Blade hoisting equipment

A technology for hoisting equipment and blades, which is used in transportation and packaging, load hoisting components, and assembly of wind turbines, etc., can solve the problems of no oblique-inserted single-blade hoisting, long time for turning the impeller, and reduced installation efficiency of the unit. , to achieve the effect of reducing tooling development costs, increasing process diversity, and increasing hoisting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

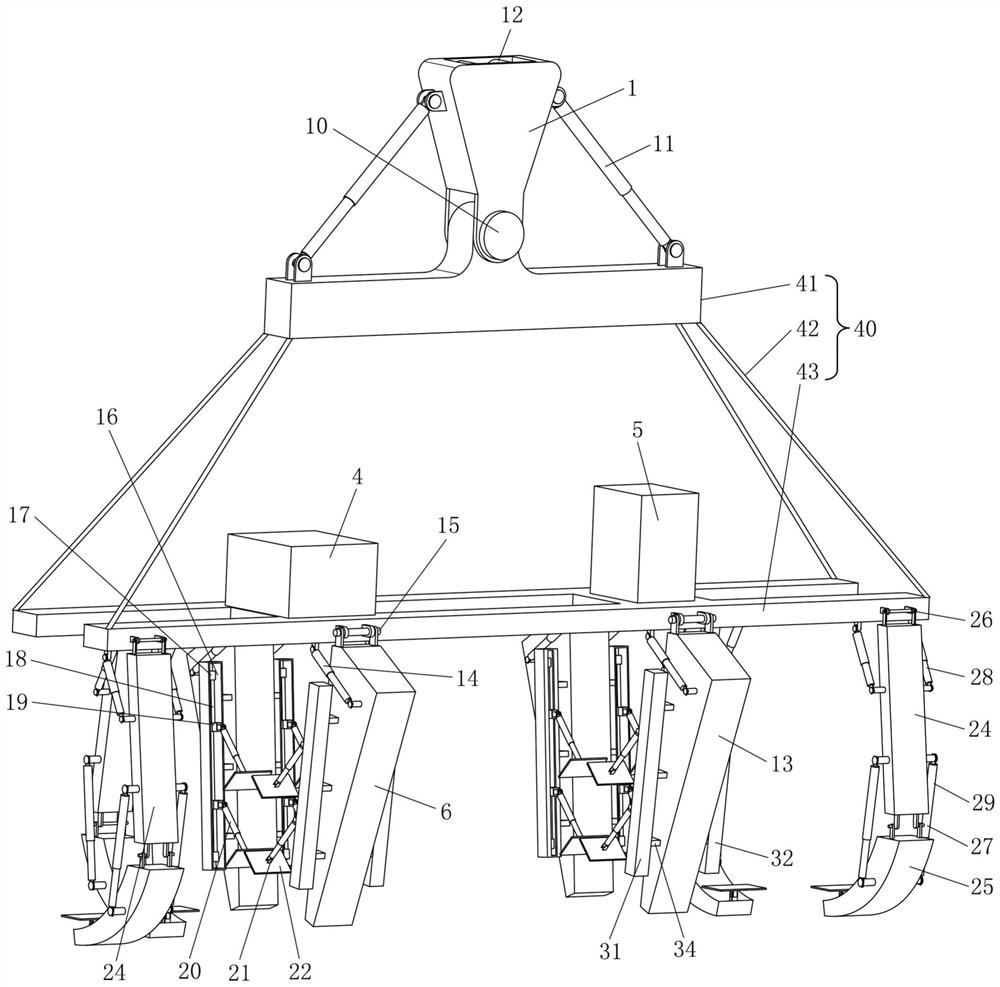

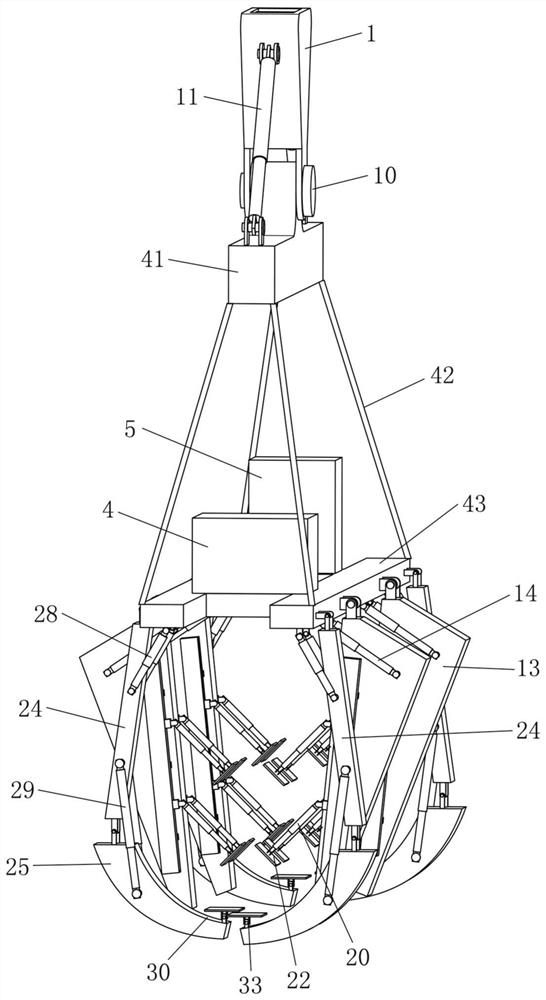

[0029] refer to figure 1 and figure 2 , the blade hoisting device according to the present invention may include: a suspension beam 1; a spreader frame 40; coupled to the suspension beam 1; a clamping mechanism, mounted on the spreader frame 40, and including A blade web clamp for clamping the position of the blade web and a blade leading edge support clamp for holding the position of the blade leading edge are arranged to clamp the blade in a state where the blade leading edge faces downward.

[0030] The blade web clamp may comprise at least one web clamping unit, and each web clamping unit comprises two web clamping arms disposed facing each other in the width direction of the spreader frame 40, with A clamping space is formed between the web clamping arms, and one end of each web clamping arm is pivotally coupled to the spreader frame 40, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com