Deep foundation pit concrete supporting structure with hoisting holes being pre-formed and construction method thereof

A technology for supporting structures and construction methods, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of mutual interference of working faces, overlapping construction procedures, and increased hoisting risks, so as to improve hoisting safety, hoisting stability and safety, The effect of reducing the risk of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

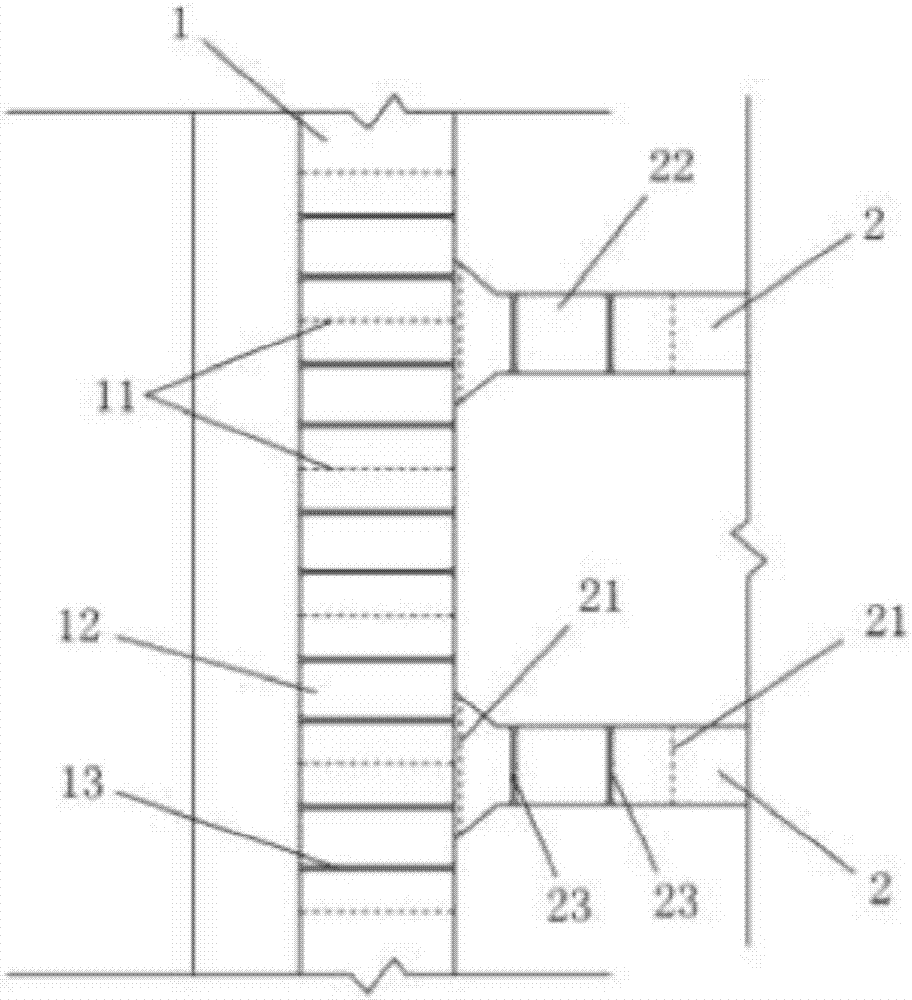

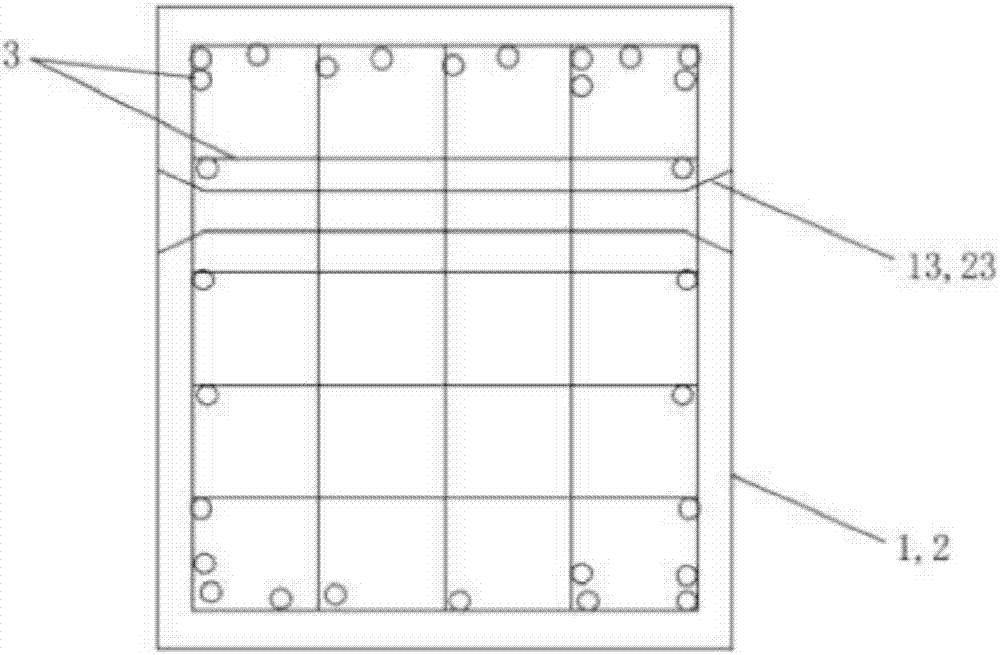

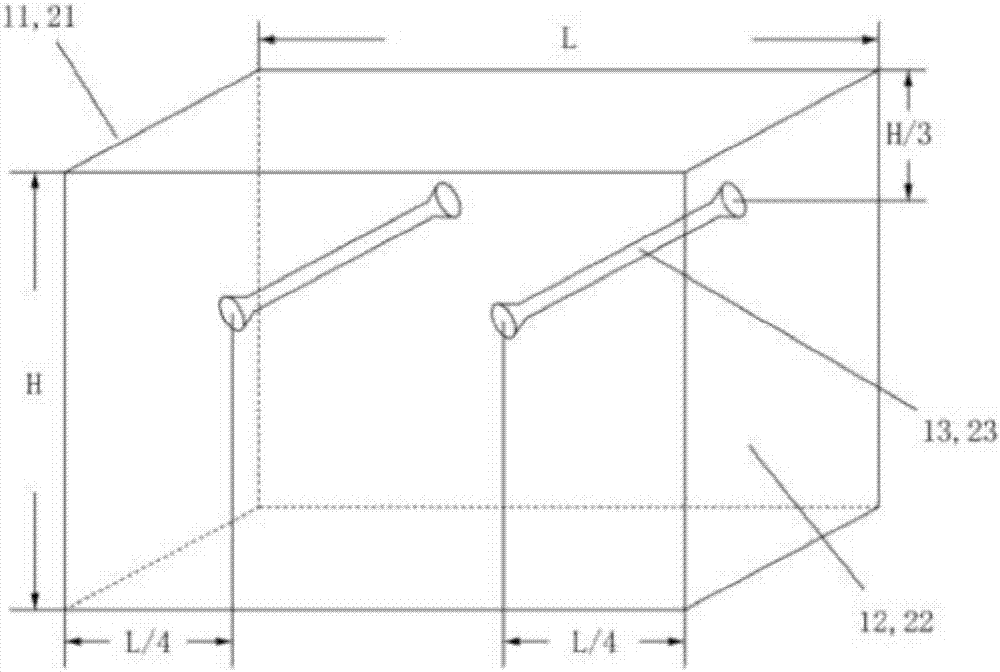

[0037] Such as Figure 1 to Figure 4 As shown, the present invention is an embodiment of the deep foundation pit concrete support structure with preset hoisting holes. The concrete support structure of the deep foundation pit includes concrete waist beams 1 and concrete supports 2 connected to each other. The concrete waist beam 1 has a plurality of waist beam pre-cut surfaces 11, and the plurality of waist beam pre-cut surfaces 11 divide the concrete waist beam 1 into two parts. There are a plurality of waist beam pre-cut sections 12, and each waist beam pre-cut section 12 is pre-embedded with a waist beam hoisting hole pipe 13 for passing a hoisting steel wire rope. Preferably, two waist beam hoisting hole pipes 13 are pre-embedded side by side along the length direction of the concrete waist beam 1 in each waist beam pre-cut section 12 . The waist beam hoisting hole pipe 13 is arranged on the top of the concrete waist beam 1 along the transverse direction of the concrete w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com