Track sucking disk type gripping device

A suction cup and track technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of unstable grasping position, inflexible operation, high manufacturing cost, etc., and achieve high accuracy, simple overall structure, and not easy to wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

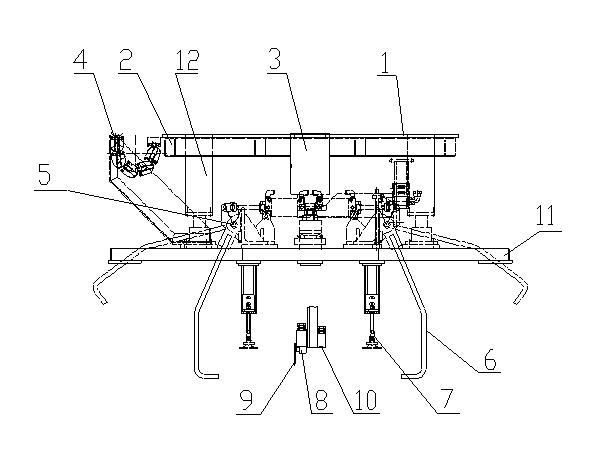

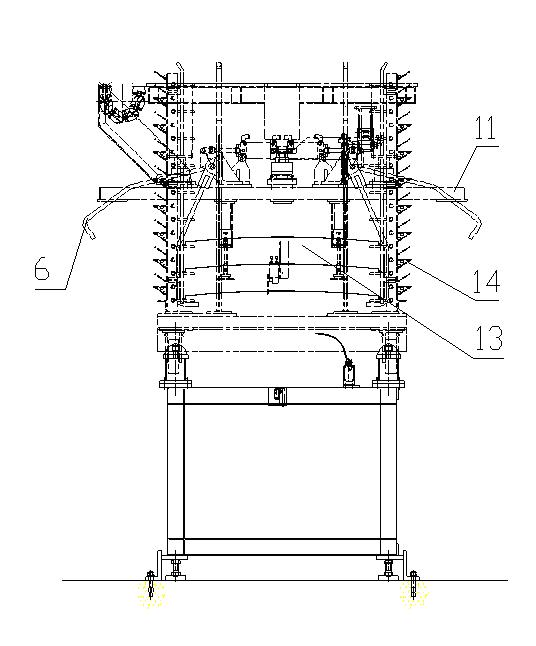

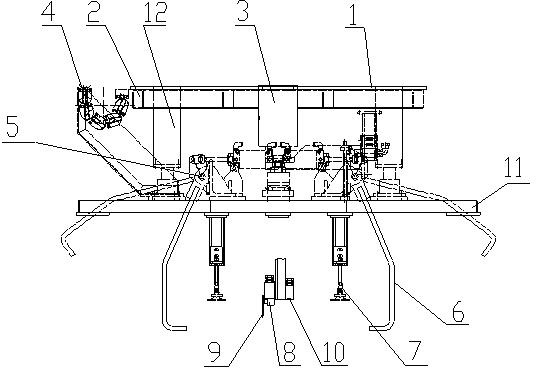

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0019] see figure 1 , the present embodiment is a kind of track sucker type grabbing device, establishes a platform type fixed top beam 1, this fixed top beam 1 is track type, is provided with the walking mechanism of gear, rack and fixed top beam 1 in the fixed top beam 1 2. The fixed top beam 1 runs on the assembly line track set by the automobile welding factory. The side of the fixed top beam 1 is equipped with a cable assembly 4. The cable assembly 4 can provide signals for the suction cup type grabbing device of this track. And the input and output of electric power; Parallel with fixed top beam 1, be provided with catch material bracket 11, this grab material bracket 11 plays the installation effect of whole grab material device; Between fixed top beam 1 and grab material bracket 11 The middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com