Container ship washing tower subsection dividing and installing method

A technology for container ships and installation methods, which is applied to ships and other directions, can solve problems such as the inability to install scrubber equipment and exhaust pipe segmental manufacturing accuracy, and achieve the effect of reducing the risk of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention is further described below in conjunction with specific embodiments:

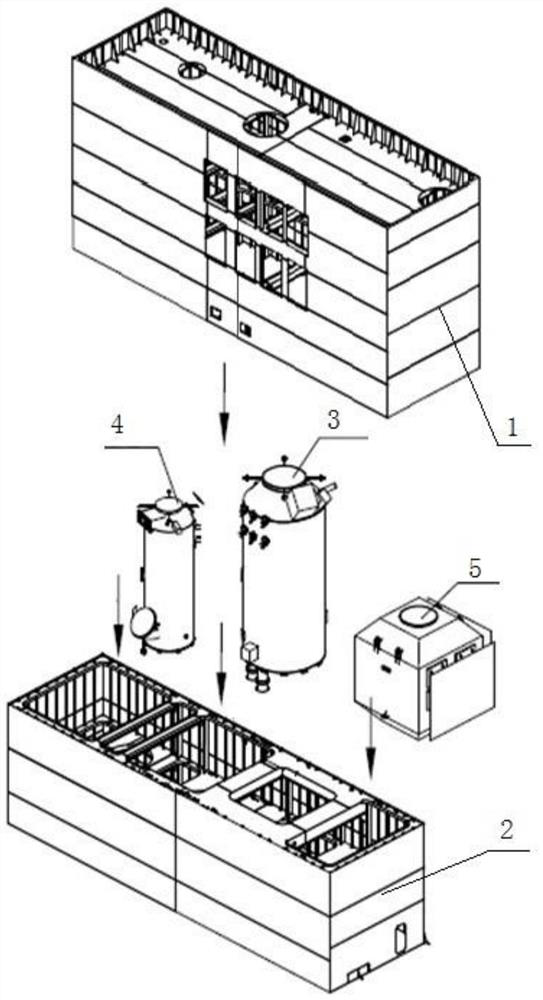

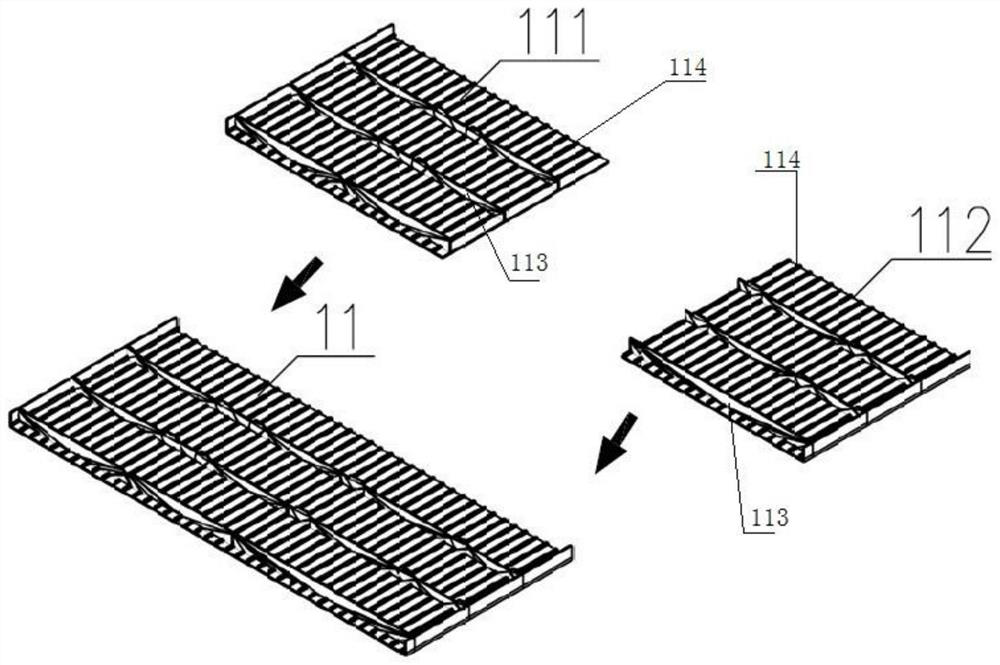

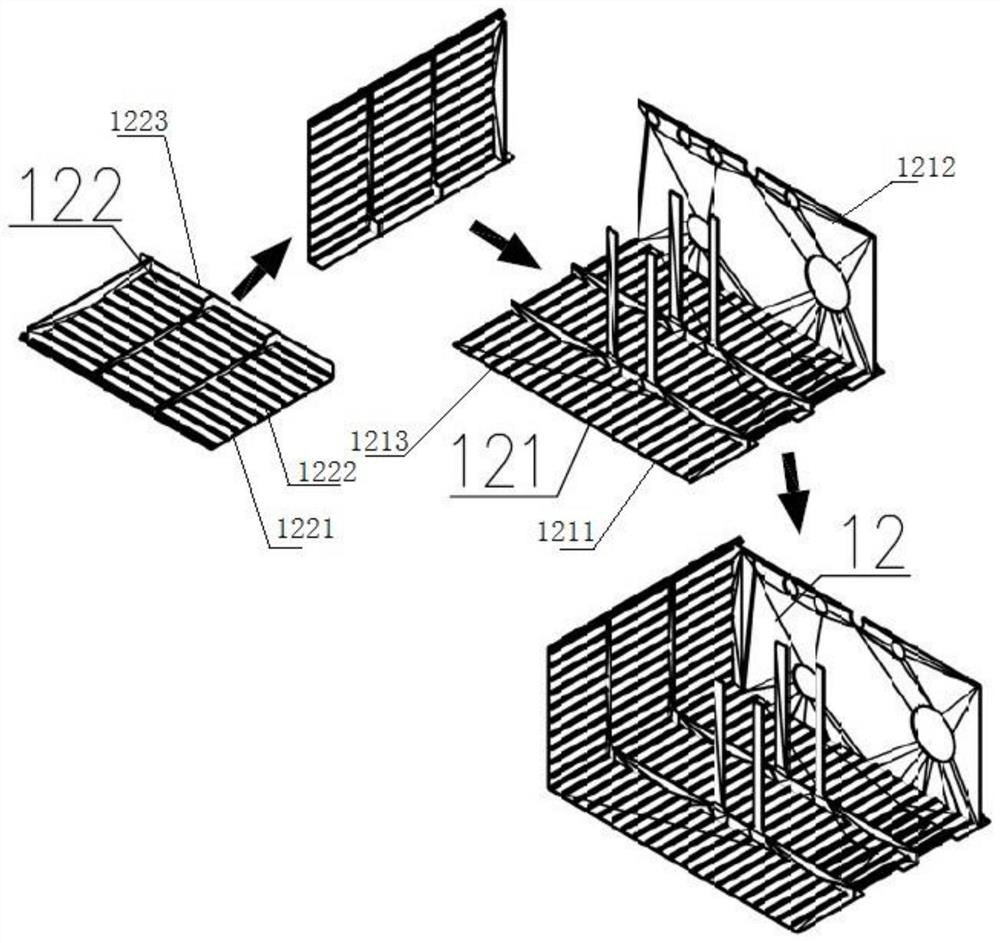

[0044] A segmented installation method for container ship scrubbers. According to the deck platform, the scrubbers are divided into upper and lower segments. When dividing, two points should be considered: first, the weight of the upper and lower segments meets the requirements for hoisting Bearing requirements, the second is to facilitate the hoisting of the scrubber equipment inside the scrubber; if the hoisting requirements are met, but the scrubber equipment installation requirements are not met, you can choose to open holes on the corresponding deck platform. In this embodiment, a 15,000TEU container ship The scrubber section as an example:

[0045]The scrubber equipment includes large-scale equipment such as the main engine desulfurization device 3, the generator desulfurization device 4, and the main engine SCR device 5. Since the main engine des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com