Tooling suitable for high pier and large span continuous rigid frame extra heavy 0 # bracket preloading

A large-span, rigid-frame technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as time-consuming, labor-intensive, affecting construction progress, cumbersome procedures, etc., to reduce construction investment, save construction time, and ensure construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

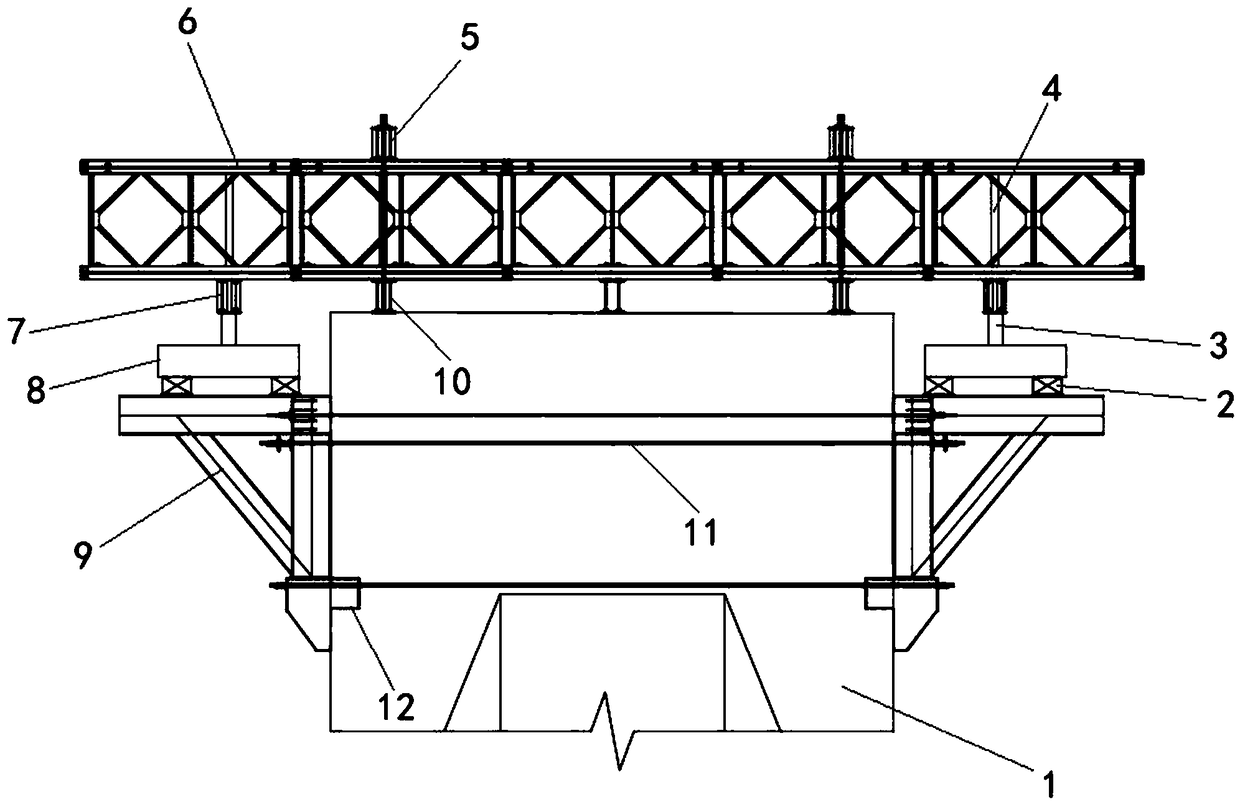

[0011] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is further described, and the definition of each label among the figure is: beam body 1, drop spacer 2, jack 3, reinforcing vertical bar 4, reaction force pole beam 5, Bailey beam 6, Reaction force top beam 7, distribution beam 8, bracket 9, pad beam 10, pre-embedded rebar 11, and reserved holes 12 in the pier body.

[0012] The present invention includes a Bailey beam 6 and a jack 3 . The Bailey beam 6 is fixed on the top of the beam body 1 through a plurality of reinforcing vertical rods 4 . A plurality of brackets 9 are fixed to the side wall of the beam body 1 through the reserved holes 12 of the pier body and the pre-embedded screw steel 11 . A jack 3 is provided between each bracket 9 and the Bailey beam 6 . The top of the Bailey beam 6 is provided with a counter force pole beam 5, and the reinforcing vertical rod 4 passes through the counter force pole beam 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com