Recyclable single-bundle post-tensioning non-bonding prestress underground diaphragm wall and construction method

A technology of underground diaphragm wall and construction method, which is applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems of rising, steel waste cost, etc., and achieve the effect of reducing consumption, reducing construction cost, and reducing difficulty and risk of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

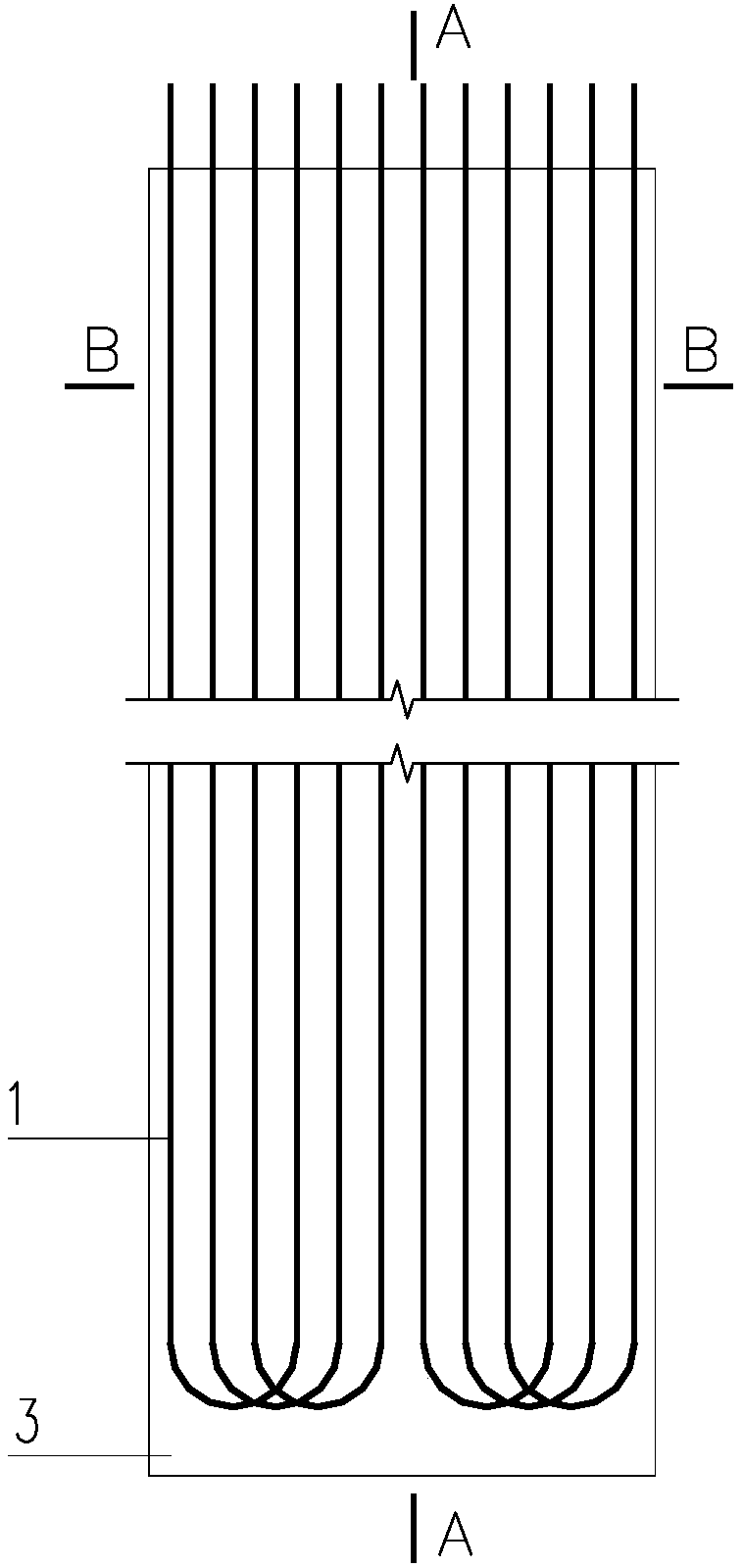

[0042] see Figure 1 to Figure 9 , this embodiment discloses a construction method for recyclable single-bundle post-tensioned unbonded prestressed underground diaphragm wall, including:

