Tension leveler for continuous caster

A technology of a tension leveler and a connecting pipe, applied in the field of steel casting, can solve the problems of inconvenient maintenance, reduced water pressure, no water cooling, etc., and achieve the effects of improving the cooling effect, enhancing the cooling effect, and reducing the difficulty of hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

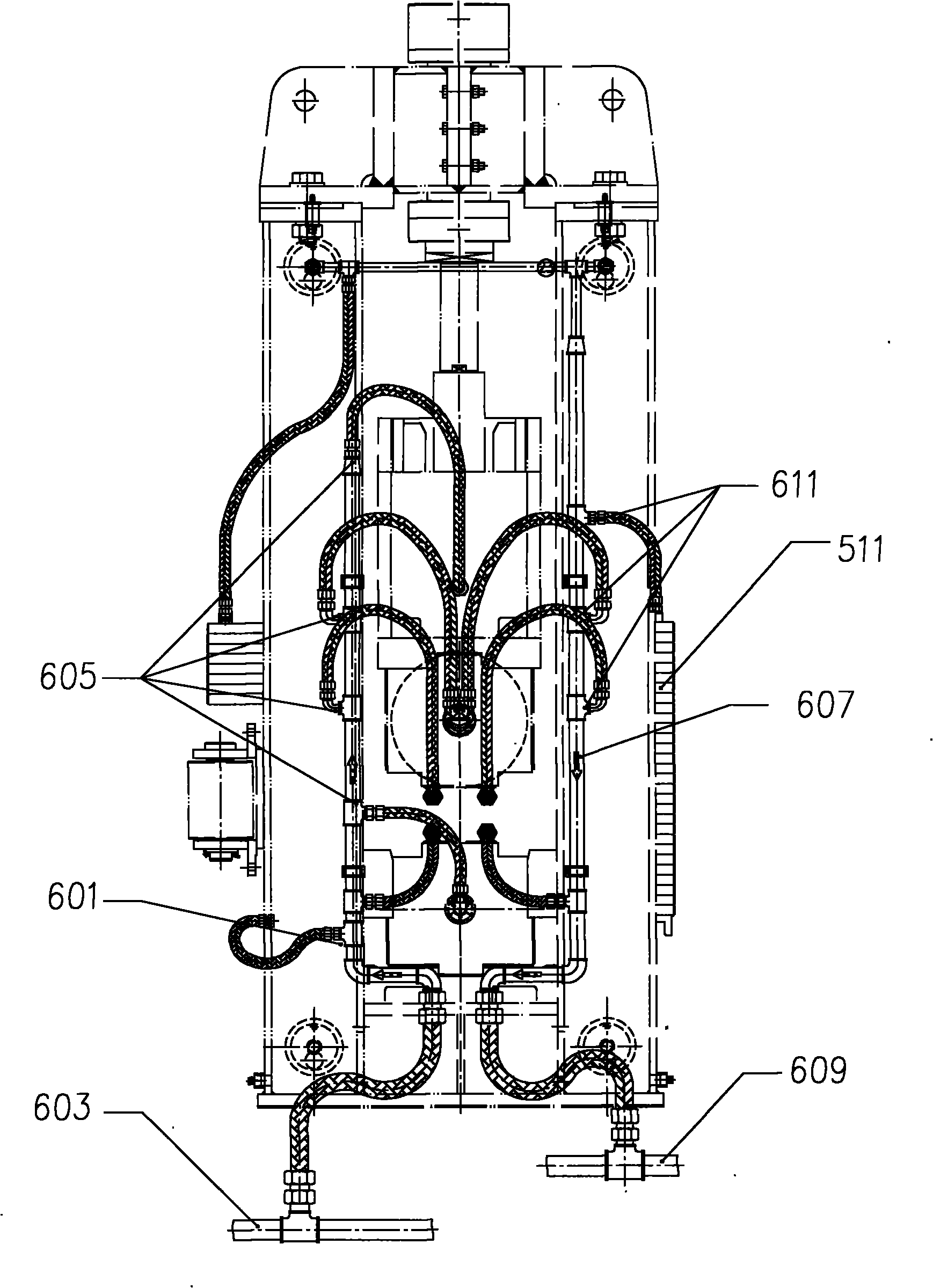

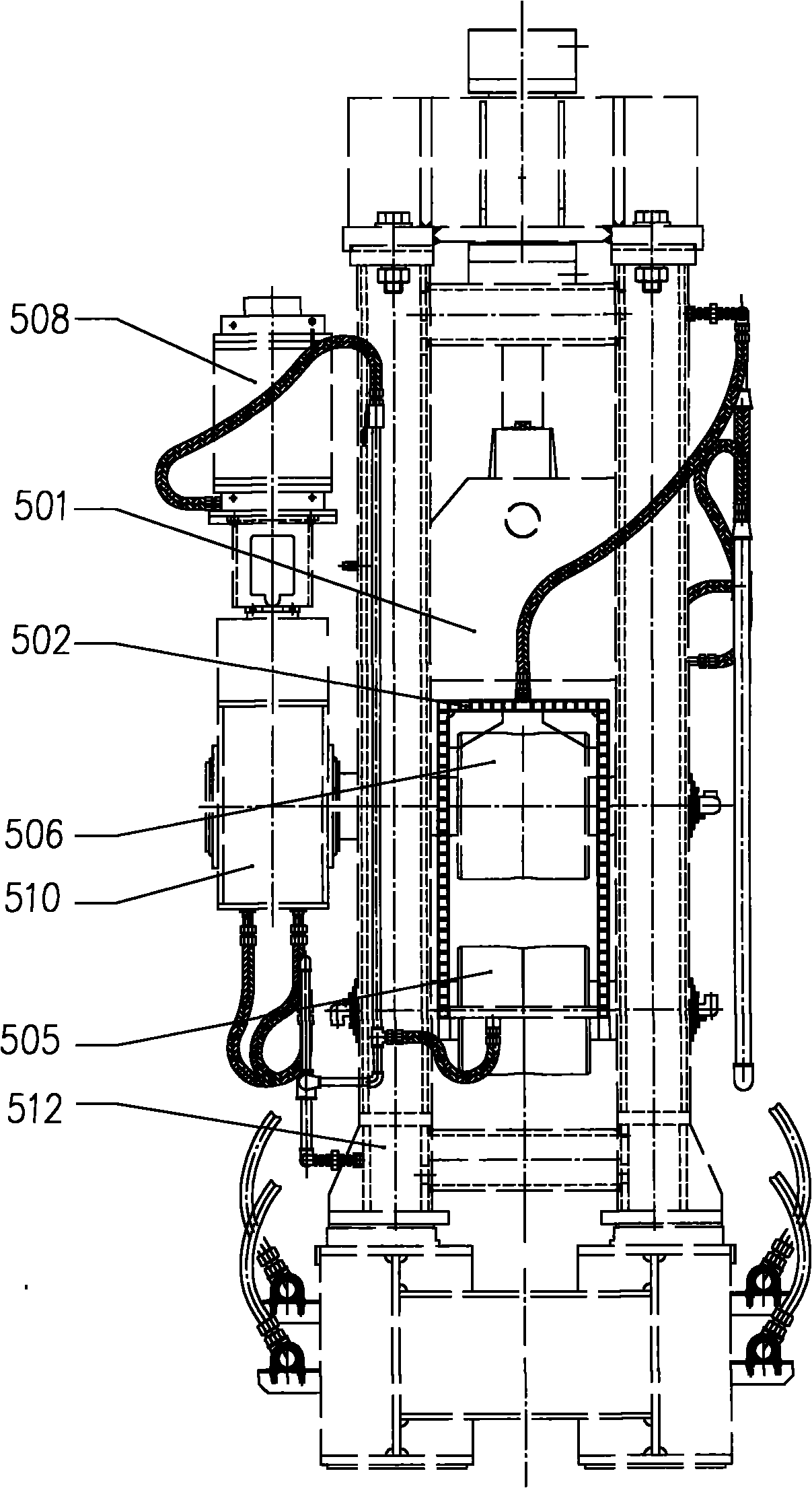

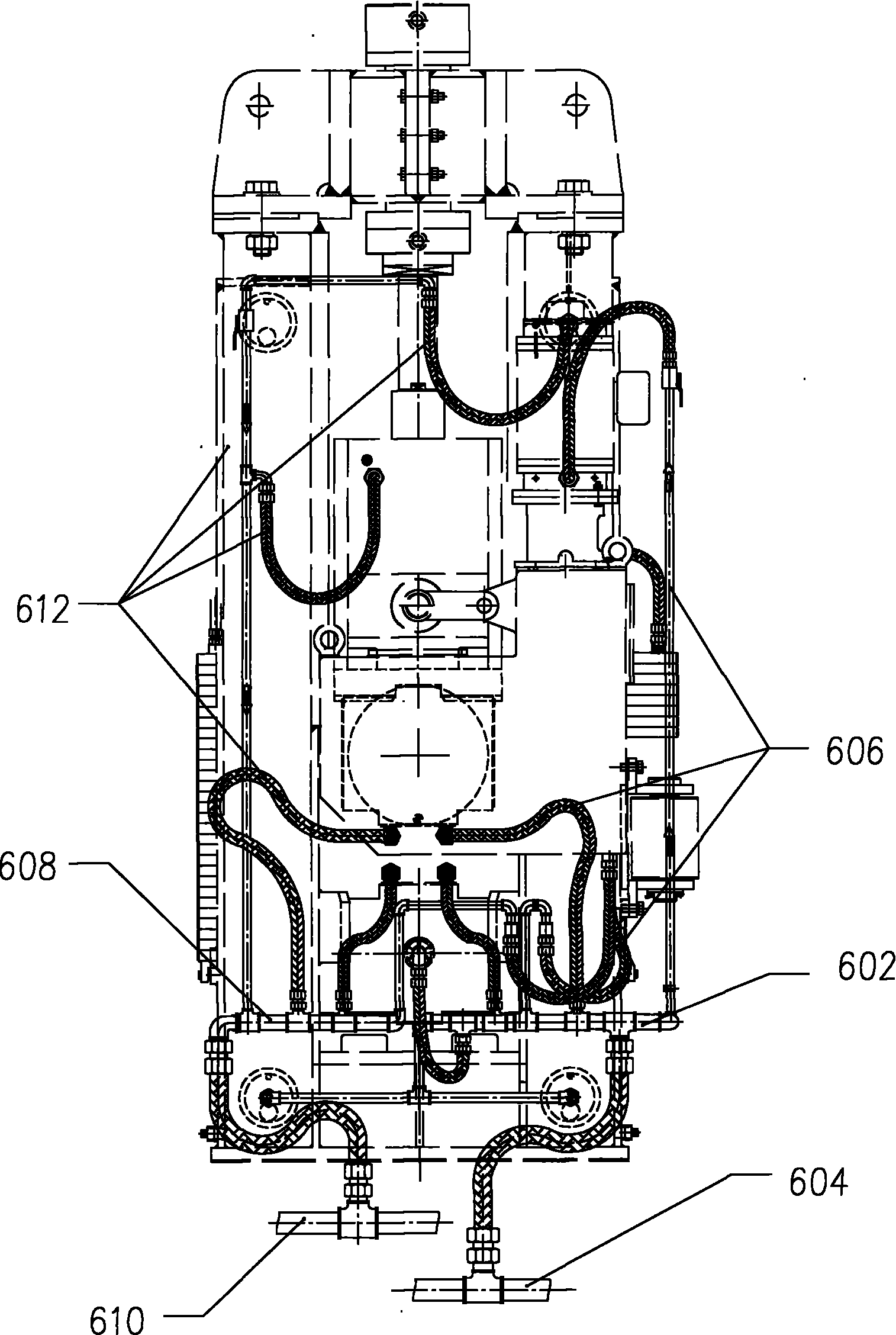

[0038] Embodiment one, see Figure 7 to Figure 9 , a water distribution device for a tension leveling machine, comprising a first column 1, a second column 2, a third column 3 and a fourth column 4, and various functional components arranged in a rectangular space surrounded by four columns, the four columns There are connecting pipes inside, and the connecting pipes are connected to each other; the first column 1 is provided with a general water inlet 5, the first column 1 and the second column 2 are water inlet columns, and the water inlet columns are connected. The second column 2 is connected through the water pipes 7 and 8; the third column 3 