Partition direct hoisting construction method for hyperboloidal welded ball net rack

A construction method and technology of welding balls, which are applied in the directions of construction, building structure, and building materials, can solve problems such as the difficulty of hoisting super-large welded ball grid frames, ensure flatness and construction quality, reduce construction costs, and eliminate The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

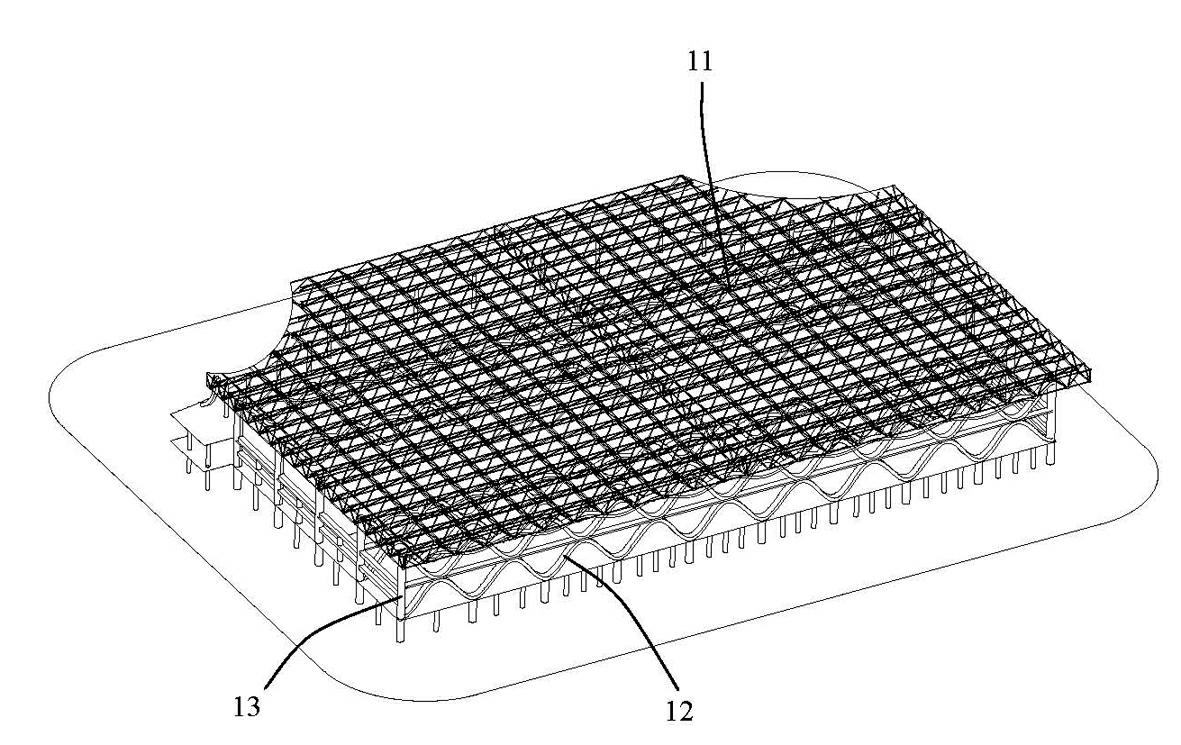

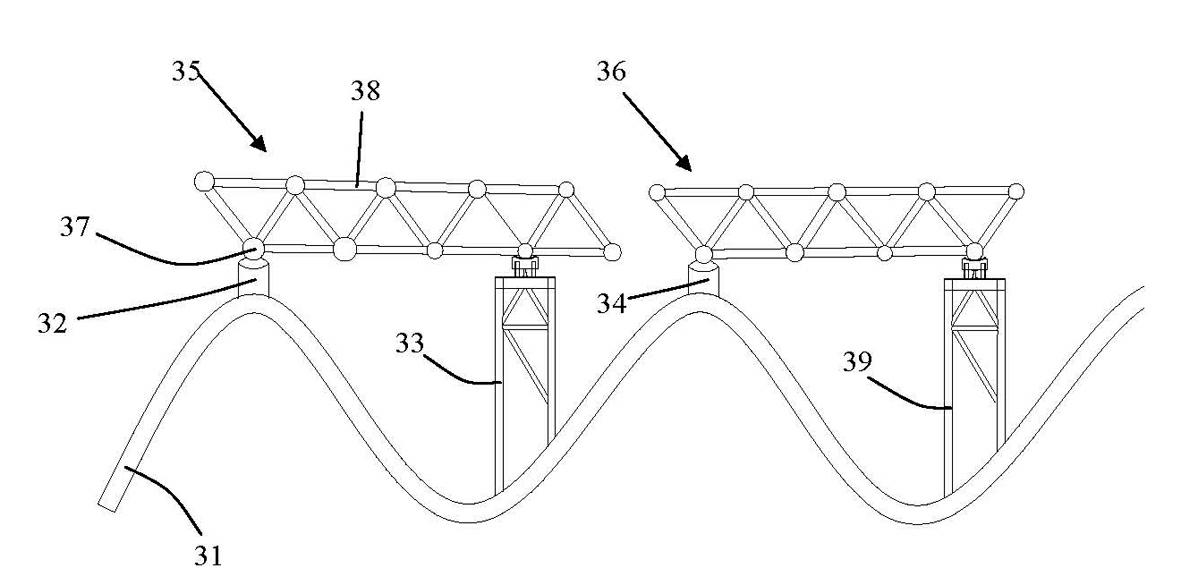

[0026] See figure 1 , which is a schematic diagram of a super-large roof grid structure system. The roof 11 is composed of a regular quadrangular pyramid grid. The supporting structure under the roof is