Loading dock seal

a technology for loading docks and seals, applied in the field of loading dock seals, can solve the problems of improper seals, preventing or making difficult a clean and complete seal against the loading dock entrance, and bulging outwards, and achieves the effect of convenient disassembly or attachment, and better assurance of seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A. Overview

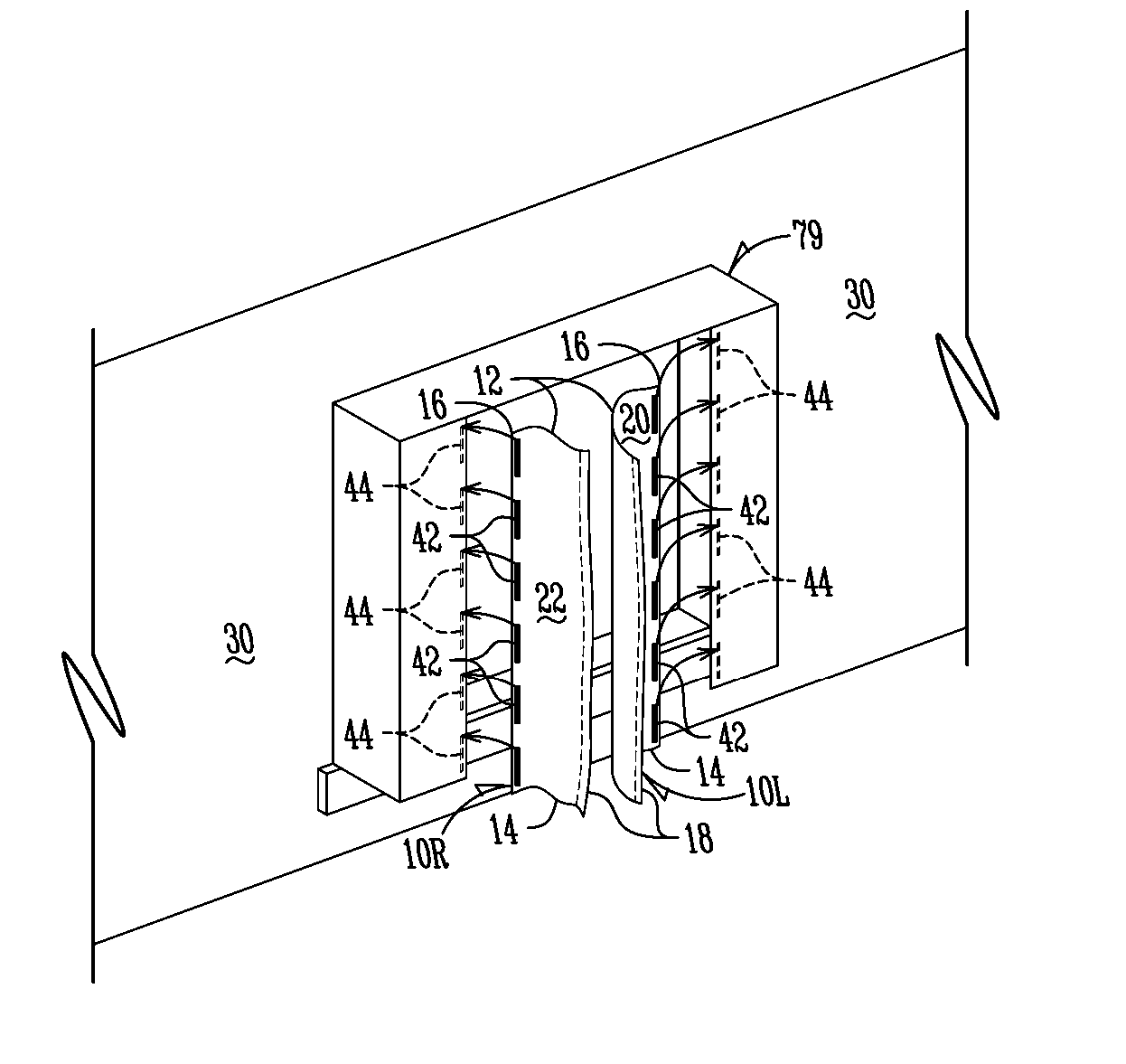

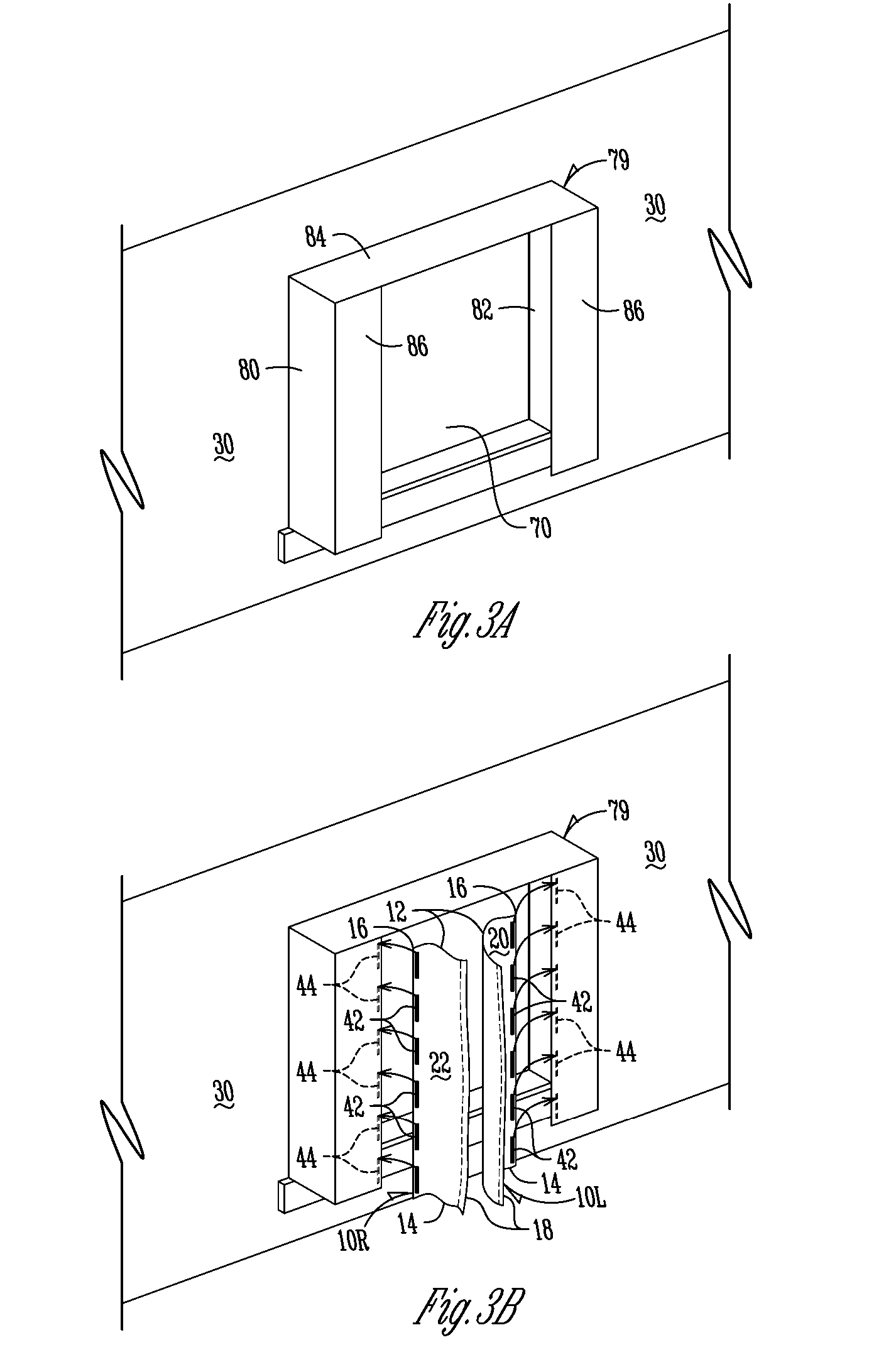

[0053] For a better understanding of the invention, several exemplary embodiments will now be described in detail. These are but several examples of forms the invention can take and are not exhaustive or limiting to the invention. The context of the invention will be with respect to conventional loading dock openings, dock shelters, and dock seals with pads or other similar structure, such as are well-known in the art, examples of which are shown in the patents referenced earlier and shown in some of the drawings (e.g., FIGS. 1, 2, 3A, 4A, 5A, and 6A). It can be appreciated that the invention is applicable to analogous uses also. It is not intended that the present invention be limited to the described embodiments. It is intended that the invention will cover all modifications and alternatives, which may be included within the spirit and scope of the invention.

