Ultra-fine grinding device for powder coating

A grinding device and powder coating technology, applied in grain processing and other directions, can solve the problems of cumbersome steps, fixed grinding gap, increased production cost, etc., to achieve extremely fine and uniform particle size, ensure uniformity, and excellent grinding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

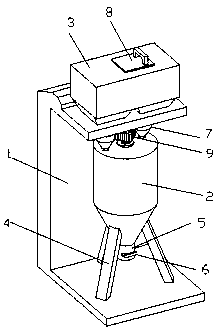

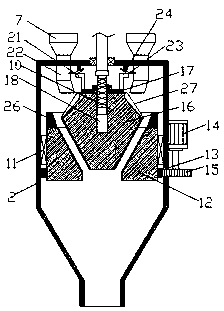

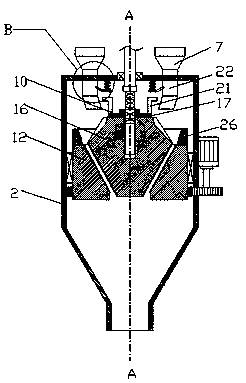

[0033] Embodiment 1 specifically introduces a kind of powder coating ultra-fine grinding device, as attached Figure 1~6 As shown, the main structure includes a fixed frame 1, a grinding cylinder 2 and a storage bin 3, and three legs 4 are arranged at the lower end of the grinding cylinder 2, and the legs 4 are welded to the bottom of the fixed frame 1, and at the bottom of the grinding cylinder 2 A discharge pipe 5 is connected, and a pull-out baffle 6 is arranged on the discharge pipe 5 . Its storage bin 3 is arranged on the top of the fixed frame 1, and the left and right ends of the lower surface of the storage bin 3 are connected with a feed hopper 7, and its feed hopper 7 is connected with the upper surface of the grinding cylinder 2, and the There is a transparent observation window (not shown in the figure) on the warehouse 3, and a feeding port is provided at its upper end, and a cover plate 8 is arranged on the feeding port, and the amount of raw materials inside the...

Embodiment 2

[0039] Embodiment 2 is to make further improvements on the basis of Embodiment 1, and its main improvements are as attached Figure 7~9 As shown, a filter screen 28 is rotated below the rotating ring-shaped grinding block 12, and a fixed block 29 is welded on the inner wall of the grinding cylinder 2 below the filter screen 28, and the fixed block 29 is connected with the screen frame of the filter screen 28. The vibrating spring 30 is connected to the lower end of the movable round table grinding block 16. When the movable round table grinding block 16 moves downward under the action of the reciprocating screw rod 10 and the sliding sleeve 17, the resisting rod 31 touches the filter screen One end of 28 makes screen pack 28 incline. And on the grinding cylinder 2 below filter screen 28 inclined ends, be connected with coarse particle passage 32, be provided with auger conveyer 33 on the outer surface of grinding cylinder 2, its auger conveyer 33 vertically upwards arrange, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com