Spreader anti-sway controlling method of overhead traveling crane

An overhead crane and control method technology, applied in the directions of load hanging components, transportation and packaging, can solve the problems of complex structure, inconvenient maintenance, poor reliability, etc., and achieve high control accuracy, fast data processing, and good reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

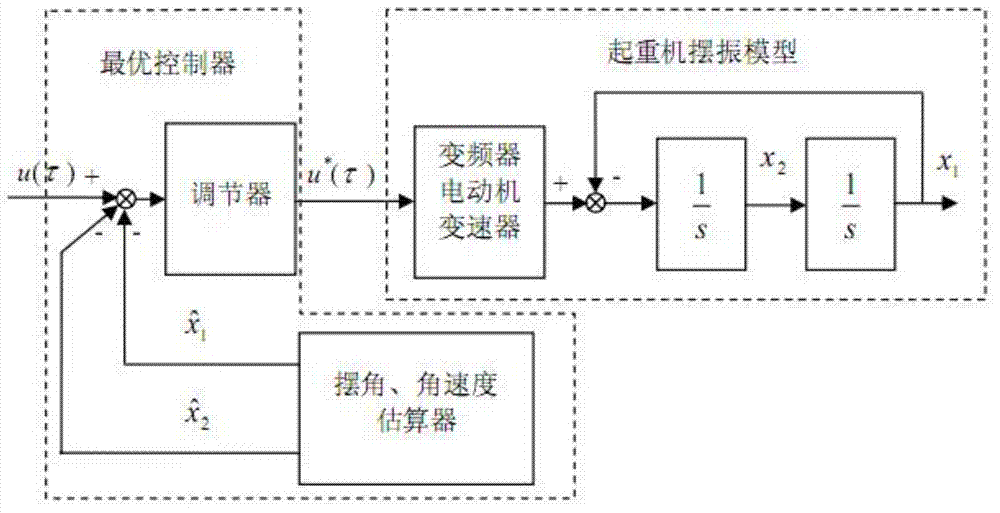

[0035] figure 1 The feed-forward anti-sway control algorithm is the basis.

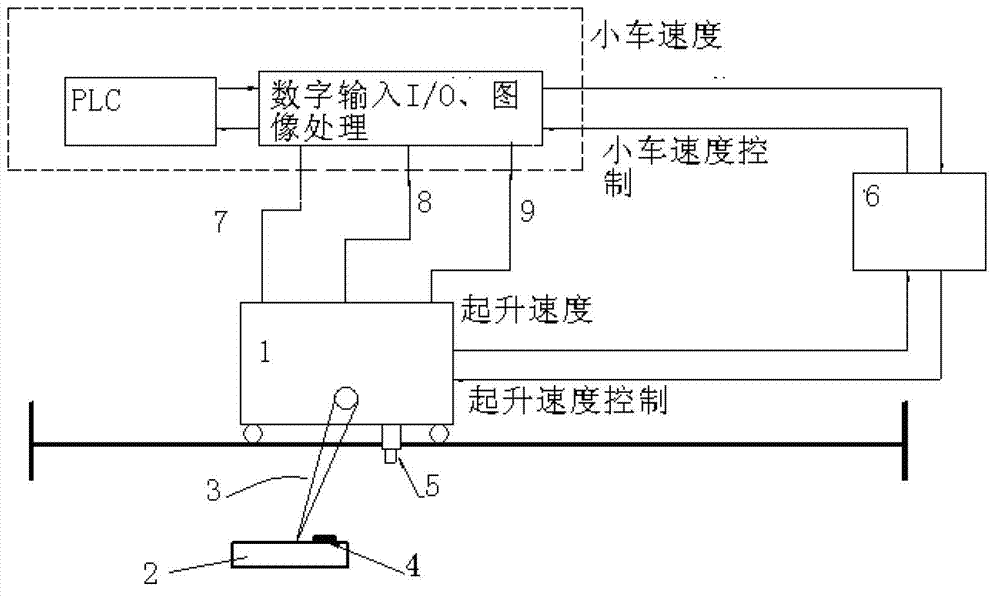

[0036] figure 2Shown is the device diagram, trolley 1, spreader 2, rope 3, camera mark 4, camera 5, frequency converter 6, trolley position detection 7, rope length detection 8, swing angle detection 9. The standard workshop is used for the experiment. The track is 23.5 meters long and 9 meters high. There are 5 measurement variables in the system: trolley position, rope length, swing angle, trolley speed and lifting speed. These five measurement variables are controlled by 2 absolute encoders. , VS710 camera system and incremental encoder measurement. The parametric speed control of the trolley and hoist acts on the AC servo motor to drive the whole system through the ABB frequency converter, so as to achieve the harmonious and coordinated work of the whole system. The control strategy and the processing of the collected measurement signals are implemented by the entire PLC processor. Various co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com