A prefabricated large modular composite beam-slab structure with planar truss temporary support

A technology of temporary support and planar truss, which is applied in the direction of floor slabs, building components, building structures, etc., to achieve the effects of simple and convenient production, favorable layout, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

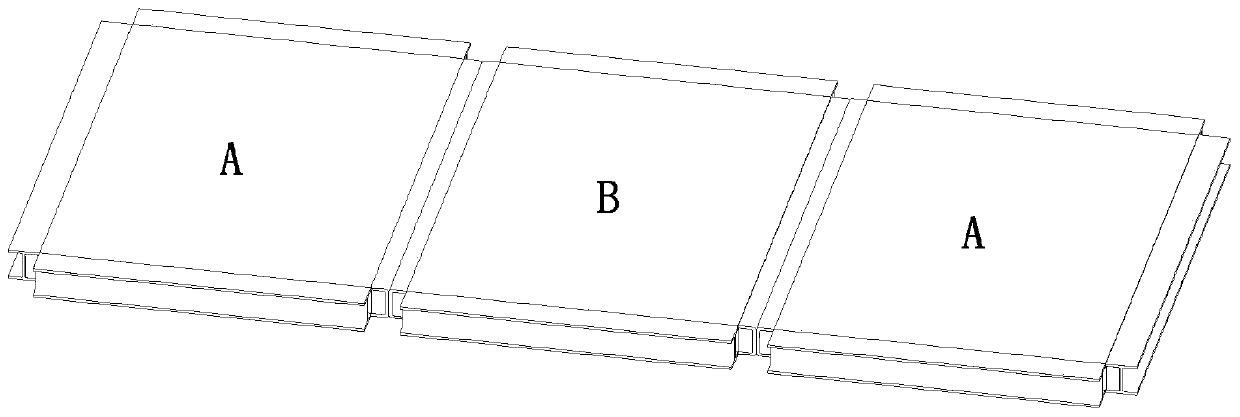

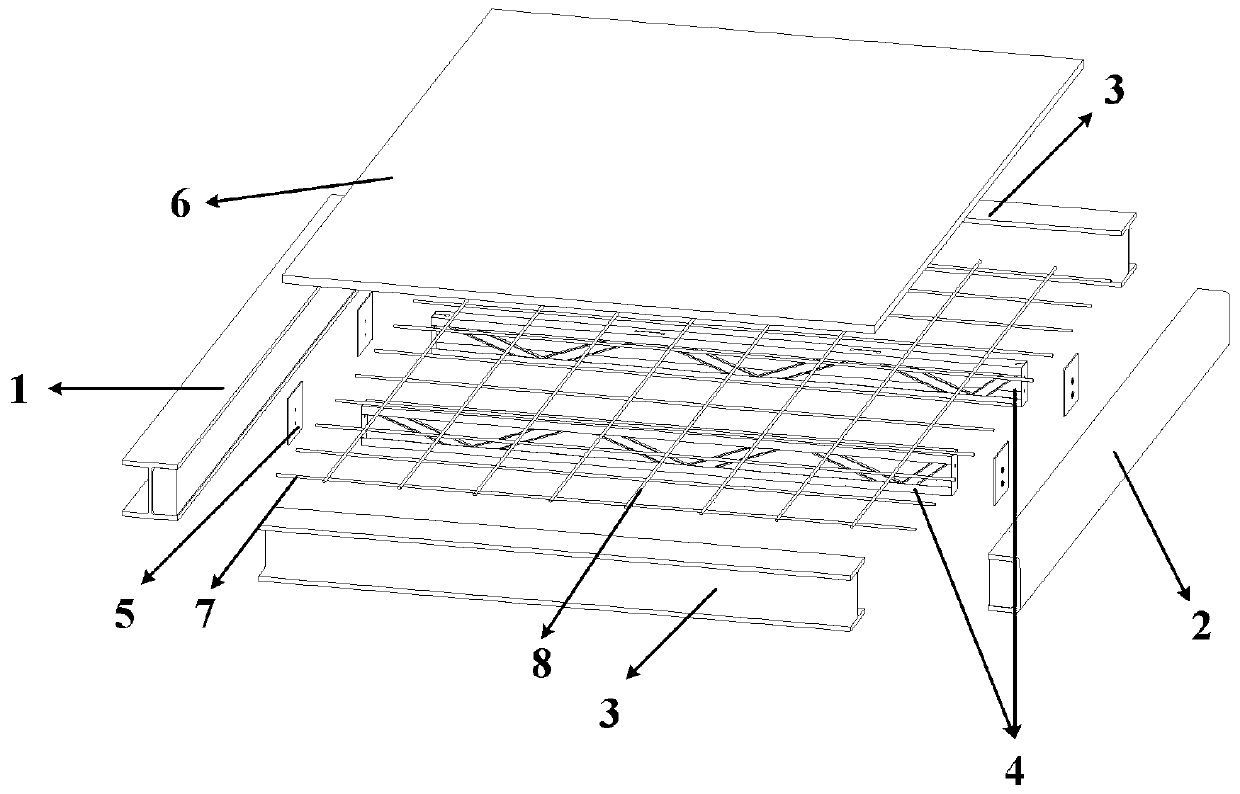

[0025] as attached figure 1 As shown, the assembled large module laminated beam-slab structure with temporary support of plane trusses is composed of temporary truss supports, steel beams, laminated floor slabs, steel mesh, and connecting plates; the