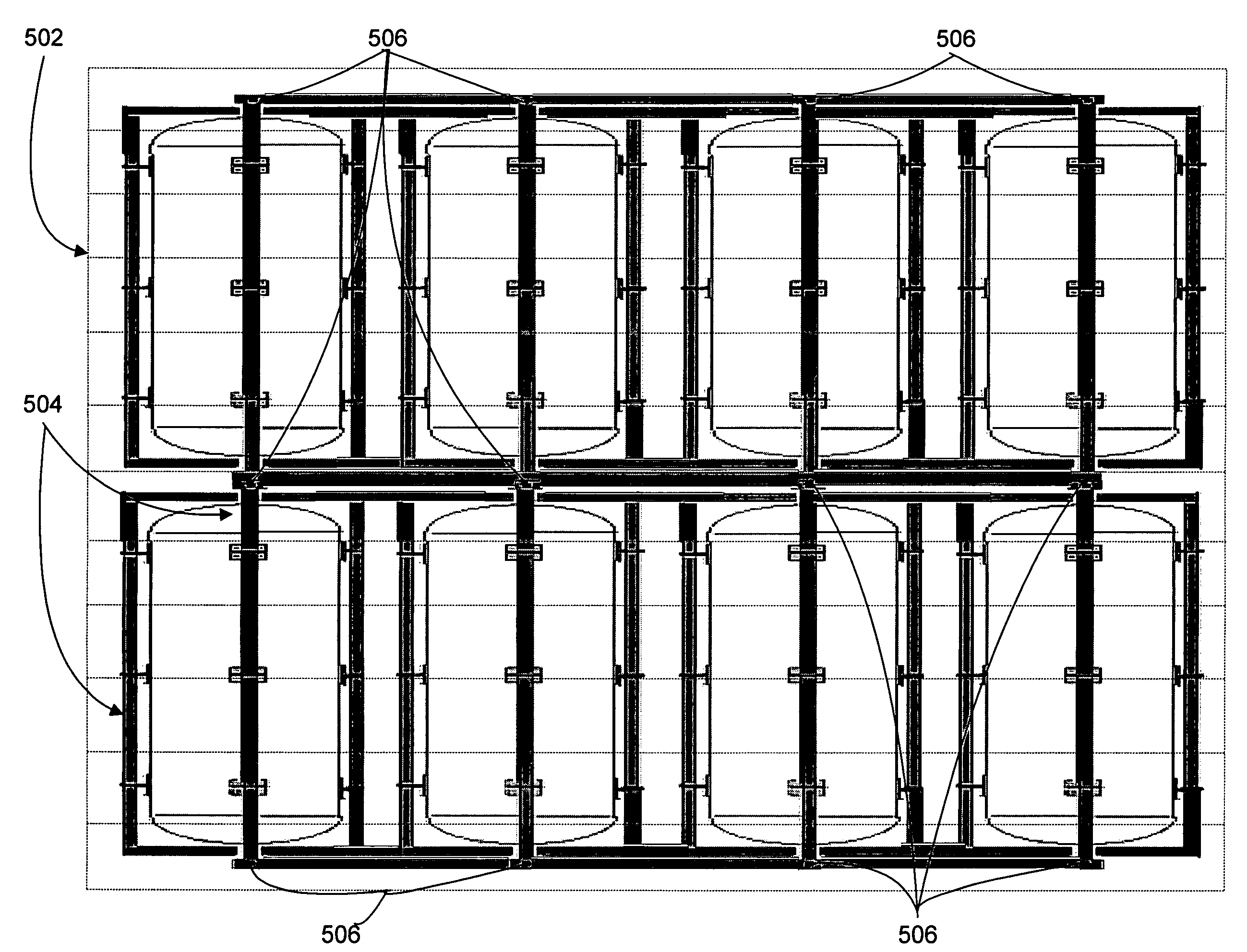

Modular floating dock with inflatable pontoons

a floating dock and pontoon technology, applied in the field of floating docks, can solve the problems of floating dock technology, difficult or impractical delivery, and difficulty in securing a fixed dock, and achieve the effect of simple modular configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

