Turret type three-dimensional goods storage rack and automatic goods storing and taking method

A storage rack and turret-type technology, which is applied in the field of intelligent storage and retrieval of goods, can solve the problems of inability to realize automation, intelligent storage and retrieval, troublesome storage and retrieval, and dependence on labor, etc., to achieve automatic operation, wide application range, parking The effect of convenient car pickup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

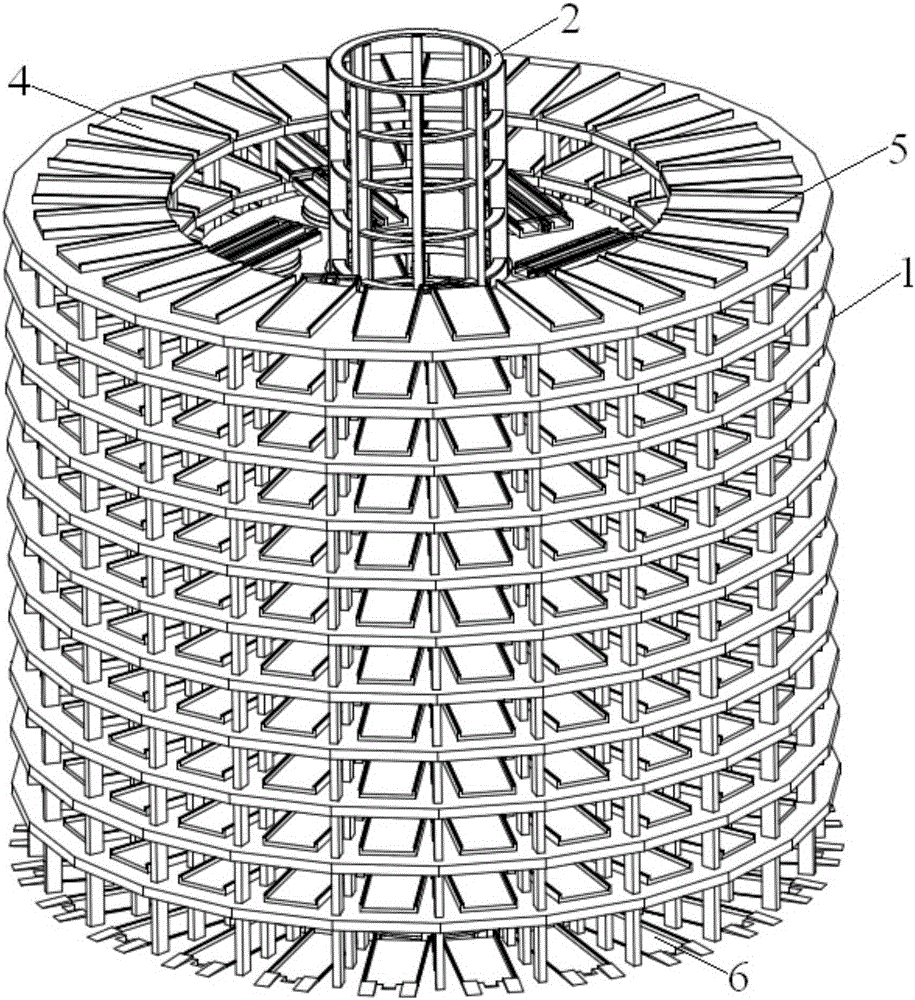

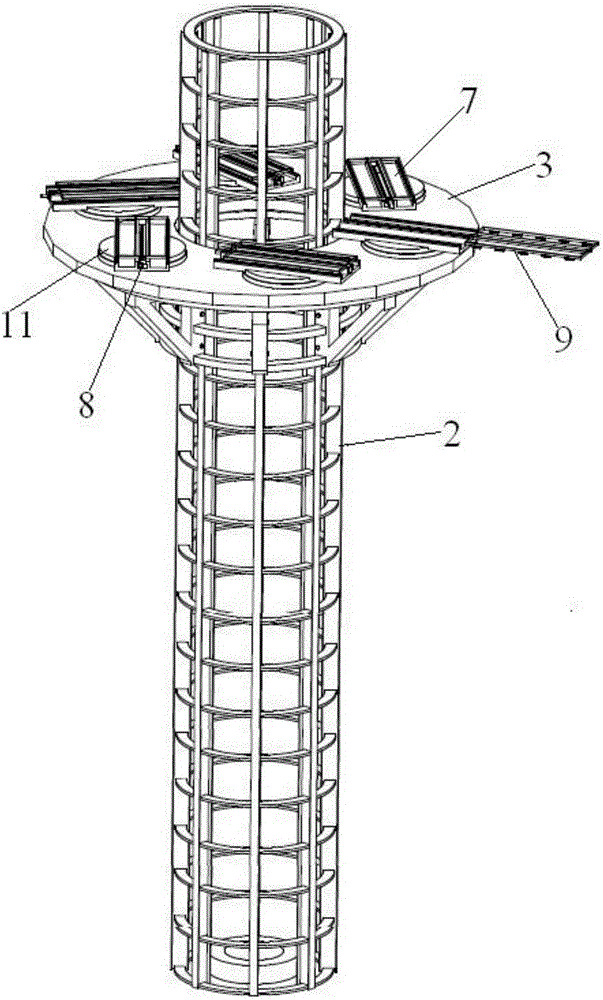

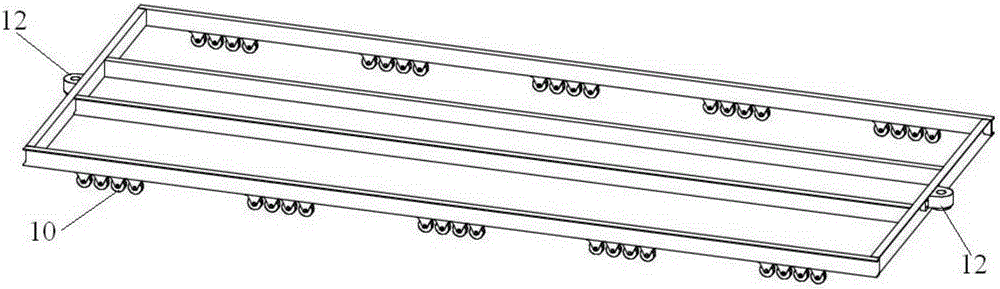

[0027] The overall structure of the turret type three-dimensional storage rack based on the automatic access method for goods provided by the present invention is as follows: figure 1 As shown, it includes at least a multi-layer annular shelf 1, a lifting tower 2 located at the center of the shelf, and a lifting platform 3 that is installed on the lifting tower and moves up and down along the lifting tower. It is a frame structure and has at least two layers. Any layer of the shelf is level with the ground, and this layer is the access layer, and the rest of the layers are storage layers, and the storage layers are evenly distributed along the circumferential direction. There are storage warehouses 4, the directions of the storage warehouses are all towards the center of the circle, rails 5 are arranged on the storage warehouses, transition cargo spaces 6 are uniformly distributed along the circumferential direction in the in-out layer, and rails are arranged on the transition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com