Grinding, cleaning and drying integrated machine for baseball bats

An all-in-one machine and bat technology, which is applied in dryers, drying machines, progressive dryers, etc., can solve the problems of low efficiency and inability to meet the needs of large-volume production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

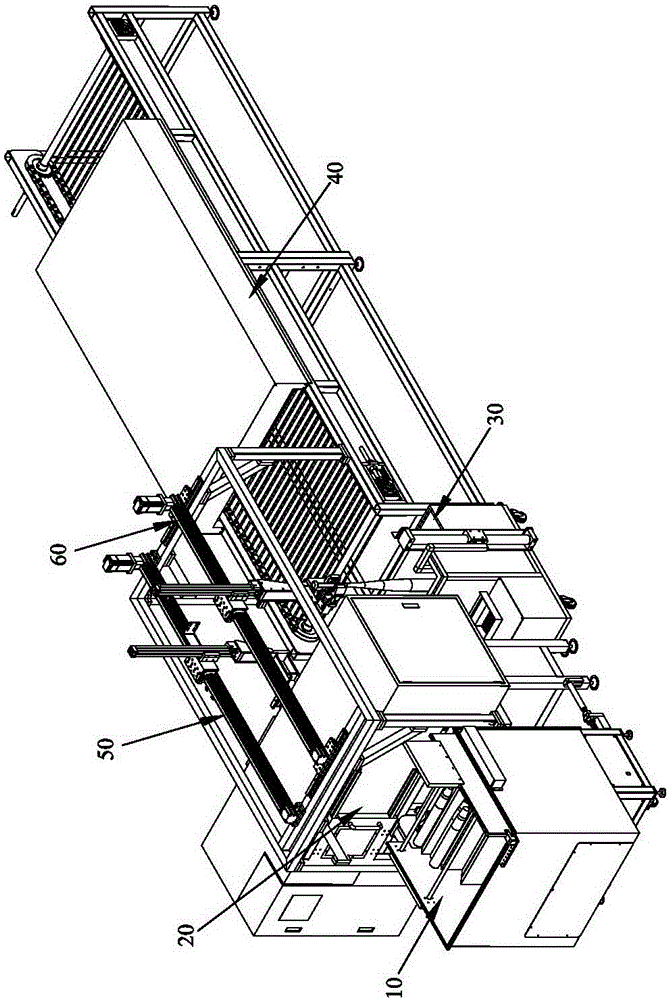

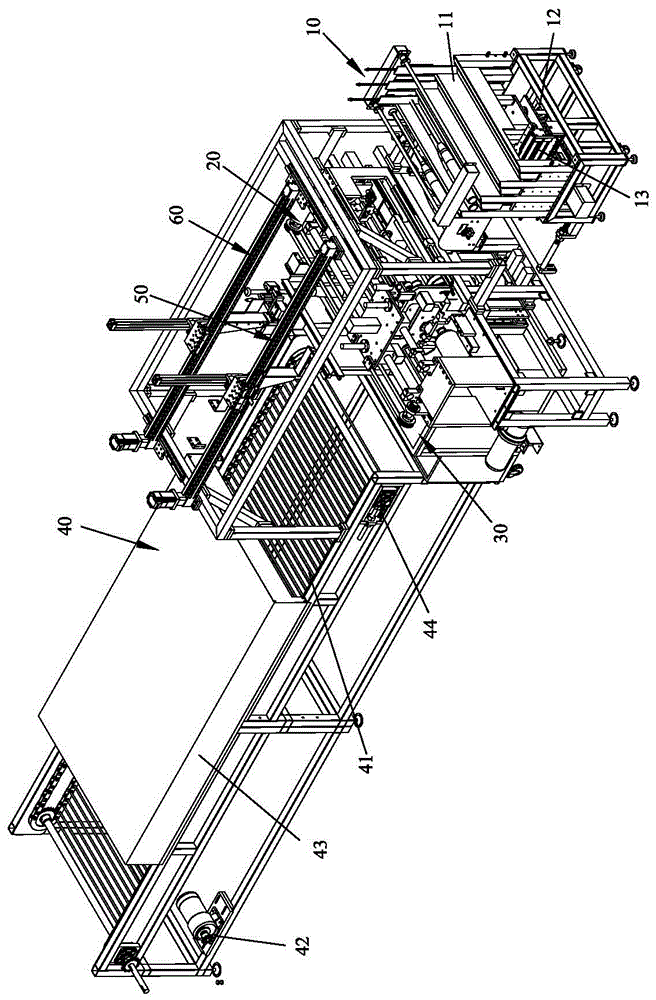

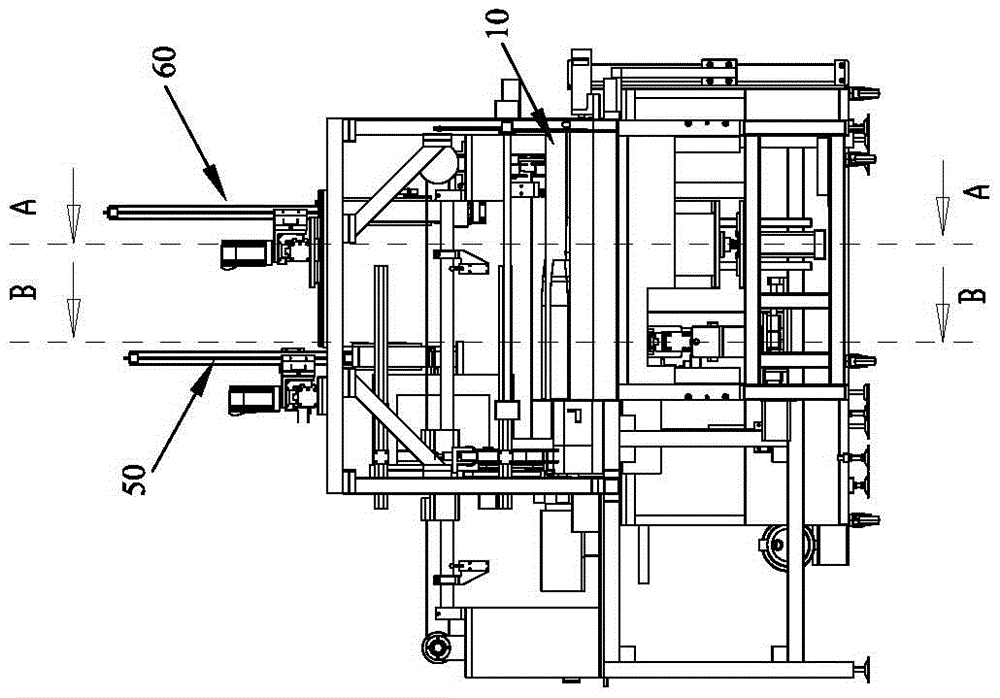

[0061] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the preferred embodiment of the present invention. It is a grinding, washing and drying machine for bats. Since the surface of the baseball bat is relatively rough after production, it needs to be polished to make it smooth. The working process of the all-in-one machine of the present invention is: automatic loading of baseball bats, after reaching the grinding station A, the surface is polished with sandpaper, and after polishing, one of the manipulators is used to send it to the transfer station B, and then another manipulator is used to send it to the cleaning station. Station C sprays with water to remove impurities on the polished surface, and finally sends it to drying station D for drying treatment and unloading. The above-mentioned whole process does not require manual participation, realizes automatic operation, and achieves the purpose of reducing labor costs and improving produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com