Single-crystal bar disconnection cutting equipment

A technology of cutting equipment and single crystal ingot, which is applied in the direction of metal processing equipment, stone processing equipment, grinding/polishing equipment, etc., can solve the problems of long time-consuming replacement of cutting wire, complicated wire-feeding mechanism, and large impact on precision, etc. Easy disconnection, low labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

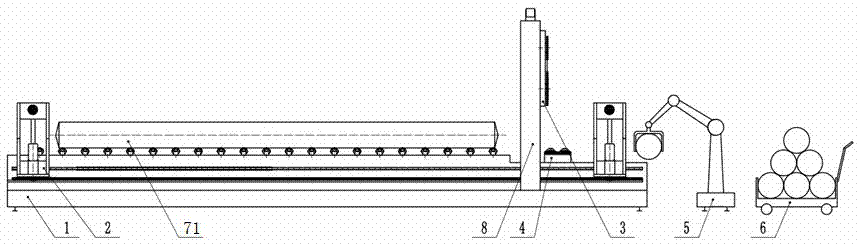

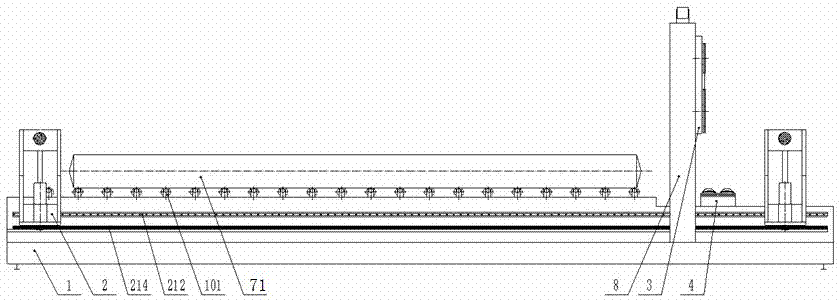

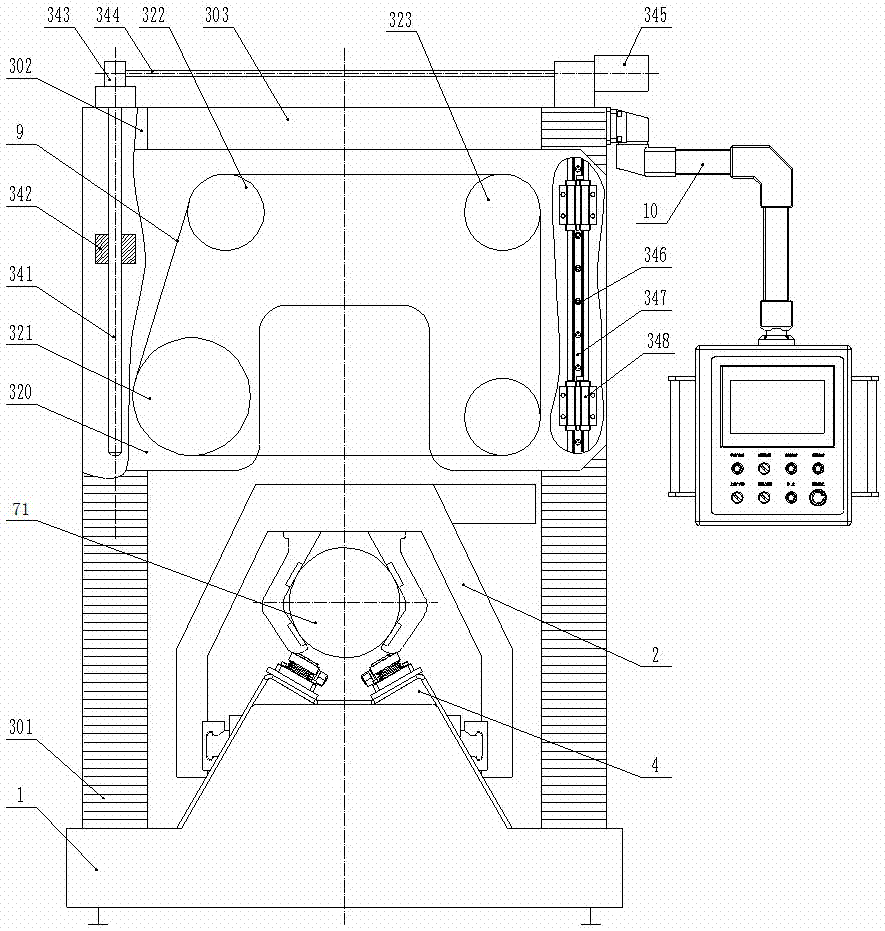

[0027] Such as Figure 1-7 As shown, a single crystal bar truncation and cutting equipment includes a frame, a single crystal bar feeding device that can slide on the bottom frame, a cutting frame installed on the bottom frame, and a wire installed on the cutting frame A sawing mechanism, a single crystal bar support device that can slide on the bottom frame, a feeding robot and a material truck, the bottom frame includes a base 1, and several support roller assemblies 101 on a fixed base, and the support roller assemblies are located on the cutting frame The left side of the base is installed on the "V"-shaped table of the base 1, and each two are symmetrically fixed in a group to form a support angle. The single crystal bar is placed on the support mechanism; the linear guide A212 and the rack A214, rack A214 cooperates with the gear in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com