mainly a ribbon 12 structure (ribbon-shaped curved steel beam structure) and distributed around The steel column 13 is made up of. Due to the large area of the roof 11, it is extremely inconvenient to hoist during construction. Therefore, the idea of dividing the grid structure of the entire roof 11 into multiple small-area grid units and hoisting them separately can greatly reduce the difficulty of hoisting the roof. .

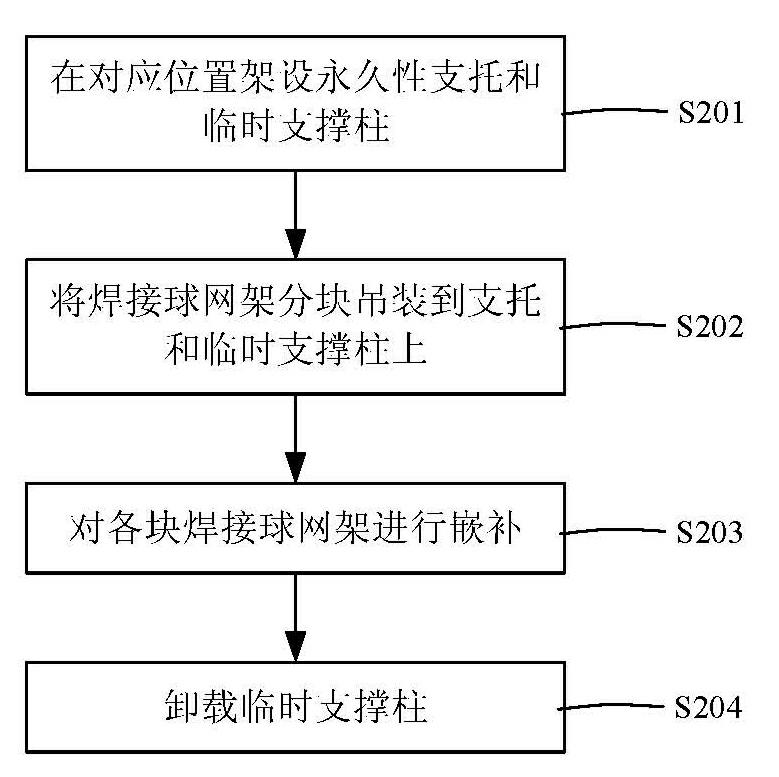

[0027] See figure 2 , which is a flow chart of an embodiment of the construction method for block-by-block direct hoisting of a hyperboloid welded ball net truss.

[0028] S201, erecting permanent supports and temporary support columns at co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com