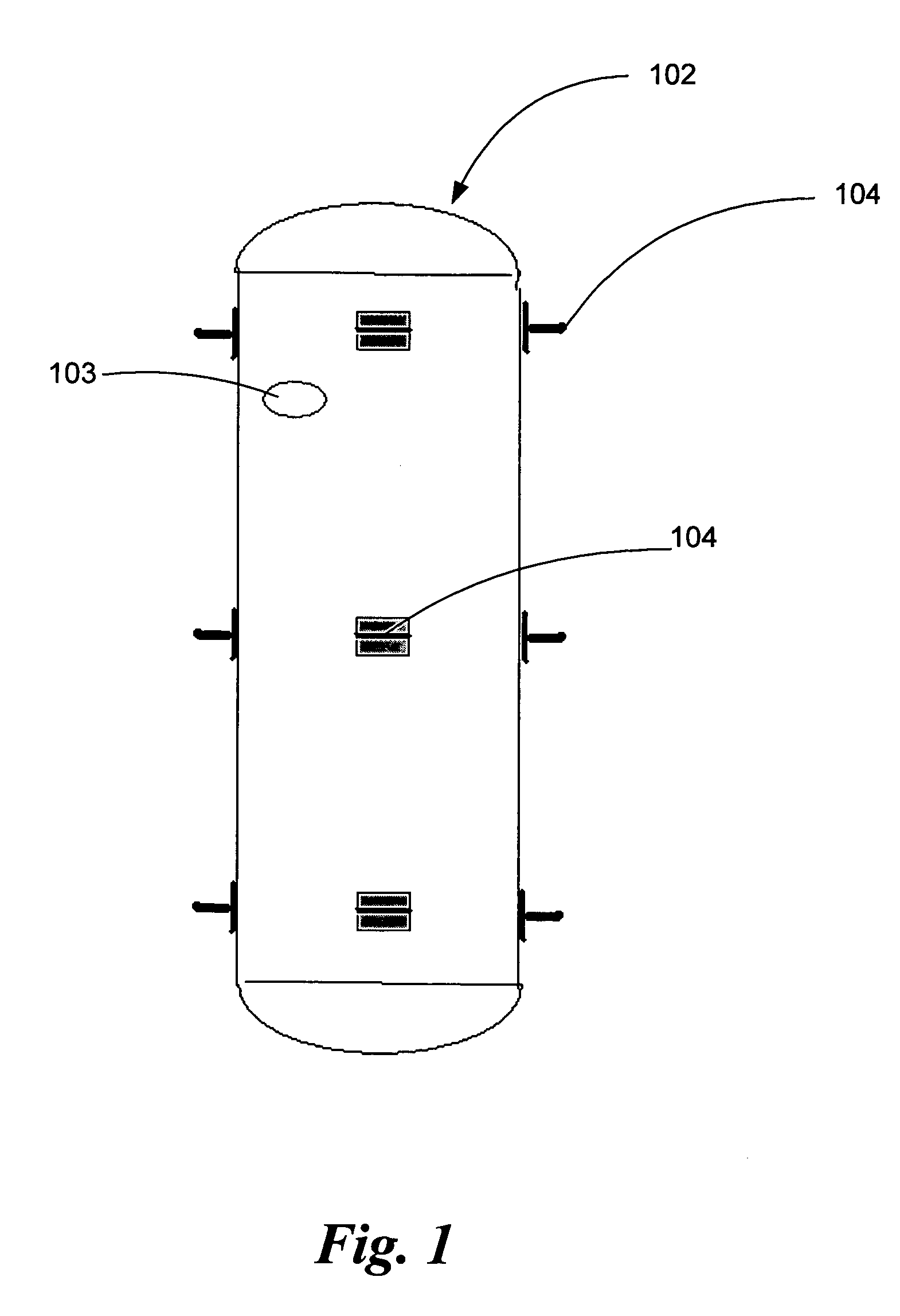

[0018] Referring to FIG. 1, illustrated is an inflatable pontoon module according to the present invention. Pontoon 102 comprises a tube of polymer coated fabric material, with closed ends of the same or similar material, made airtight. Pontoon 102 is further fitted with valve 103 for inflation and deflation in the manner of inflatable rafts of rubberized fabric, well known to those in the art. In preferred embodiments, pontoon 102 comprises a plurality of chambered sections, so that in the event of a rupture, the pontoon will still retain partial buoyancy.