[0043] trench section excavation construction;

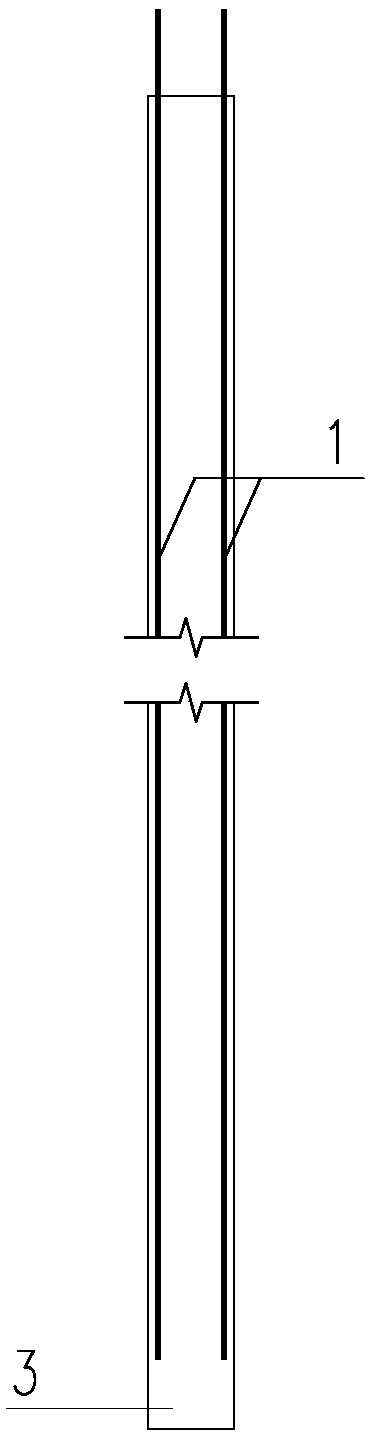

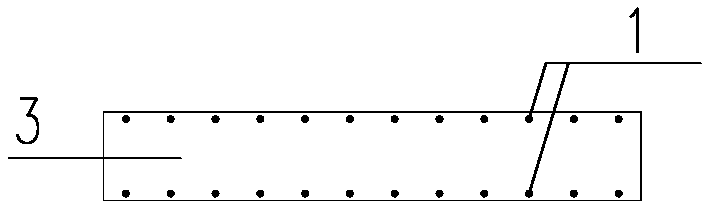

[0044] Hoist the steel cage 2 with several prestressed tendons 1 into the groove section, each prestressed tendon 1 is installed on the reinforced cage 2 in a U-shape, and the two ends of the prestressed tendons 1 protrude from the proposed underground continuous wall section 3 Each prestressed tendon 1 is an unbonded prestressed tendon 1, and the unbonded prestressed tendon 1 includes an outer casing 101 and a steel strand 102 arranged in the outer casing 101; a reinforcement cage 2 The overall design reinforcement of the prestressed tendon 1 is determined according to the internal force of the underground diaphragm wall during the construction of the underground structure, and the design of the reinforcement cage 2 is determined according t...

Embodiment 2

[0062] read on Figure 1 to Figure 9 , this embodiment discloses a recyclable single-bundle post-tensioned unbonded prestressed underground diaphragm wall, comprising several underground diaphragm wall sections 3, adjacent underground diaphragm wall sections 3 are connected by joints, and the underground diaphragm wall sections 3 include Reinforcement cage 2 and several prestressed tendons 1, each prestressed tendon 1 opening is U-shaped and installed on the reinforcement cage 2, the two ends of the prestressed tendons 1 protrude from the top surface of the underground continuous wall section 3, each The prestressed tendon 1 is an unbonded prestressed tendon 1 , and the unbonded prestressed tendon 1 includes an outer casing 101 and a steel strand 102 arranged in the outer casing 101 .

[0063] In the use stage after the construction of the underground structure is completed, the internal force on the underground diaphragm wall is reduced. Even if the steel strand 102 in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com