Cyclic transport device

A transmission device and conveying device technology, which is applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of high control system cost, pinched workers' fingers, and high procurement cost of transfer boxes, and achieves mechanical structure and control system. Simple, low cost, and the effect of realizing the automatic operation of the assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

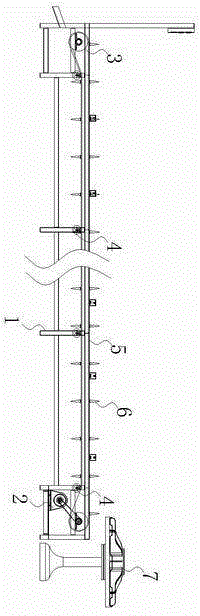

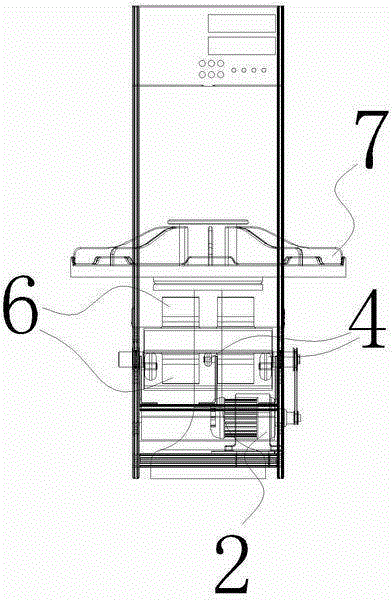

[0024] See figure 1 with figure 2 , a circulation transmission device, comprising:

[0025] A conveying device for transporting objects to be conveyed; the conveying device includes a conveyor belt 5 and a driving device, the conveyor belt 5 is provided with a partition 6 for isolating the conveyed objects, and the driving device includes a conveyor belt 5 two ends and A conveying roller 3 that is passed around by the conveying belt and a drive motor 2 that drives said conveying roller.

[0026] The driving device is also provided with a tensioning device, and the tensioning device is provided with a gap for the partition to pass through. The tensioning device is at least one tensioning roller 4 arranged under the lower layer of the conveyor belt, the number of which is determined according to the length of the circulation transmission device, and the length of the circulation transmission device is determined according to the actual production of the factory.

[0027] The...

Embodiment 2

[0030] The rest are the same as in Embodiment 1, except that the tension roller 4 includes side tension rollers arranged on both sides of the conveyor belt 5 and a middle tension roller arranged in the middle of the conveyor belt, and a middle tension roller is arranged in the middle of the partition plate. There is a notch matching the width of the intermediate tension roller. This can make the tension roller 4 better support the very tensioned conveyor belt 5, and make the system run more smoothly.

Embodiment 3

[0032] The rest is the same as that of Embodiment 2, except that the partition 6 includes a riser and a detachable base capable of adjusting its position on the conveyor belt, and the riser is fixed or movably connected to the base. In this way, the distance between the partitions can be adjusted conveniently according to the production process and production cycle, which makes the system more adaptable and reduces the corresponding investment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com