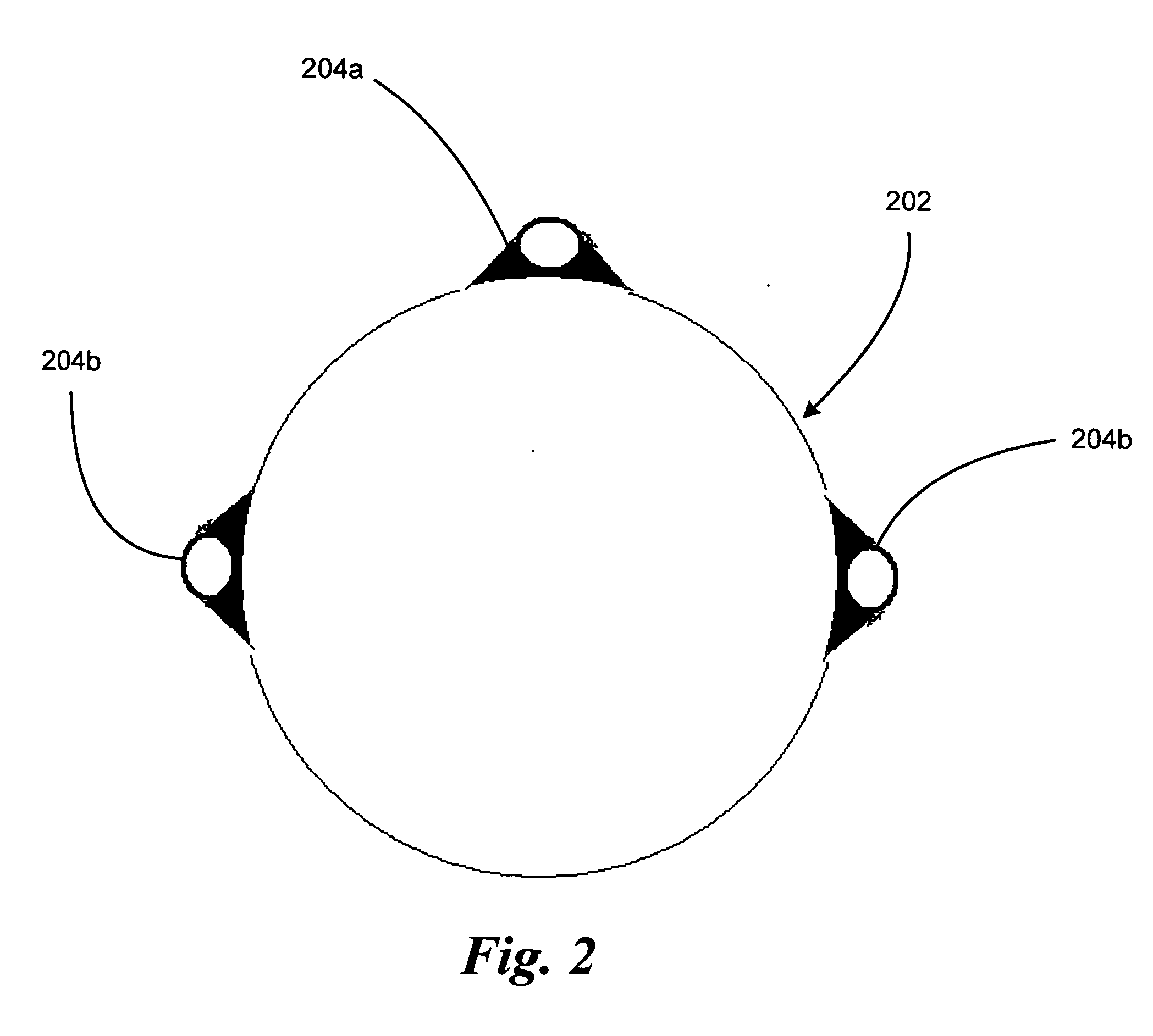

[0019] Affixed to pontoon 102 are a number of annular components 104, arranged in groups to form lines along the surface of pontoon 102 parallel to the main axis of the pontoon, as will be described in greater detail in the following passages in reference to the other figures in this specification.

[0020] Annular components 104 are comprised of a relatively rigid and durable material, such as metal or plastic, suitable for prolon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com