High pier zero block counter-force pre-pressing method based on combined bracket

A zero-block, combined technology, used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of large influence of bearing platform geometric size, small applicable surface, and lack of versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

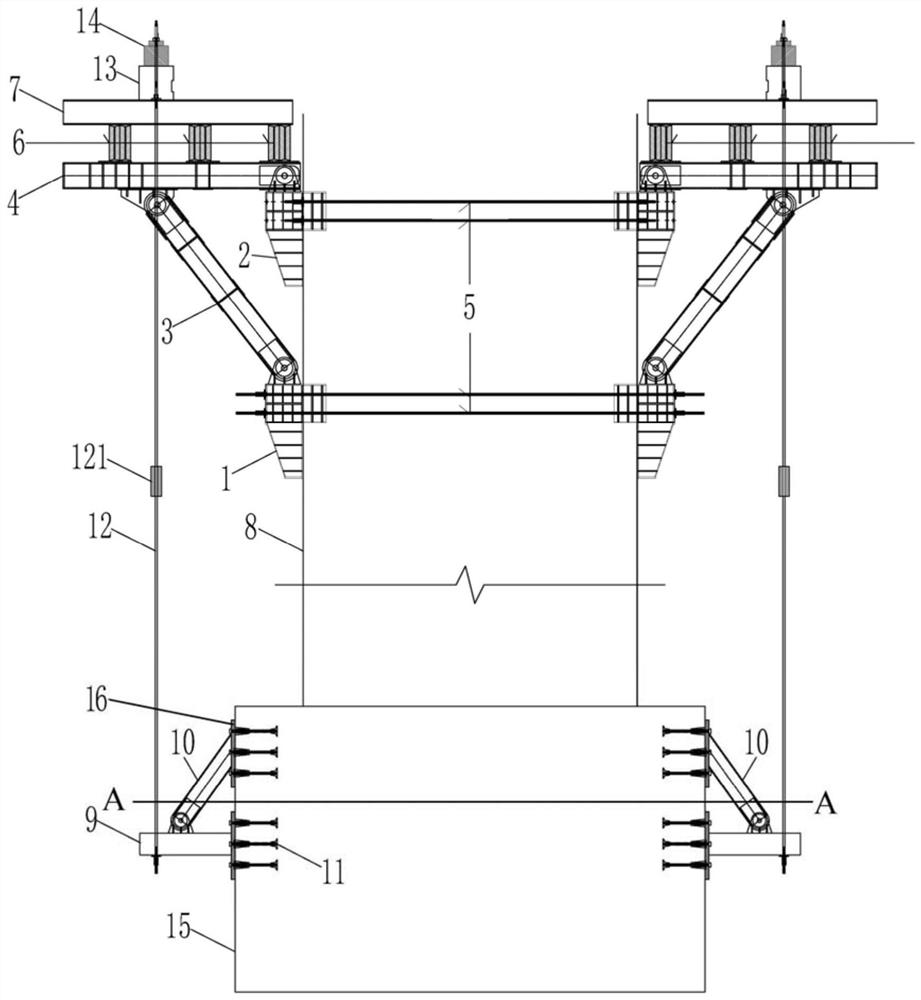

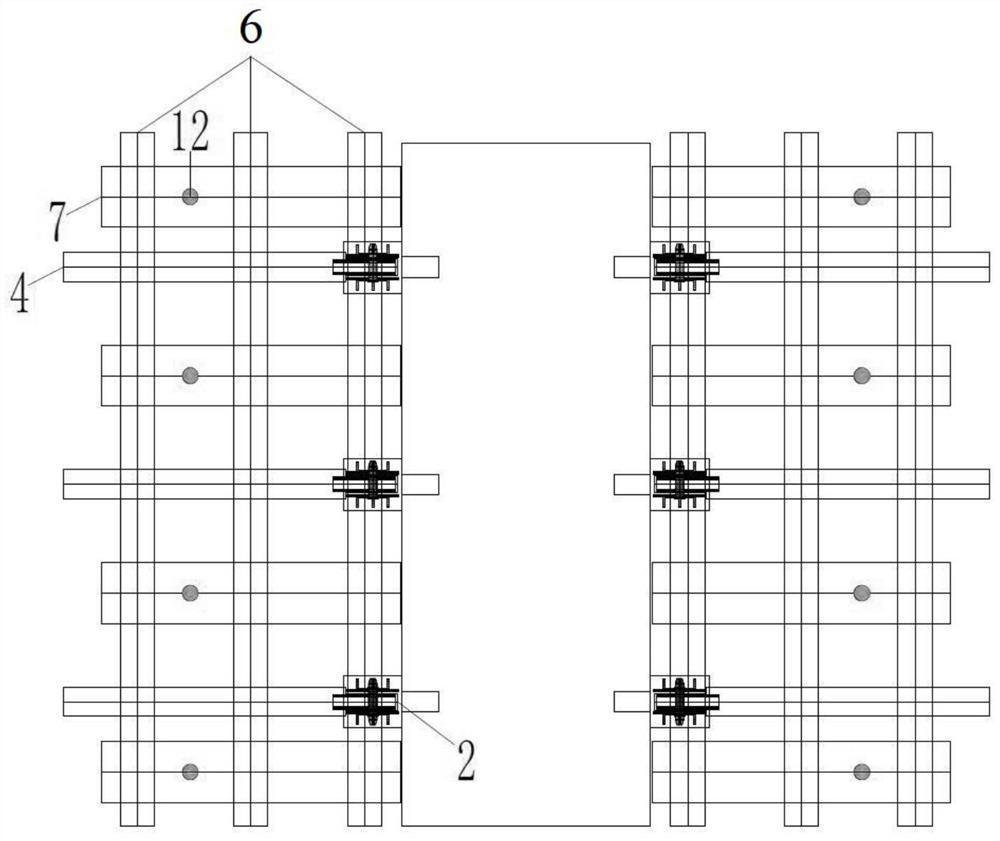

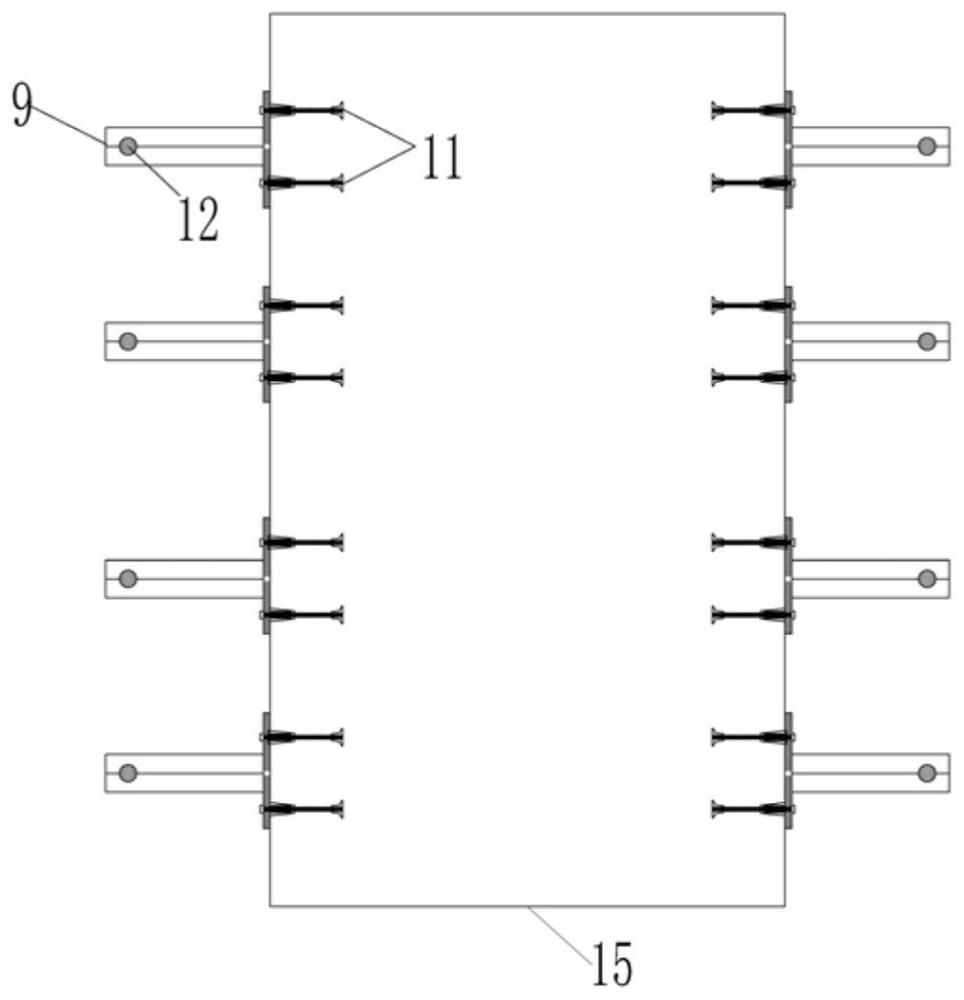

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] A combined bracket adapted to the zero block of high piers provided by the present invention includes at least an upper shear key 2, a lower shear key 1, a bracket diagonal brace 3 and a bracket straight brace 4, and the structure is as follows figure 1 and figure 2 As shown, the lower shear keys are provided with an even number of more than four, and the lower shear keys are evenly distributed on the left and right sides of the pier body and their positions correspond to each other. Between the two lower shear keys corresponding to the left and right positions It is connected with a horizontal tie rod 5 pre-buried in the pier body, and the lower shear key is fixed on the pier body through the horizontal tie rod. The upper shear keys are provided with an even number and are more than four, and the upper shear keys are evenly distributed on the left and right sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com