The coil feeding device of the automatic elastic head machine and the automatic elastic head machine

A feeding device and a technology for rolling elastic bands, which are applied in cloth feeding mechanisms, sewing machine components, textiles and papermaking, etc., can solve the problems of low efficiency of manual coiling, difficulty in stitching with ordinary sewing machines, and inability to ensure uniform quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

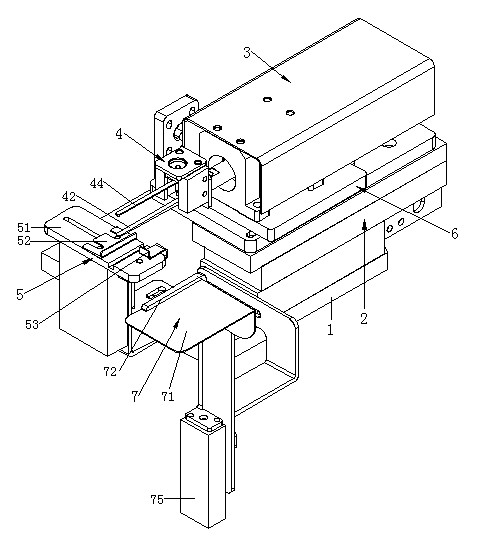

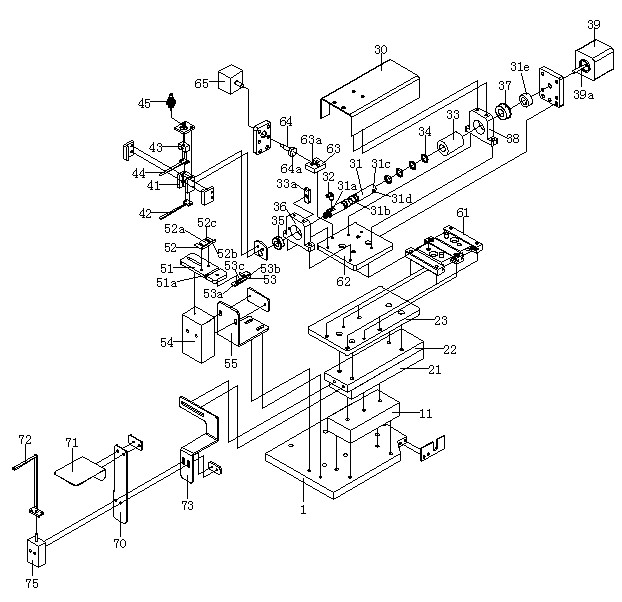

[0021] The coil material feeding device of the automatic rolling elastic head machine of the present invention comprises a mounting plate 1, on which a guide slide 2 is fixedly arranged, and the guide slide 2 includes a base 21 with a stroke sensor and is slidably arranged on the base Slide table 22 on 21. A rotating mechanism 3 is fixedly arranged on the slide table 22 . The rotating mechanism 3 includes a bracket and a rotating shaft 31 driven by a first driving mechanism. The rotating shaft 31 is connected with a clamping mechanism 4 . The clamping mechanism 4 includes a slide rail 41 fixed on the end of the rotating shaft 31, a constant pressure plate 42 is fixed on the slide rail 41, a slide block 43 is slidably arranged in the slide rail 41, and the slide block 43 is fixedly provided with a movable pressure plate 44. 41 is fixedly connected with the presser foot cylinder 45 for driving the slider 43 to reciprocate.

[0022] A first air hole 31 a and a second air hole 31...

Embodiment 2

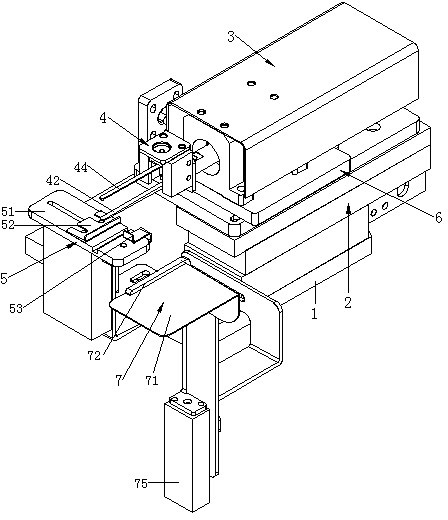

[0037] The following is Example 2. This embodiment is a simplified implementation of Embodiment 1, and the sliding mechanism 6 and the pressing mechanism 7 in Embodiment 1 are omitted.

[0038] The coil feeding device of the automatic rolling elastic head machine of the present embodiment includes a mounting plate 1, on which a guide slide 2 is fixedly arranged, and the guide slide 2 includes a base 21 with a stroke sensor and is slidably arranged on The slide table 22 on the base 21. The slide table 22 is driven by an air cylinder and slides on the base 21, and the stroke sensor can detect the position of the slide table 22.

[0039] A rotating mechanism 3 is fixedly arranged on the slide table 22 . The rotating mechanism 3 includes a bracket and a rotating shaft 31 driven by a first driving mechanism. The rotating shaft 31 is connected with a clamping mechanism 4 .

[0040] The clamping mechanism 4 includes a slide rail 41 fixed on the end of the rotating shaft 31, a const...

Embodiment 3

[0047] The automatic rolling elastic head machine of the present invention includes a machine head, a sewing mechanism arranged on the machine head, and the coil feeding device as described in Embodiment 1 or Embodiment 2. The machine head is equipped with a matching presser foot at the conveying position of the coil material feeding device. When the coil material feeding device sends the wound rubber head to the bottom of the presser foot, the presser foot of the automatic rolling rubber head machine presses it The elastic head, the sewing mechanism will sew and fix the elastic head, and then the material can be discharged through the discharge device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com