Vertical assembling method for structural modules of nuclear power plant

A technology for structural modules and nuclear power plants, which is applied in the construction of buildings, construction, and the processing of building materials, etc. It can solve the problems of different widths of weld gaps, out-of-tolerance openings or embedded boards, and non-parallel errors of lateral position lines. , to achieve the effect of high efficiency, light pollution and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Taking CA01, the most important structural module of the third-generation nuclear power plant, as an example, the present invention will be further described. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0035] The specific steps of the vertical assembly method for nuclear power plant structural modules provided in this embodiment are as follows:

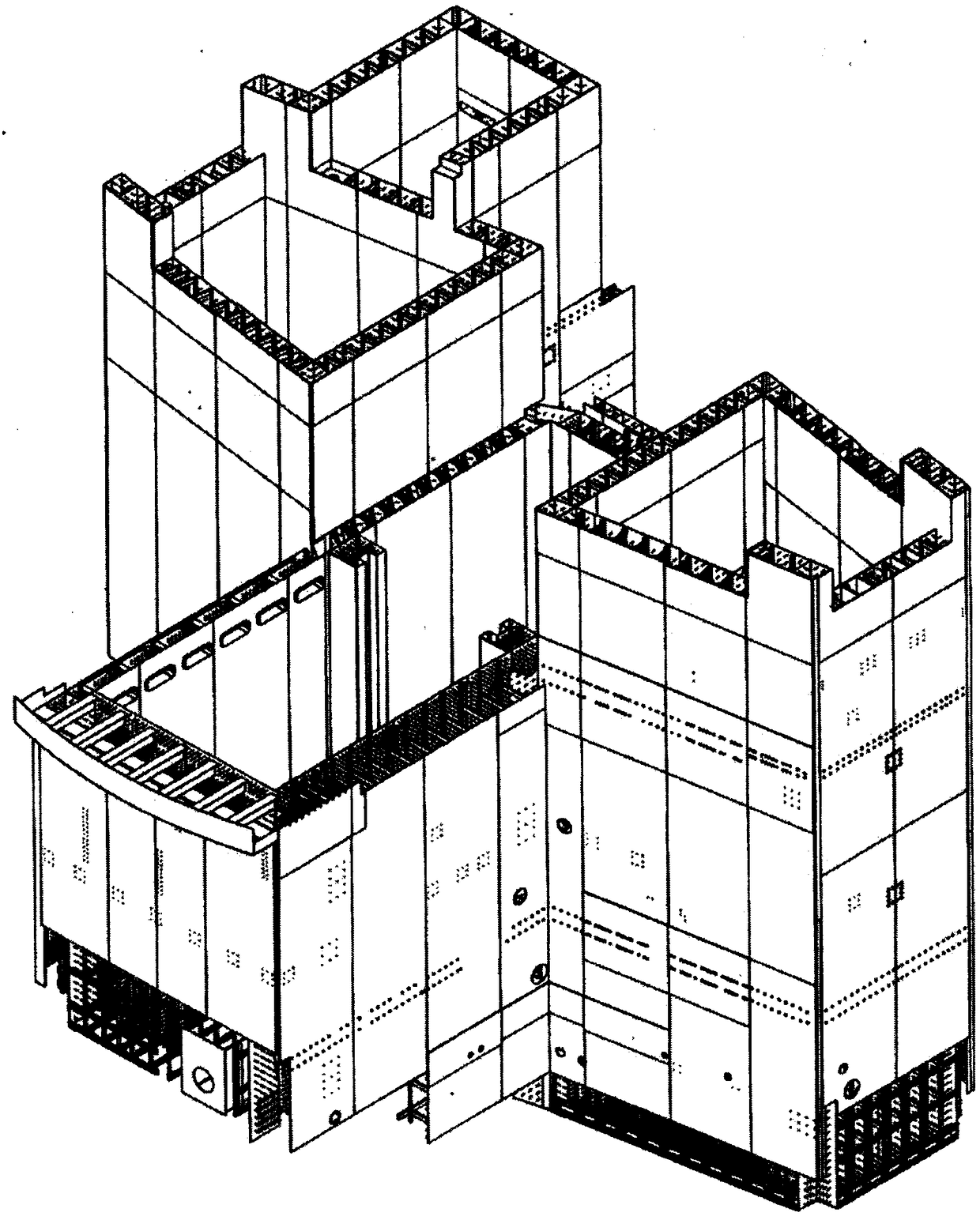

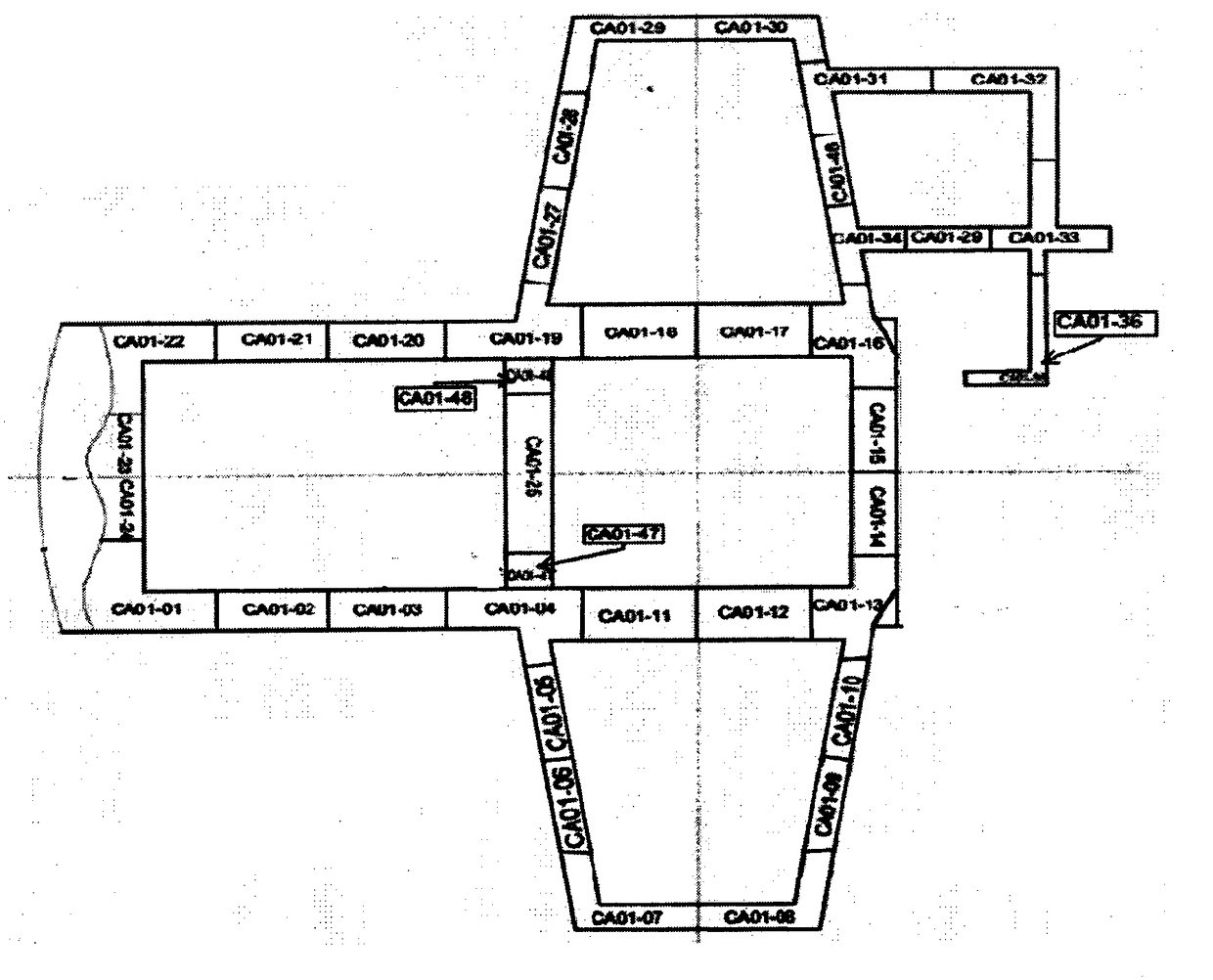

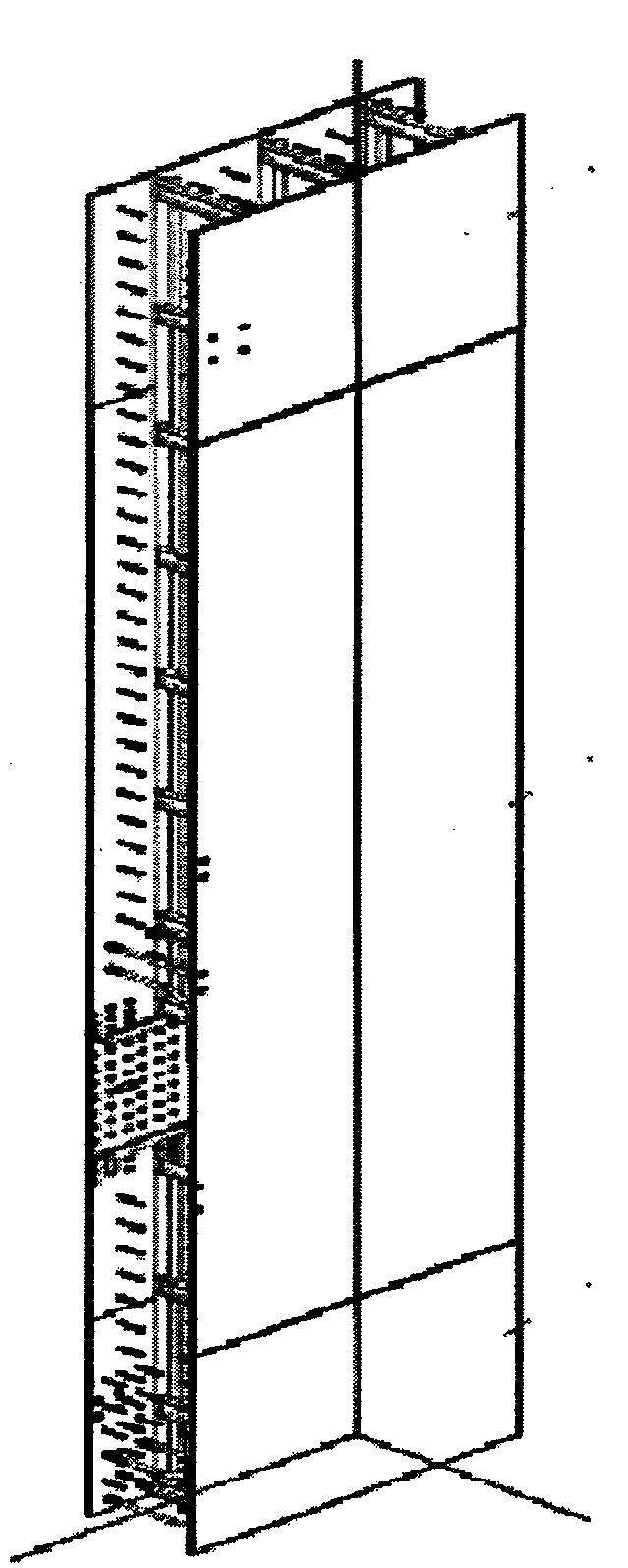

[0036] Split the CA01 structural module assembly with the sub-module as the basic unit. The schematic diagram of CA01 structural module is as follows: figure 1 As shown, the external dimensions of the CA01 structural module are 26.74 meters in length, 28.96 meters in width, and 23.47 meters in height, and the total weight of the structure is about 874t. For important rooms such as pools, the sub-module layout plan is as follows figure 2 As shown, the schematic diagram of a single sub-module is shown in image 3 shown.

[0037] In the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com