temporary support with plane trusses The basic constituent units of the assembled large modular composite beam slab include side-span slab unit A and mid-span slab unit B; the side spans at both ends of the fabricated large module composite beam-slab with temporary support of plane trusses are side-span slabs Unit A, the second span connected to side span unit A adopts mid-span unit B, and the units in the rest of the span adopt mid-span unit B and are spliced with each other.

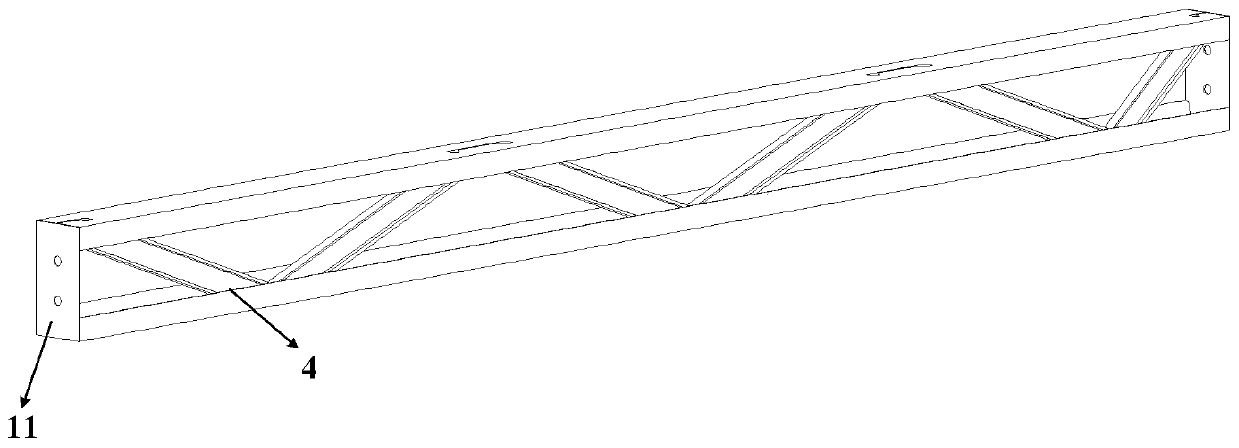

[0026] The longitudinal beams of the assembled composite beam-slab structure all adopt I-shaped cross-section beams (3). The side-span slab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com