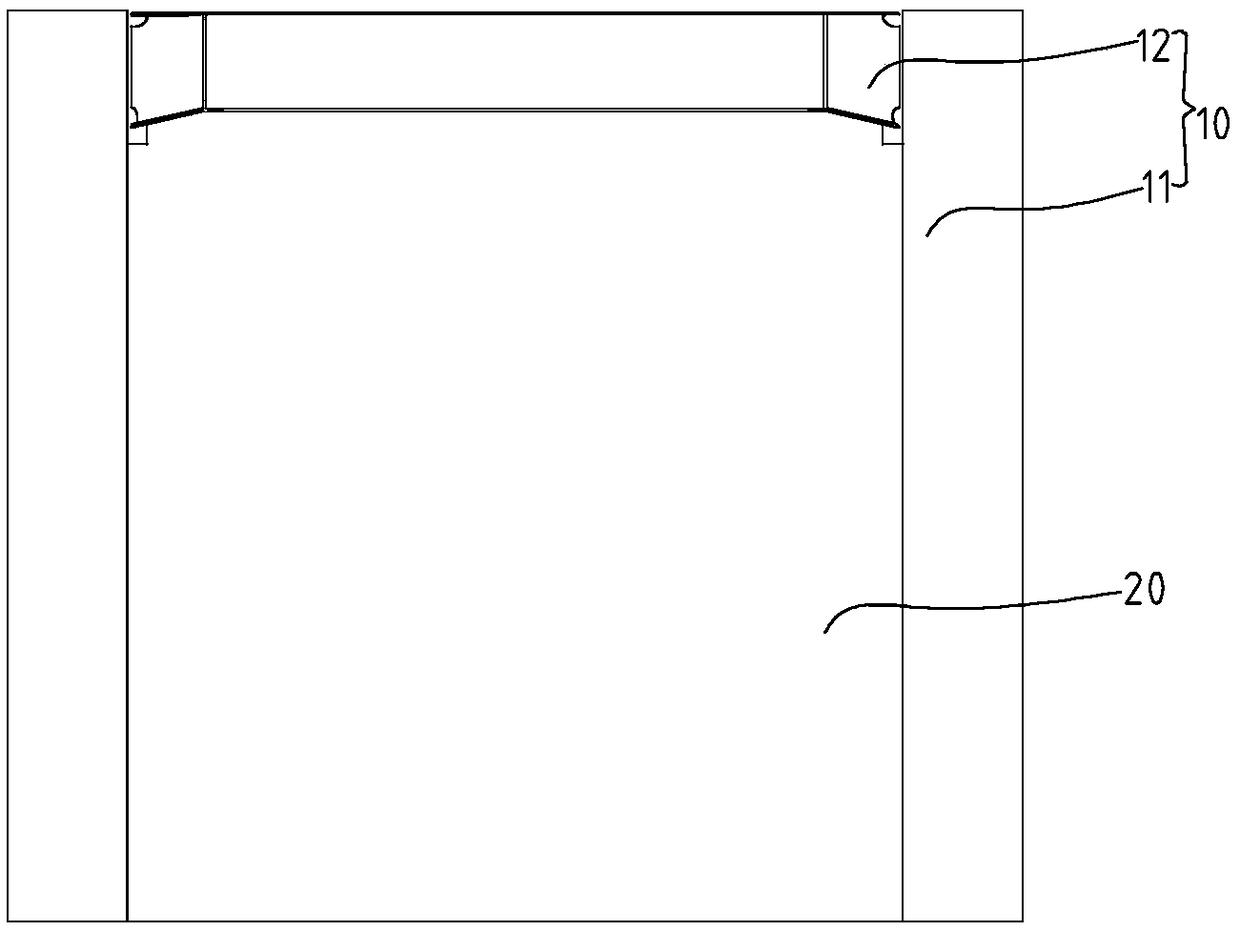

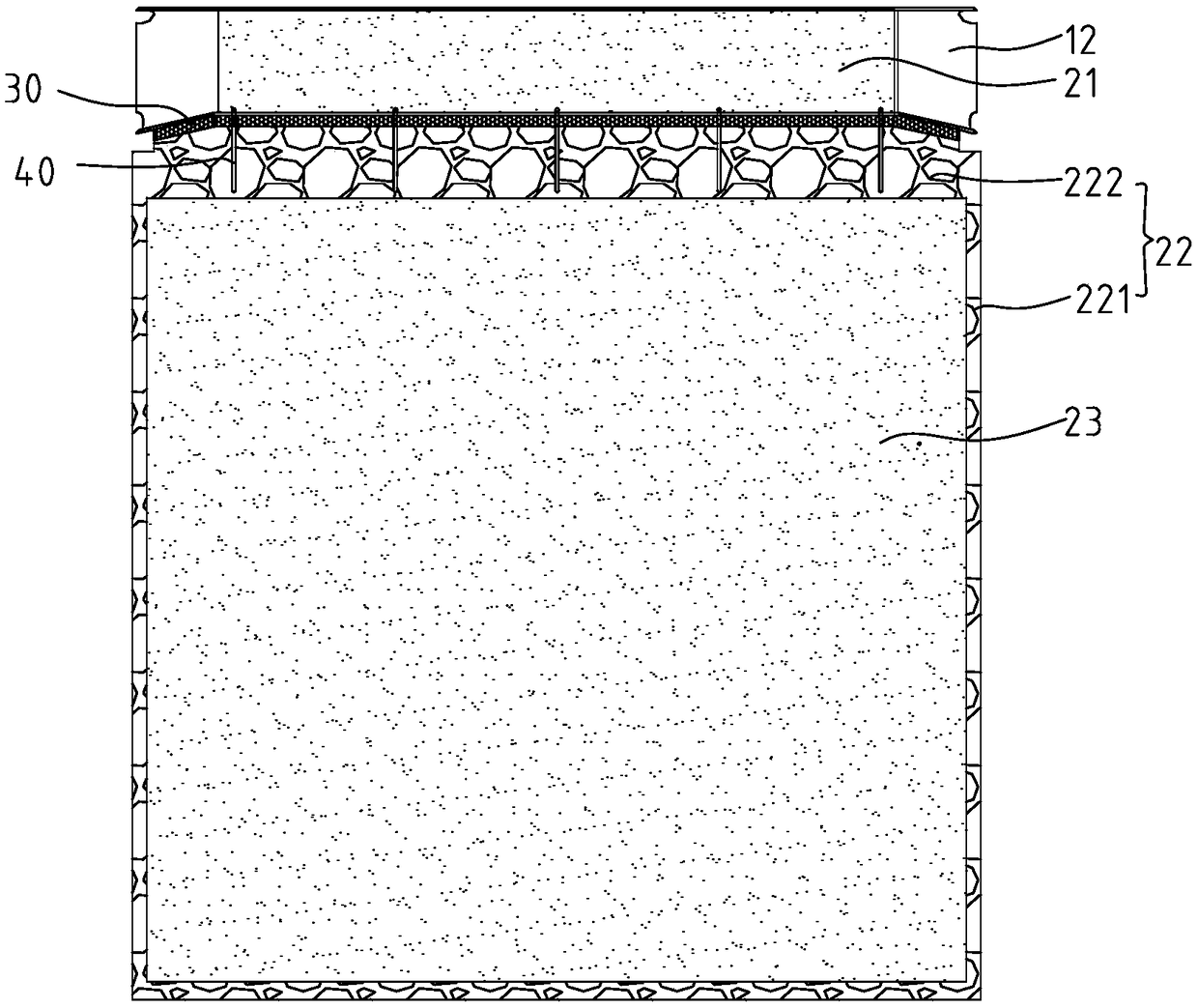

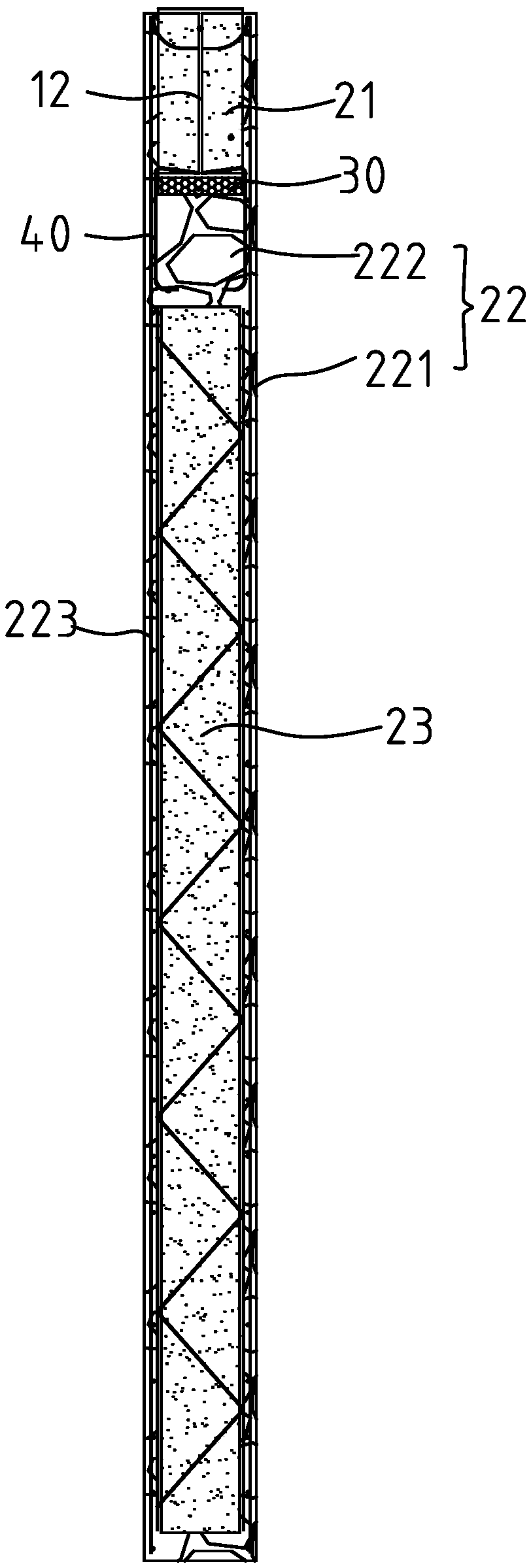

[0010] A connection structure between a steel structure and a precast concrete slab. The steel structure 10 includes a column 11 and a beam 12, wherein the end face of the beam 12 is fixed on the column 11, and the beam body of the beam 12 is placed inside the precast concrete slab 20. The prefabricated concrete slab 20 includes a foamed concrete layer 21 and a reinforced concrete layer 22, the foamed concrete layer 21 is filled around the beam 12, the reinforced concrete layer 22 is wrapped around the foamed concrete layer 21 and the beam 12, and the beam 12 is positioned below it An elastic transition layer 30 is set between the reinforced concrete layers 22.

[0011] The beam 12 of the steel structure and the precast concrete slab 20 are made into an integrated structure. The foam concrete layer 21 can allow the beam 12 to be deformed to a certain extent. , the elastic transition layer 30 can also buffer the load transmitted from the beam 12 to the precast concrete slab 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com