B. Background

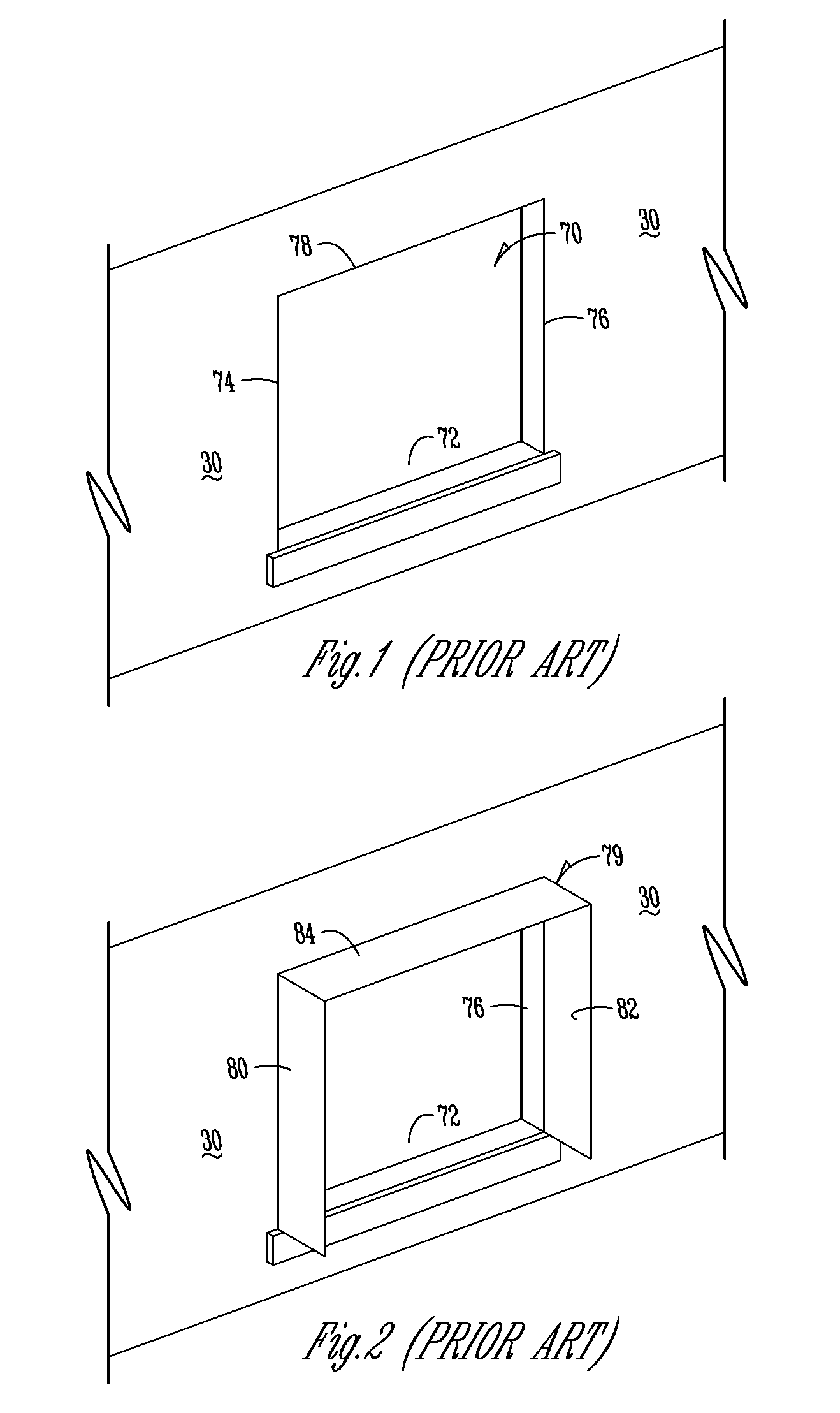

[0054]FIG. 1 discloses a loading dock. The loading dock is essentially an opening 70 within a wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com