is provided with a total return water port 6, the third column 3 and the fourth column 4 are return water columns, and the return water columns are connected. The third column 3 and the fourth column The column 4 is connected through the water pipes 9 and 10; the water inlet column and the return water column are connected through th...

Embodiment 2

[0057] In the second embodiment, in the cooling device of the tension leveling machine, each water inlet and outlet are connected to each functional component through metal hoses, and the columns are connected through metal hoses. Determine the amount of cooling water required by each component by calculation, reasonably arrange the diameter and position of the inlet and outlet of each column, drill holes on each column and weld the pipe socket with the corresponding diameter; the inlet and outlet of all components to be cooled are respectively used The metal hose communicates with the pipe socket on the corresponding column. A regulating valve is installed on the metal hose to adjust the water flow online according to the working conditions of the tension leveler to ensure sufficient cooling of each functional component.

[0058] The water inlets and outlets are directly connected to the water inlet and return columns through metal hoses, which ensures the cooling effect of e...

Embodiment 3

[0059] Embodiment 3, in the tension leveling machine device, an exhaust valve is provided at the connection between the water inlet column 1, 2 and the return water column 3, 4. Wherein, an exhaust valve 512 is provided at the connection between the first column 1 and the second column 2 , and an exhaust valve 513 is provided at the connection between the third column 3 and the fourth column 4 . see Figure 10 , Exhaust valves 512 and 513 are respectively arranged on the water pipe 8 and the water pipe 9 .

[0060] During the process of cooling the components with cooling water, a large amount of water vapor will be generated, and a large amount of water vapor will stay in the cooling water pipe, which will cause poor water flow and is not conducive to the flow of cooling water. There is an exhaust valve to discharge a large amount of water vapor from the device in time, which helps to enhance the fluidity of cooling water.

[0061] In the device of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com