Prefabricated concrete ultra-thin type two-way stress fabricated steel bar truss composite floor slab

A prefabricated concrete slab and prefabricated concrete technology, which is applied to floors, building components, buildings, etc., can solve problems such as non-splicing, and achieve the effects of improving assembly accuracy, reducing formwork work, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

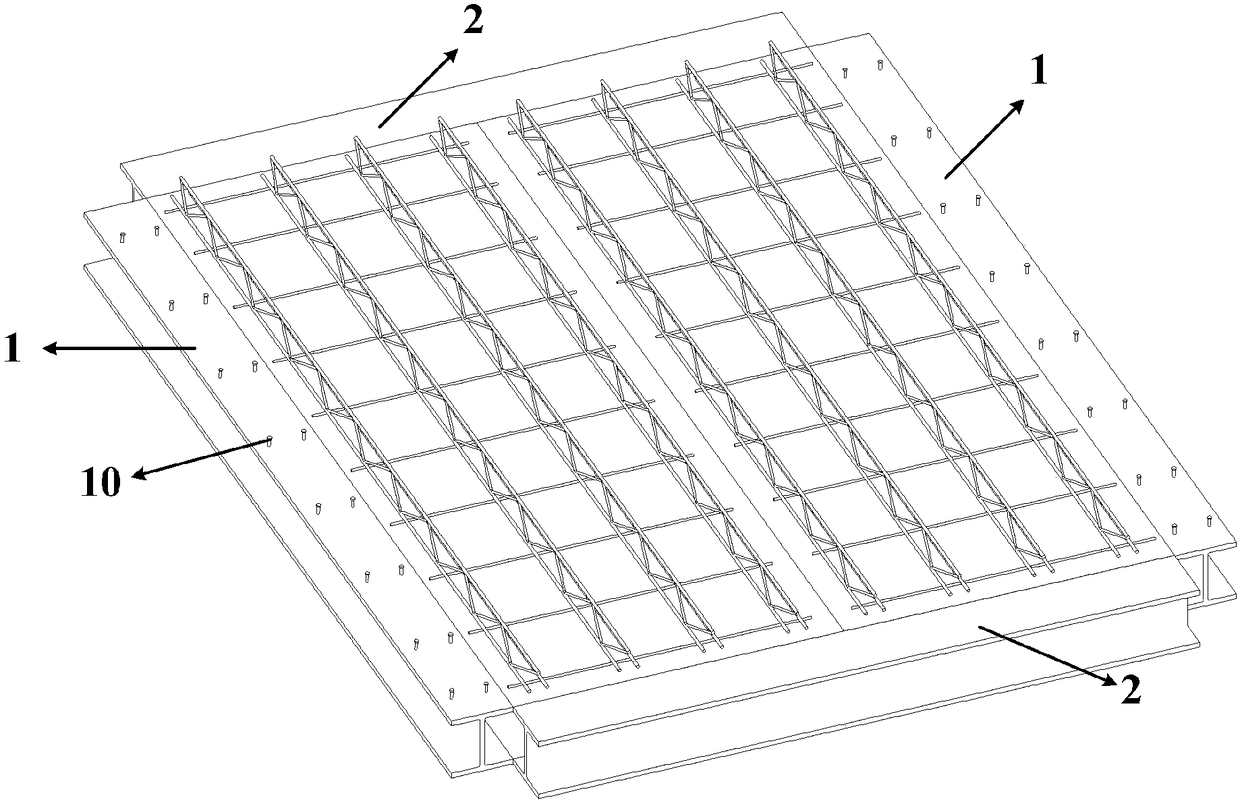

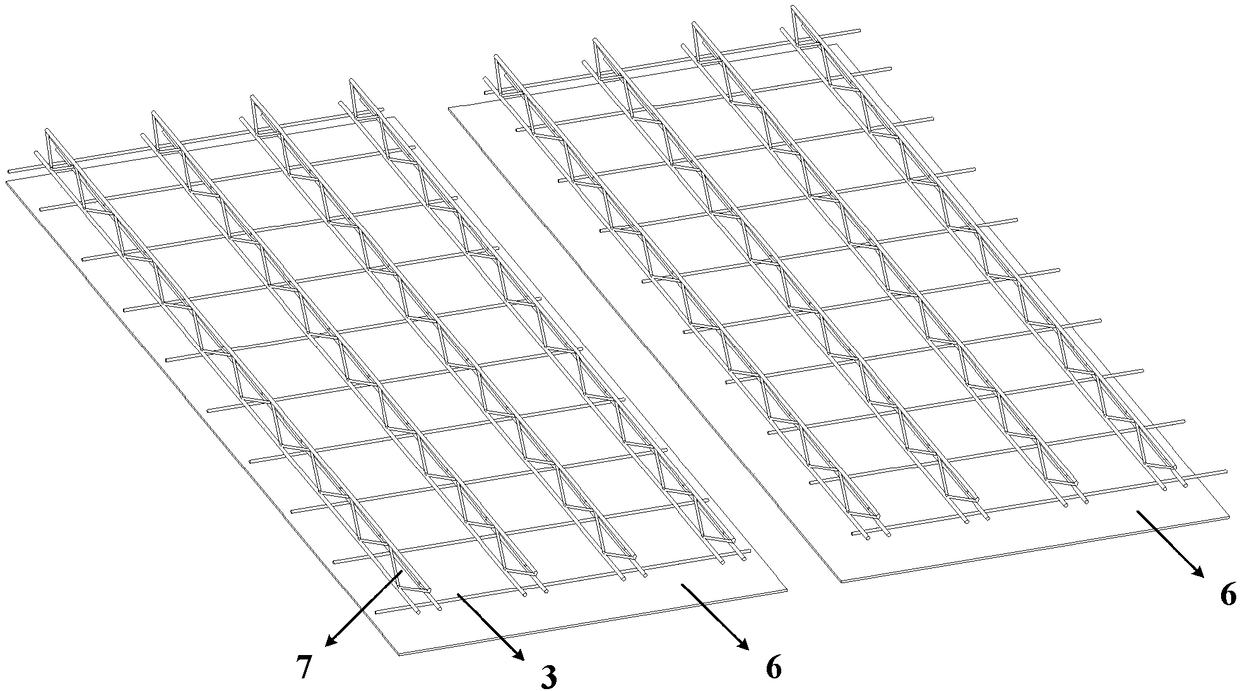

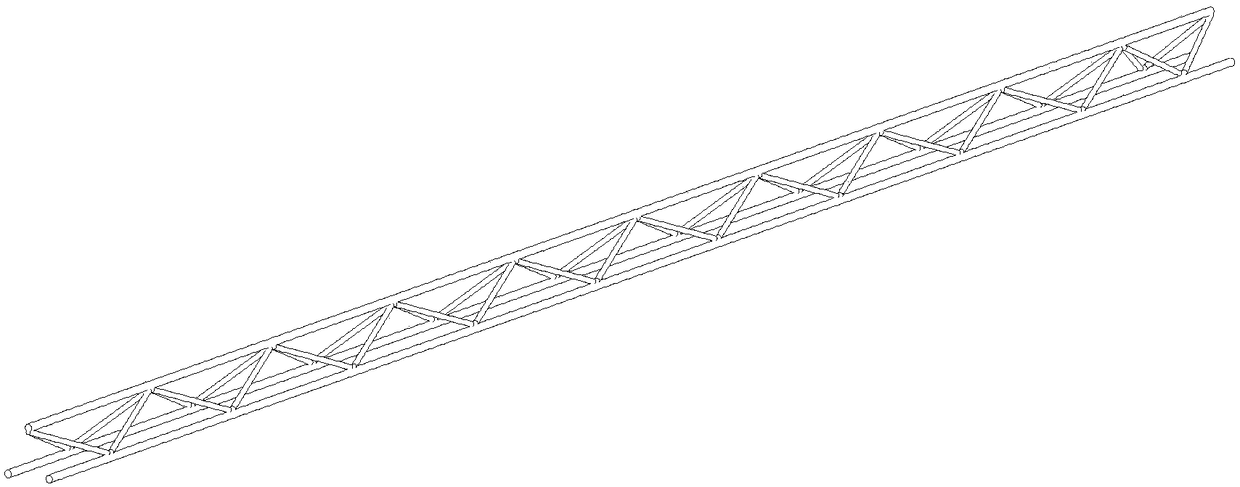

[0030] as attached figure 1 , 2 , 4, 5, and 7, the precast concrete ultra-thin two-way loaded reinforced truss laminated floor is composed of beams, studs, temporary supports, connecting plates, triangular steel trusses, prefabricated short bars, and precast concrete slabs ; The basic unit of the precast concrete ultra-thin two-way stressed assembled reinforced truss laminated floor includes a transverse I-shaped beam (1), a longitudinal I-shaped beam (2), a temporary support (4) and a prefabricated concrete slab layer (6).

[0031] as attached figure 1 As shown, the laminated floor beam includes a transverse I-shaped section beam (1) and a longitudinal I-shaped section beam (2). The upper and lower ends of the connecting plate (5) are welded on the transverse I-shaped cross-section beam (1). The studs (10) are welded on the upper surface of the upper flange of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com