Cement raw material additive, application thereof and cement production process

A cement raw material and additive technology, applied in cement production, etc., can solve problems such as high environmental pressure, high COD, and environmental impact, and achieve the effects of improving material fluidity, increasing output, and realizing comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

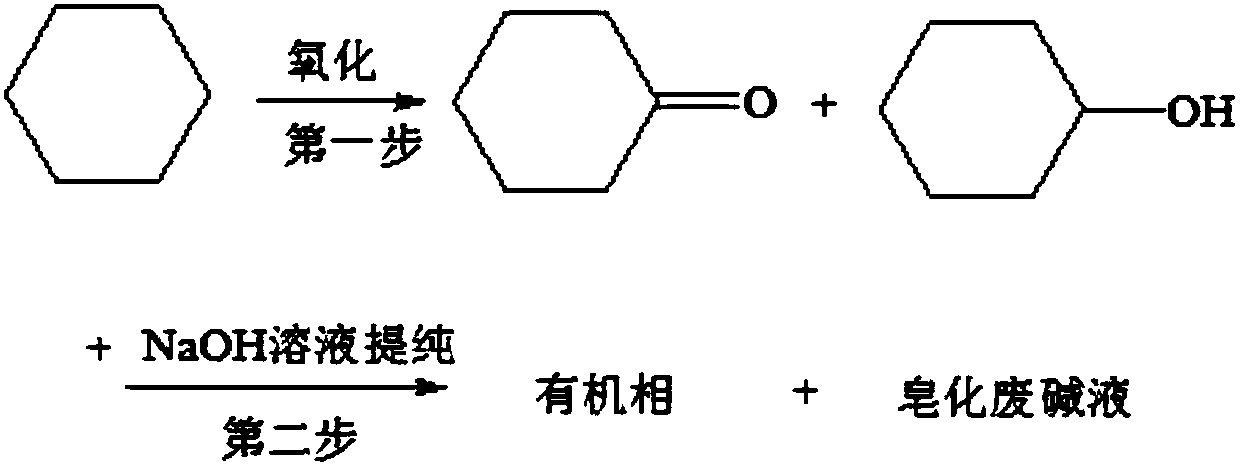

Method used

Image

Examples

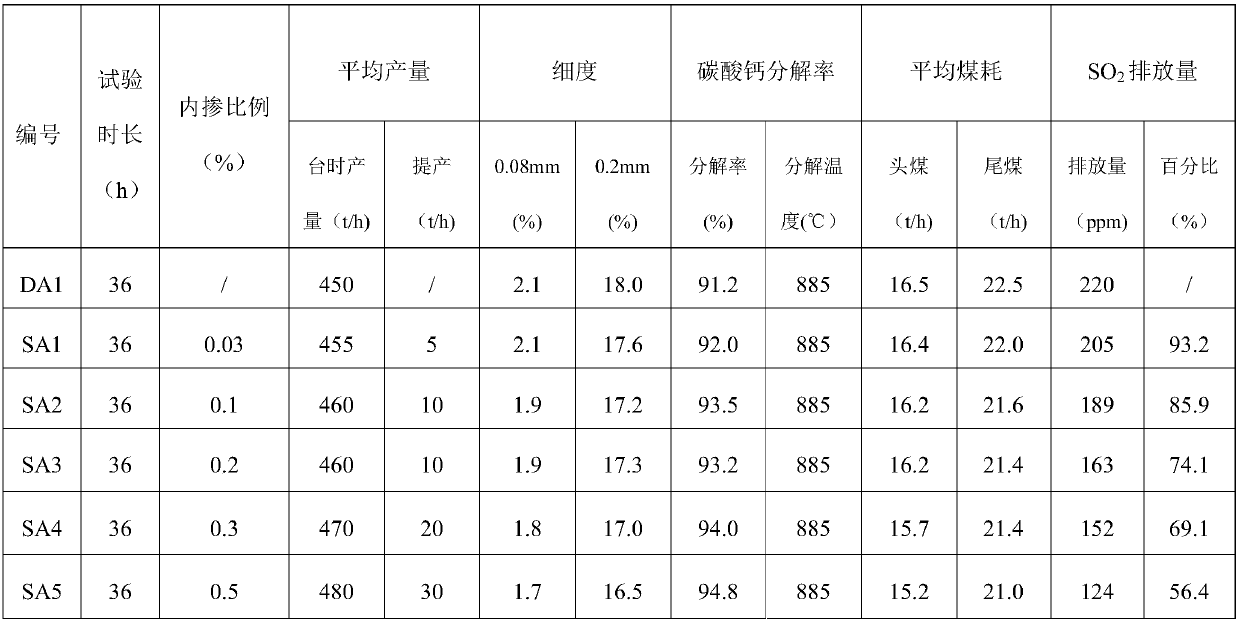

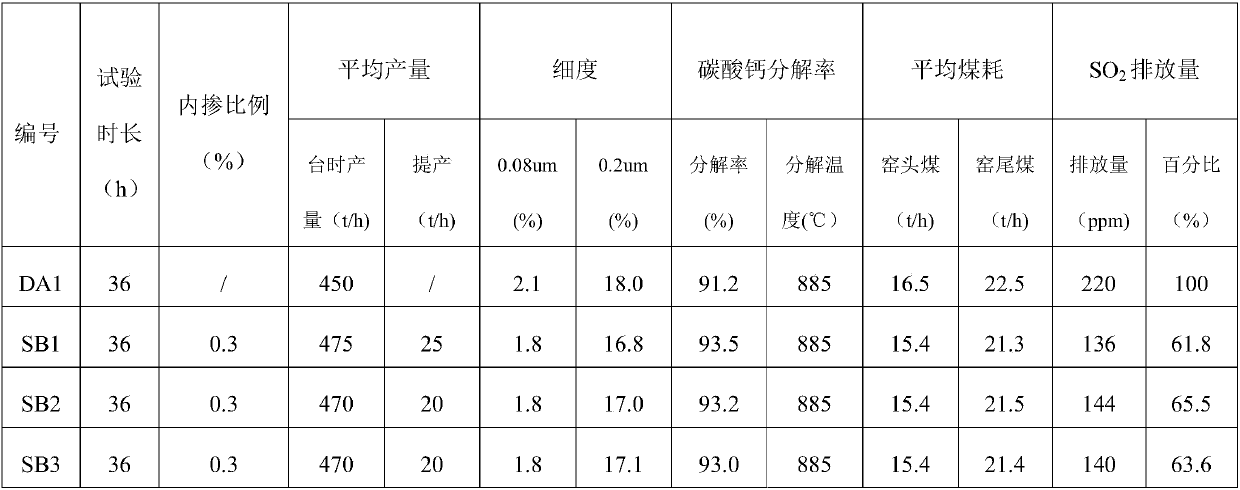

Embodiment SA1

[0051] Liquid A (100 parts by weight) was mixed with raw meal to be ground with cement at a ratio of 0.03% by weight for raw meal grinding and calcination. The specific conditions and results are shown in Table 1.

Embodiment SA2

[0053] Liquid A (100 parts by weight) was mixed with raw meal to be ground with cement at a ratio of 0.1% by weight for raw meal grinding and calcination. The specific conditions and results are shown in Table 1.

Embodiment SA3

[0055] A solution (100 parts by weight) is added to 70 parts by weight of an alkalinity enhancer (sodium hydroxide) as a cement raw meal additive, and the raw meal to be ground is mixed with cement in a proportion of 0.2% by weight for raw meal grinding and calcination. The specific conditions and results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com